Non-woven fabric liquid preparation system and method capable of realizing automatic liquid preparation

A technology for automatic liquid dispensing and liquid dispensing system, which is applied in chemical instruments and methods, shaking/oscillating/vibrating mixers, mixers with rotary stirring devices, etc. problems such as disappearance, to achieve the effect of improving the quality of the final product and the quality of the preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Non-woven fabric dispensing method that can realize automatic dispensing:

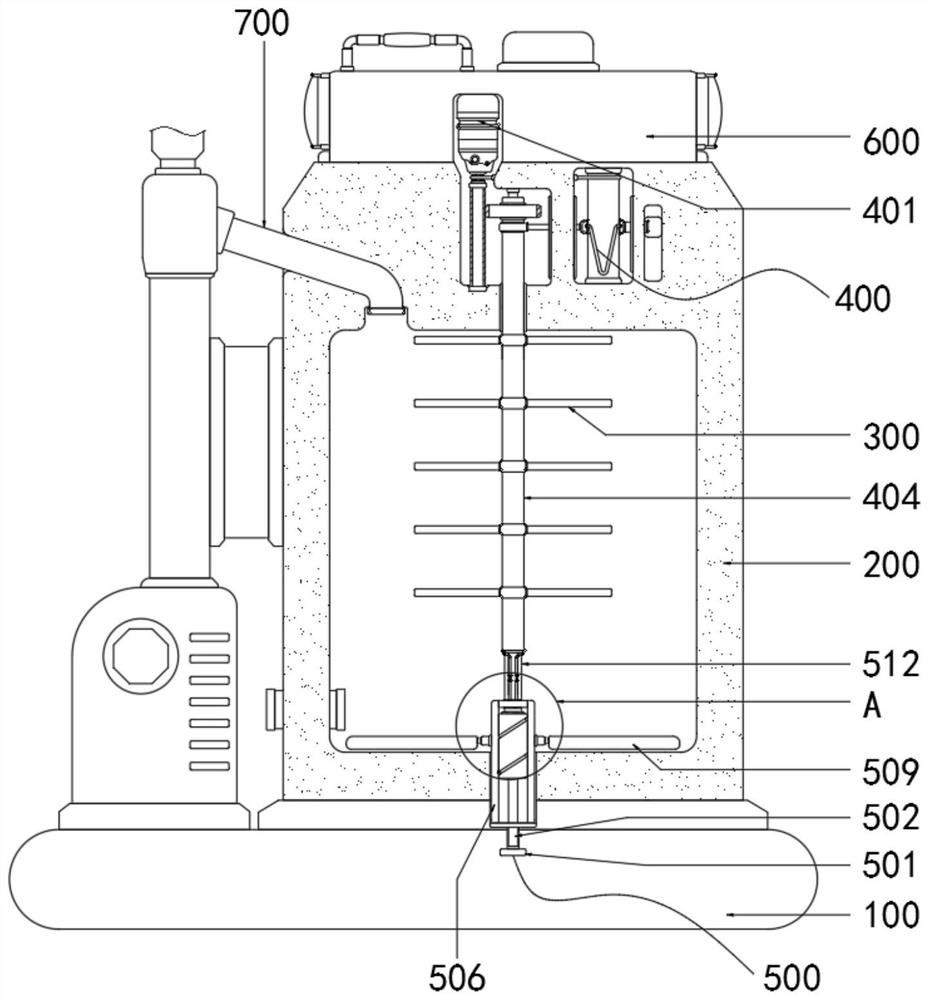

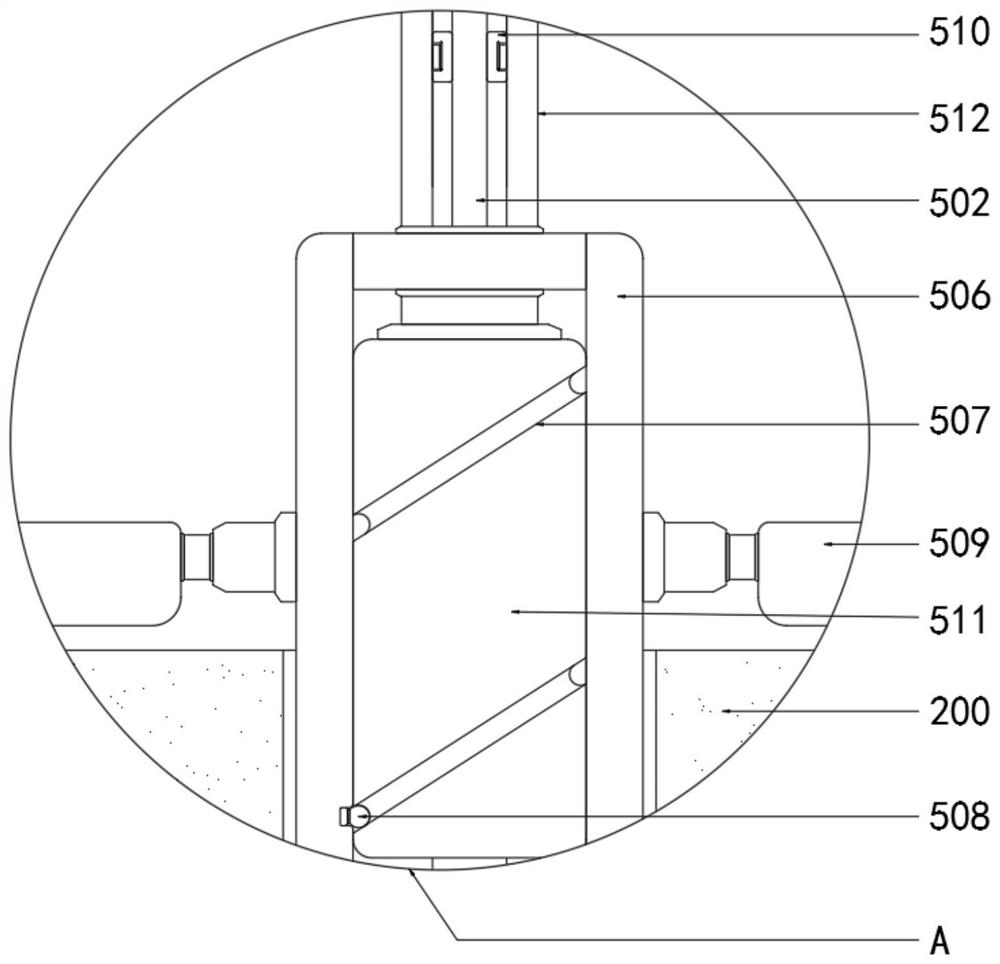

[0043] S1: Add the mixed liquid raw material from the feed pipe 700 into the box 200, and then start the driving motor 401;

