Preparation method of micromolecular pectin

A technology for small molecules and pectin, applied in the field of preparing small molecule pectin, can solve the problems of difficult recovery of anhydrous ethanol, low yield of small molecule pectin and high cost, and achieve stable molecular weight, easy reaction control and large output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

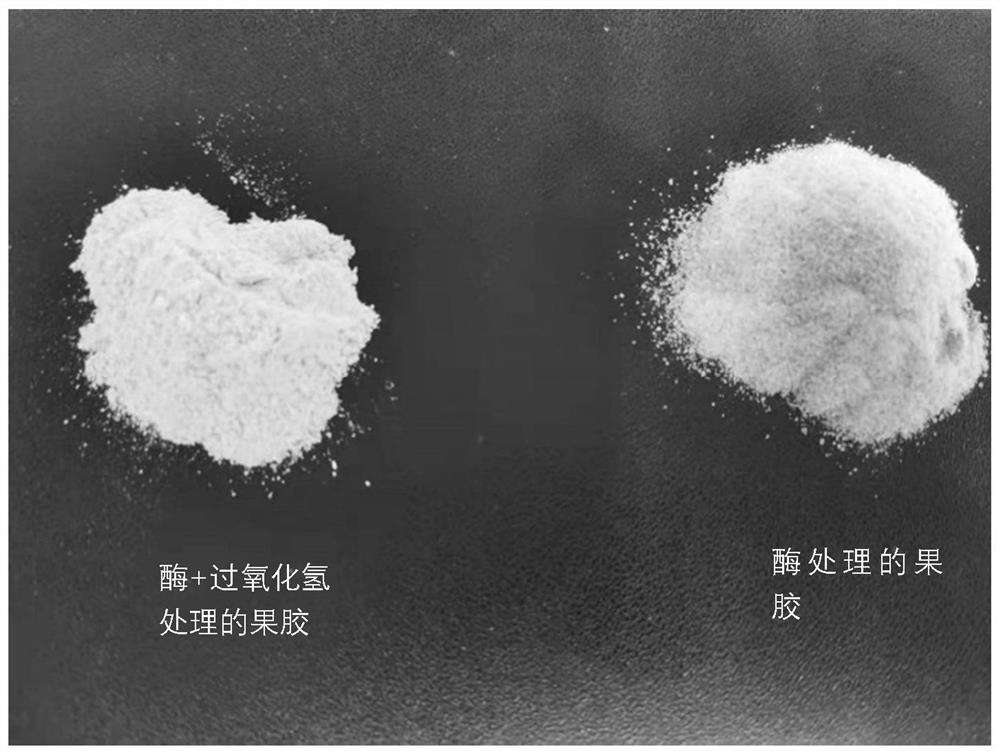

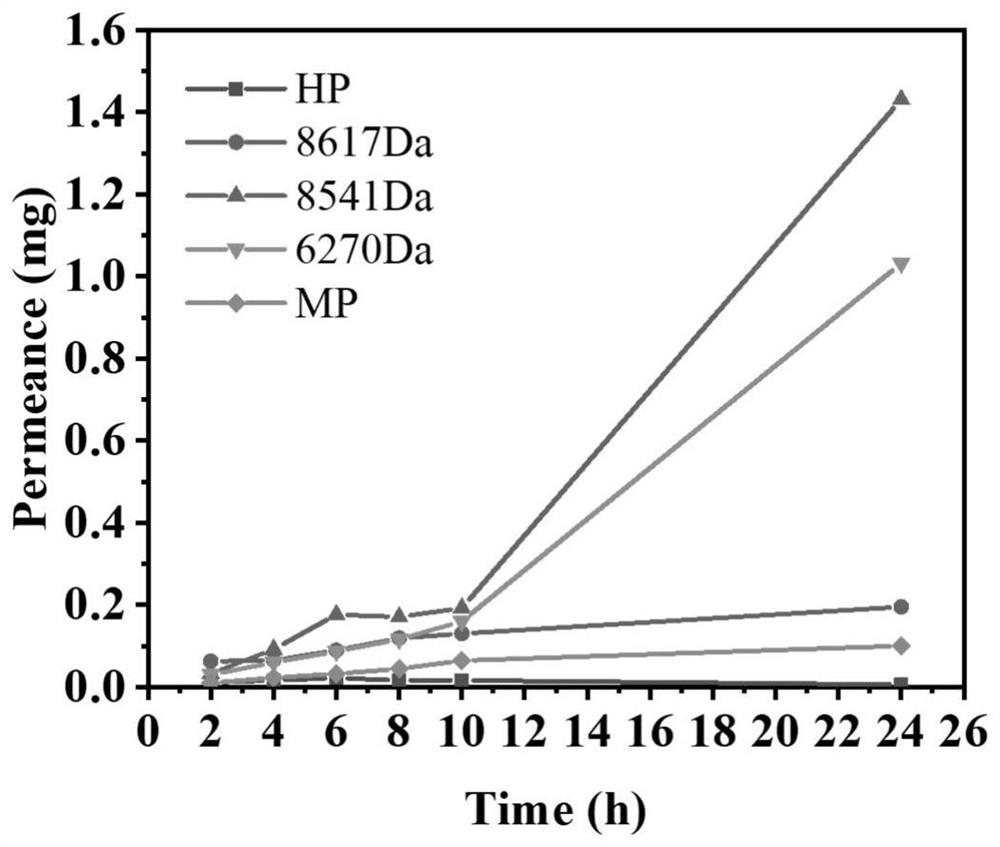

Image

Examples

Embodiment 1

[0037] A kind of small molecule pectin preparation method provided by the invention comprises the following steps successively:

[0038] (1) Dissolving pectin

[0039]Weigh 5g of high molecular weight pectin and dissolve it in 100ml of deionized water under stirring conditions, the stirring speed is 800rpm, the temperature is 60°C, and the stirring time is 60min.

[0040] (2) Enzymatic hydrolysis of pectin

[0041] After the polymer pectin is completely dissolved, pectinase whose mass is 6% of the dry weight of the polymer pectin is added, the enzymolysis temperature is 30° C., and the enzymolysis time is 60 min.

[0042] (3) Pectin oxidation

[0043] After enzymatic hydrolysis of pectin, 30% hydrogen peroxide was added immediately to make the final concentration 3%, the oxidation temperature was 30°C, and the oxidation time was 30 minutes.

[0044] (4) Rotating ceramic membrane filtration and concentration:

[0045] The small molecule pectin solution is filtered and conce...

Embodiment 2

[0050] A kind of small molecule pectin preparation method provided by the invention comprises the following steps successively:

[0051] (1) Dissolving pectin

