Anti-nodulation tundish ventilation upper nozzle

A tundish and anti-nodulation technology, which is applied in the direction of casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to adapt to changes in steel mill technology and smelting steel types, poor anti-oxidation and anti-nodulation performance, and easy Problems such as nodules and clogging occur, to achieve excellent product cost performance, ensure permeability and stability, and improve the effect of easy nodulation and clogging

Inactive Publication Date: 2021-10-01

BAOSHAN IRON & STEEL CO LTD

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

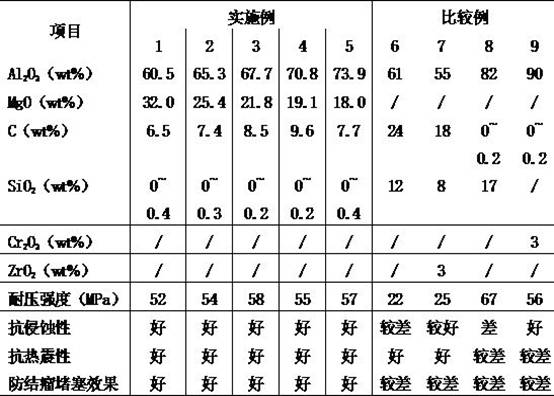

At present, there are many types of materials that can be used for the ventilating upper nozzle of the tundish, mainly Al of corundum mullite. 2 o 3 -SiO 2 quality, chrome corundum Al 2 o 3 -Cr 2 o 3 Quality, Al 2 o 3 -C quality, Al 2 o 3 -ZrO 2 -C quality, etc., among them, corundum mullite contains SiO 2 The thermal shock resistance is very good, but the corrosion resistance is poor, and it is easy to nodulate and block after melting, while corundum and chrome corundum contain Al 2 o 3 It has good corrosion resistance, high strength, and erosion resistance, but poor thermal shock resistance, prone to cracks, and nodules on the inner wall

Tundish venting upper nozzles can also be divided into two categories: carbon-containing and carbon-free. The C content of carbon-containing upper nozzles is generally at least 18%. High carbon content leads to lower strength, and is not resistant to erosion, oxidation resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

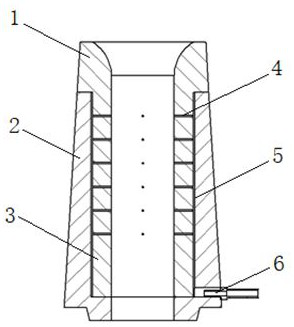

The invention relates to an anti-nodulation tundish ventilation upper nozzle which comprises a bowl part (1), an outer layer body (2), an inner layer ventilation body (3), straight through holes (4), an air chamber slit (5) and an air inlet argon blowing pipe (6), and external argon enters an inner cavity of the upper nozzle through the air inlet argon blowing pipe, the air chamber slit and the straight through holes in sequence. The bowl part and the inner layer ventilation body are made of an Al2O3-MgO-C material, and the chemical components of the Al2O3-MgO-C material comprise, by weight, 60%-74% of Al2O3, 18%-32% of MgO, 6%-10% of C and the balance trace impurities. The Al2O3-MgO-C material is further additionally provided with an antioxidant and a phenolic resin binding agent. The anti-nodulation tundish ventilation upper nozzle can provide excellent thermal shock resistance, erosion resistance and oxidation resistance, has excellent comprehensive performance, can improve the problem that the upper nozzle is easy to nodule and block, and has reasonable cost and stable quality.

Description

technical field [0001] The invention relates to the technical field of steelmaking and continuous casting, in particular to an anti-nodulation tundish venting upper nozzle. Background technique [0002] As an important link in the continuous casting system, the tundish should not only stabilize the quality of the molten steel after secondary treatment, but also promote the floating and separation of inclusions in the molten steel, uniform composition and temperature, improve the quality of the molten steel and stabilize the casting operation. The upper nozzle of the tundish is an important part in continuous casting production. The bowl of the upper nozzle cooperates with the stopper rod head to control the flow of molten steel and affect the liquid level of the tundish. However, in the continuous casting process, the inner wall and bowl of the upper nozzle often have inclusions in molten steel adhering to it, causing nodules or blockage of the upper nozzle, which seriously ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22D41/54B22D41/58

CPCB22D41/54B22D41/58B22D41/50C04B35/66

Inventor 甘菲芳高华陈兆平蒋晓放徐国栋梅峰

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com