Synthesis method of ion conjugated polyelectrolyte material and application of ion conjugated polyelectrolyte material in perovskite solar cell

A technology of conjugated polyelectrolyte and perovskite, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problem of low power conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0022] Synthesis of fluorenyl ion conjugate polymer solution FF-BOC:

[0023] The reaction equation is as follows:

[0024]

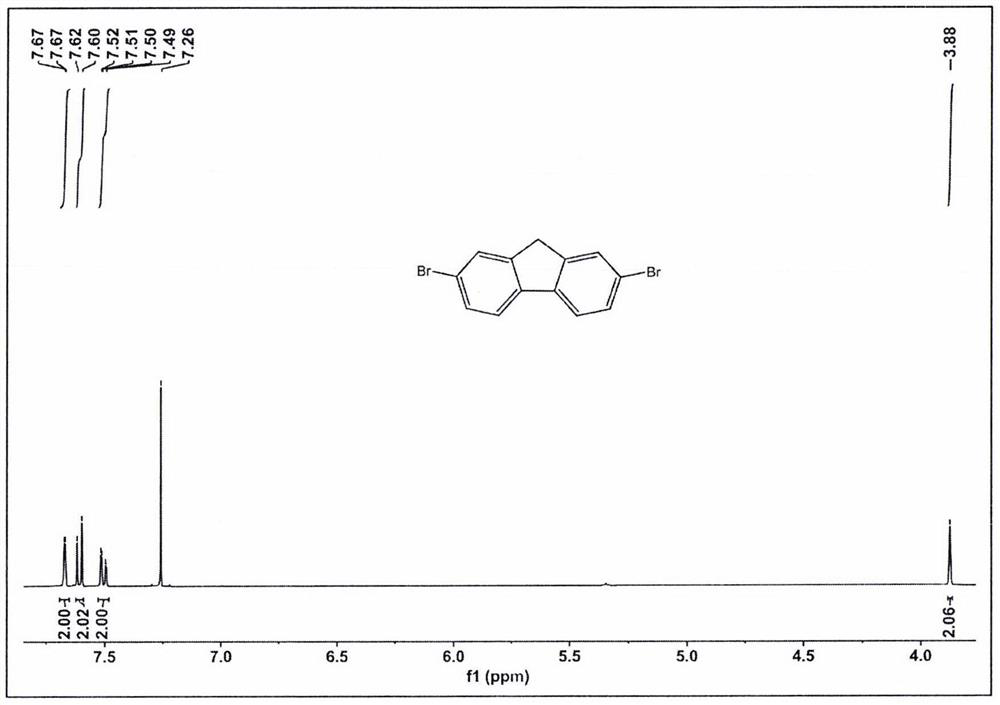

[0025] Compound 1 synthesis

[0026] 10 g of hydrazine and 0.15 g of FeCl3 were dissolved in 50 ml of chloroform, and the solution temperature was reduced to 0 ° C, then add 6.46 mL of BR2; then slowly increased to room temperature after the dropwise addition was completed, and stirred for 2 h. Post treatment: neutralized with a saturated sodium hydrogen sulfite solution and the resulting mixture was extracted three times with 20 ml of dichloromethane. The combined organic phase was dried over anhydrous sodium sulfate, and the solvent was evaporated under reduced pressure. No further purification was required, and the white solid compound was obtained, and the yield was 95%. 1 H NMR (400MHz, CDCL 3 Δ (PPM): 7.67 (S, 2H), 7.61 (D, 2H), 7.50 (D, 2H), 3.88 (S, 2H).