[0052] Weigh 5g of high molecular weight pectin and dissolve it in 100ml of deionized water under stirring conditions, the stirring speed is 800rpm, the temperature is 60°C, and the stirring time is 60min.

[0053] (2) Enzymatic hydrolysis of pectin

[0054] After the polymer pectin is completely dissolved, pectinase whose mass is 7% of the dry weight of the polymer pectin is added, the enzymolysis temperature is 30° C., and the enzymolysis time is 60 minutes.

[0055] (3) Pectin oxidation

[0056] After enzymatic hydrolysis of pectin, 30% hydrogen peroxide was added immediately to make the final concentration 3%, the oxidation temperature was 30°C, and the oxidation time was 30 minutes.

[0057] (4) Rotating ceramic membrane filtration and concentration:

[0058] The small molecule pectin solution is filtered and ...

Embodiment 3

[0063] A kind of small molecule pectin preparation method provided by the invention comprises the following steps successively:

[0064] (1) Dissolving pectin

[0065] Weigh 5g of high molecular weight pectin and dissolve it in 100ml of deionized water under stirring conditions, the stirring speed is 800rpm, the temperature is 60°C, and the stirring time is 60min.

[0066] (2) Enzymatic hydrolysis of pectin

[0067] After the polymer pectin is completely dissolved, pectinase whose mass is 6% of the dry weight of the polymer pectin is added, the enzymolysis temperature is 30° C., and the enzymolysis time is 60 min.

[0068] (3) Pectin oxidation

[0069] After enzymatic hydrolysis of pectin, hydrogen peroxide was added immediately to make the final concentration 2%, the oxidation temperature was 30°C, and the oxidation time was 30 minutes.

[0070] (4) Rotating ceramic membrane filtration and concentration:

[0071] The small molecule pectin solution is filtered and concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com