Low-freezing-point coating material for road, and preparation method thereof

A coating material, freezing point technology, applied in coatings, asphalt coatings, climate change adaptation, etc., to achieve the effects of shortening drying time, good workability, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Preparation of temperature-adjusted modified masterbatch

[0059] Table 3 Modified masterbatch material ratio and parameter control

[0060]

[0061] Material Description:

[0062] Oleic acid: molecular weight 282.46, melting point 13-14°C;

[0063] Palmitoleic acid: molecular weight 254.41, melting point 0.5°C;

[0064] Soybean oleic acid: 280≤molecular weight≤284, melting point 15℃.

[0065] 【Preparation】

[0066] Add the main solvent II and anti-penetration agent in the formula amount into a small reaction kettle, stir at 50°C for 20 minutes to dissolve completely, then add silane coupling agent and temperature regulating agent in turn, maintain the temperature and continue stirring for 40 minutes, and naturally drop to After room temperature, ultrasonically treat for a certain period of time to obtain activated temperature-adjusted modified masterbatches, which are respectively recorded as masterbatch 1, masterbatch 2, masterbatch 3, masterbatch 4,...

Embodiment 2

[0067] Example 2: Preparation of low freezing point coating materials for roads.

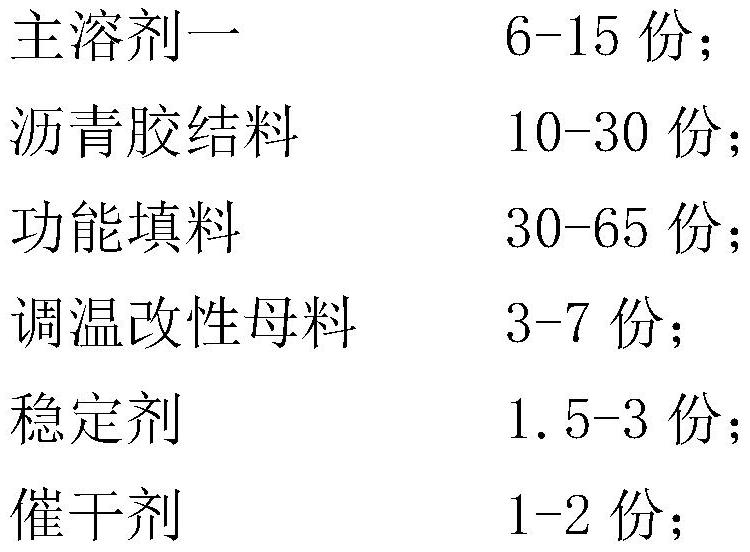

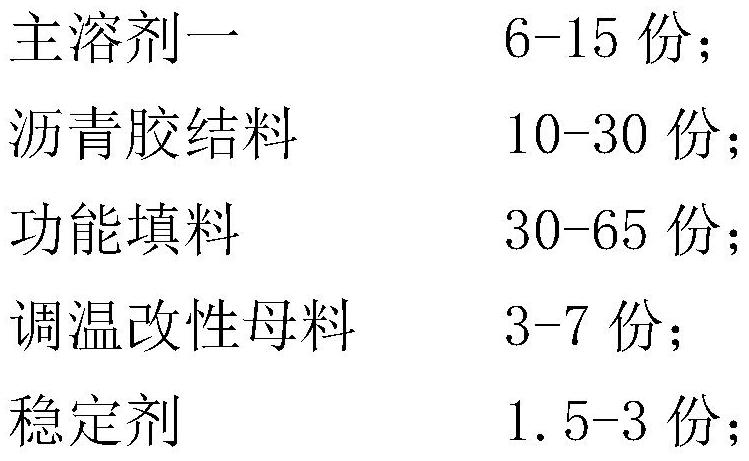

[0068] Table 4 Material ratio of coating materials

[0069]

[0070] Material Description:

[0071] Qingchuan Rock Asphalt: Penetration 3 (0.1mm) at 25°C, softening point 220°C;

[0072] 50# asphalt: at 25°C, the penetration is 45 (0.1mm), and the softening point is 67°C;

[0073] 40# asphalt: at 25°C, the penetration is 38 (0.1mm), and the softening point is 70°C;

[0074] 30# asphalt: at 25°C, the penetration is 28 (0.1mm), and the softening point is 72°C.

[0075] 【Preparation】

[0076] A1. Heating the asphalt binder to 135°C, and then cooling to maintain a fluid and transportable state to obtain component A;

[0077] A2. Mix the main solvent 1 with the temperature-adjusted modified masterbatch at a temperature of 50°C and stir evenly to obtain component B;

[0078] A3. Slowly add component A to the main mixer of component B and mix, then add stabilizer, drier, and functional filler ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com