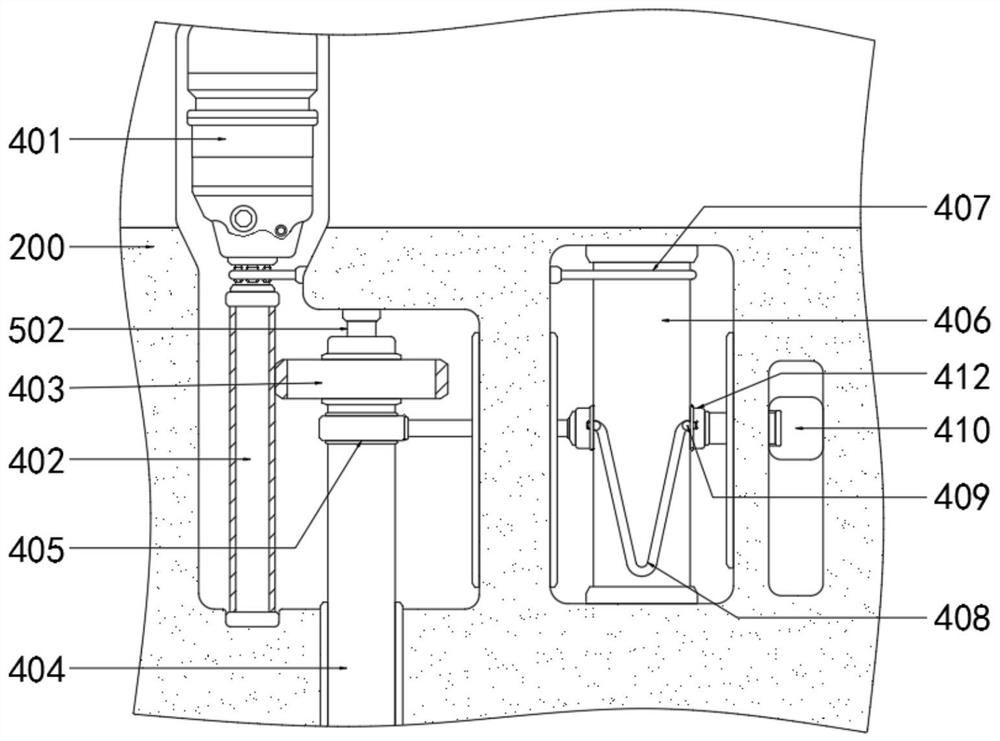

[0044] S2: The driving motor 401 is running at a speed of 500r / min. The driving motor 401 rotates with the transmission gear 403 through the gear column 402, and the transmission gear 403 rotates with the stirring rod 300 through the rotating sleeve 404, thereby stirring the mixed liquid;

[0045] S3: Simultaneously drive the motor 401 to rotate with the rotating column 406 through the transmission belt 407, the rotating column 406 moves up and down with the movable sleeve 412 through the serpentine groove 408 and the first rolling ball 409, the rotating column 406 rotates one circle and the movable sleeve 412 reciprocates twice;

[0046] S4: The movable sleeve 412 reciprocates up and down with the rotating sleeve 404 through the connecting sleeve 405;

[0047] S5: The ...

Embodiment 2

[0051] Non-woven fabric dispensing method that can realize automatic dispensing:

[0052] S1: Add the mixed liquid raw material from the feed pipe 700 into the box 200, and then start the driving motor 401;

[0053] S2: The drive motor 401 is running at a speed of 550r / min. The drive motor 401 rotates with the transmission gear 403 through the gear column 402, and the transmission gear 403 rotates with the stirring rod 300 through the rotary sleeve 404, thereby stirring the mixed liquid;

[0054] S3: Simultaneously drive the motor 401 to rotate with the rotating column 406 through the transmission belt 407, the rotating column 406 moves up and down with the movable sleeve 412 through the serpentine groove 408 and the first rolling ball 409, the rotating column 406 rotates one circle and the movable sleeve 412 reciprocates twice;

[0055] S4: The movable sleeve 412 reciprocates up and down with the rotating sleeve 404 through the connecting sleeve 405;

[0056] S5: The rotary...

Embodiment 3

[0060] Non-woven fabric dispensing method that can realize automatic dispensing:

[0061] S1: Add the mixed liquid raw material from the feed pipe 700 into the box 200, and then start the driving motor 401;

[0062] S2: The driving motor 401 is running at a speed of 600r / min. The driving motor 401 rotates with the transmission gear 403 through the gear column 402, and the transmission gear 403 rotates with the stirring rod 300 through the rotary sleeve 404, thereby stirring the mixed liquid;

[0063] S3: Simultaneously drive the motor 401 to rotate with the rotating column 406 through the transmission belt 407, the rotating column 406 moves up and down with the movable sleeve 412 through the serpentine groove 408 and the first rolling ball 409, the rotating column 406 rotates one circle and the movable sleeve 412 reciprocates twice;

[0064] S4: The movable sleeve 412 reciprocates up and down with the rotating sleeve 404 through the connecting sleeve 405;

[0065] S5: The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com