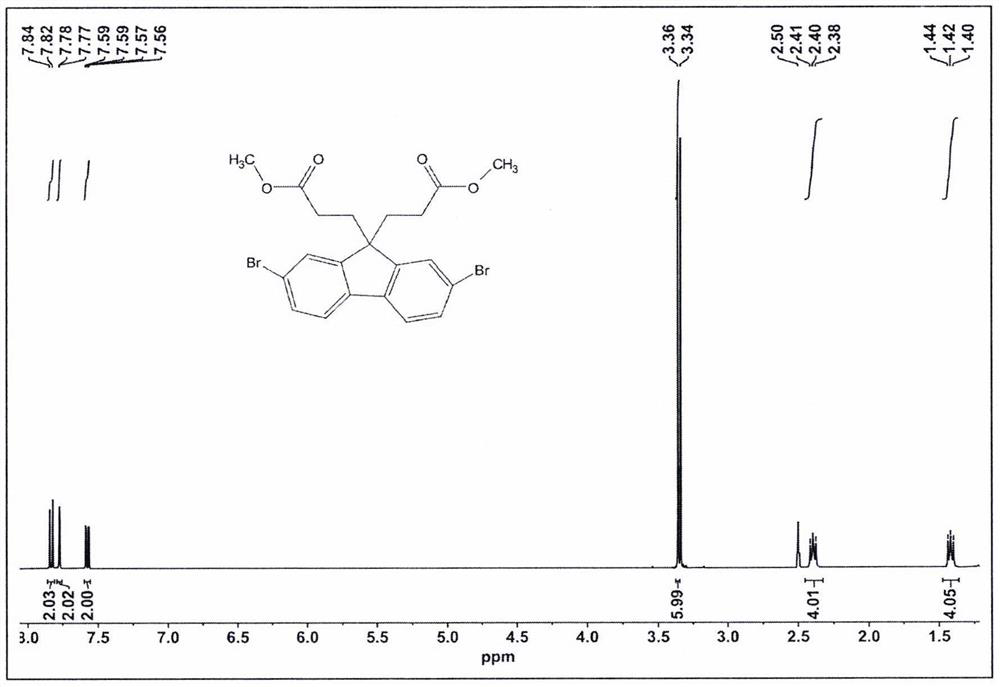

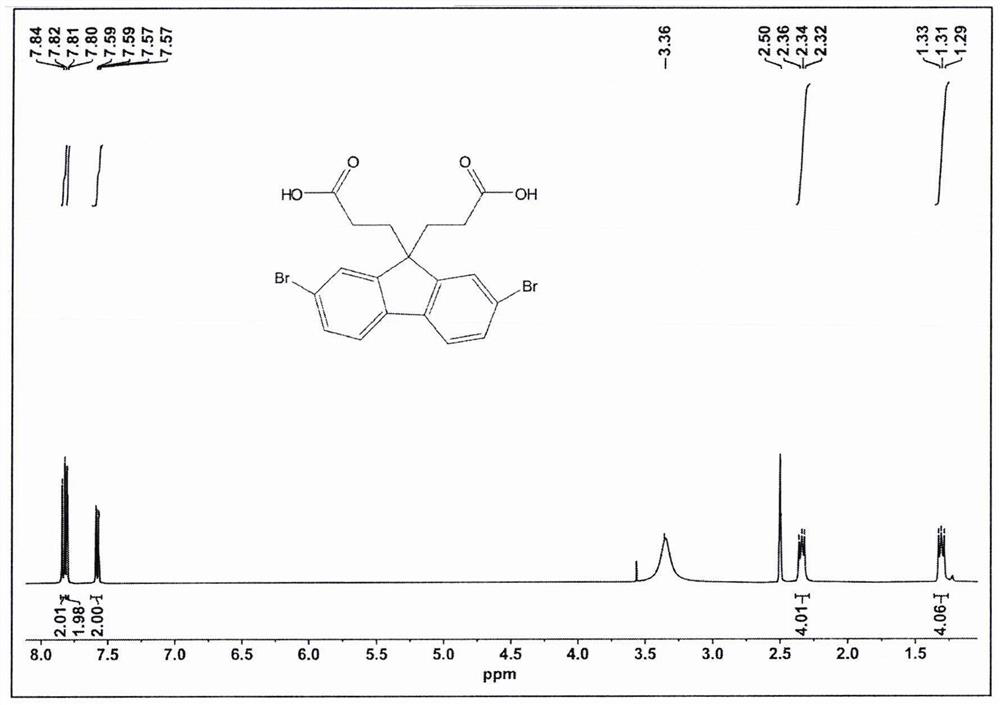

[0027] Compound 2 synthesis

[0028] 6 g of compound 1,5.16 g of methyl acrylate, 600 mg tet...

Embodiment example 2

[0040] Preparation and characterization of perovskite solar cells:

[0041] (1) Etch of 1.5 cm x 1.5 cm ITO substrate using dilute hydrochloric acid and zinc powder, after rubbing with cotton balls, rinsed with water, deionized water, acetone, isopropanol, 15min, washed, blow it with nitrogen Dry, UV-O 3 Among them for 20 min.

[0042] (2) Standard device ITO / SNO 2 / Mapbi 3 Preparation of / Spiro-OmetAd / Au:

[0043] First SNO first 2 Spin coated to the treated ITO substrate, annealed 10-40 min under the conditions of 100-150 ° C; a good PBI 2 Mixed solution with MAI DMSO / DMF to Sno 2 The film is annealed at 80-130 ° C for 10-20 min under the conditions of 80-130 ° C; finally Spiro-Ometad at 4000 rpm, 30s, and the Au film is 80 nm.

[0044] (3) FF-BOC as a battery ITO / SNO for interface transport materials 2 / Mapbi 3 / FF-BOC / Spiro-Omet / Au Preparation:

[0045] The steps are the same as above (1) and (2), and the FF-BoC is introduced into the interface between the calciu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com