Sensor element

A sensor element and pump unit technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as the deterioration of measurement accuracy, and achieve the effect of suppressing deterioration over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]

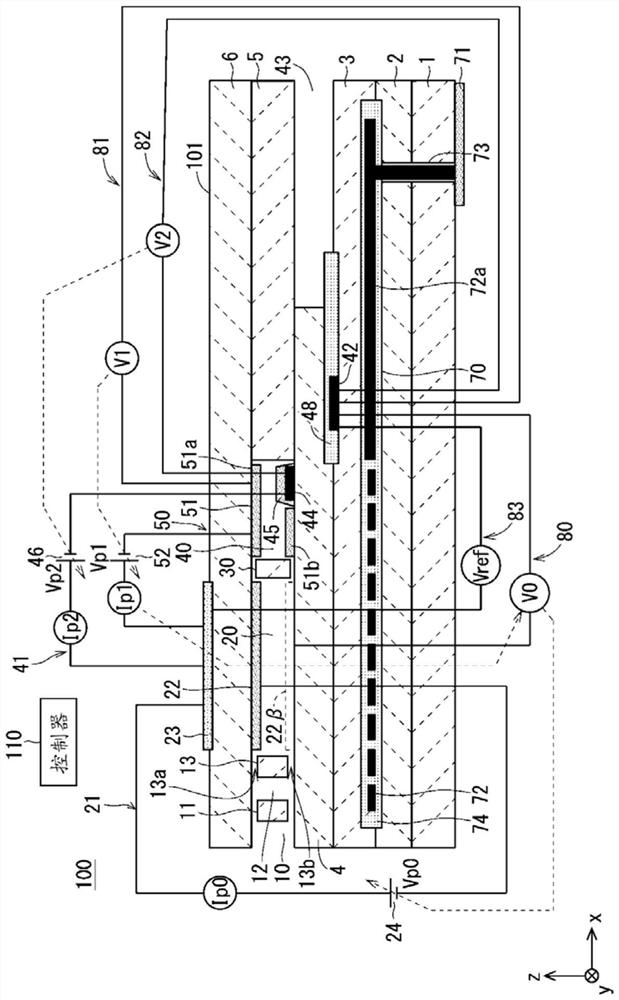

[0032] First, the schematic configuration of the gas sensor 100 including the sensor element 101 according to the present embodiment will be described. In the present embodiment, the gas sensor 100 is a limiting current type NOx sensor that monitors NOx using the sensor element 101 and measures its concentration. In addition, the gas sensor 100 further includes a controller 110 that controls the operation of each part and determines the NOx concentration based on the NOx current flowing through the sensor element 101 .

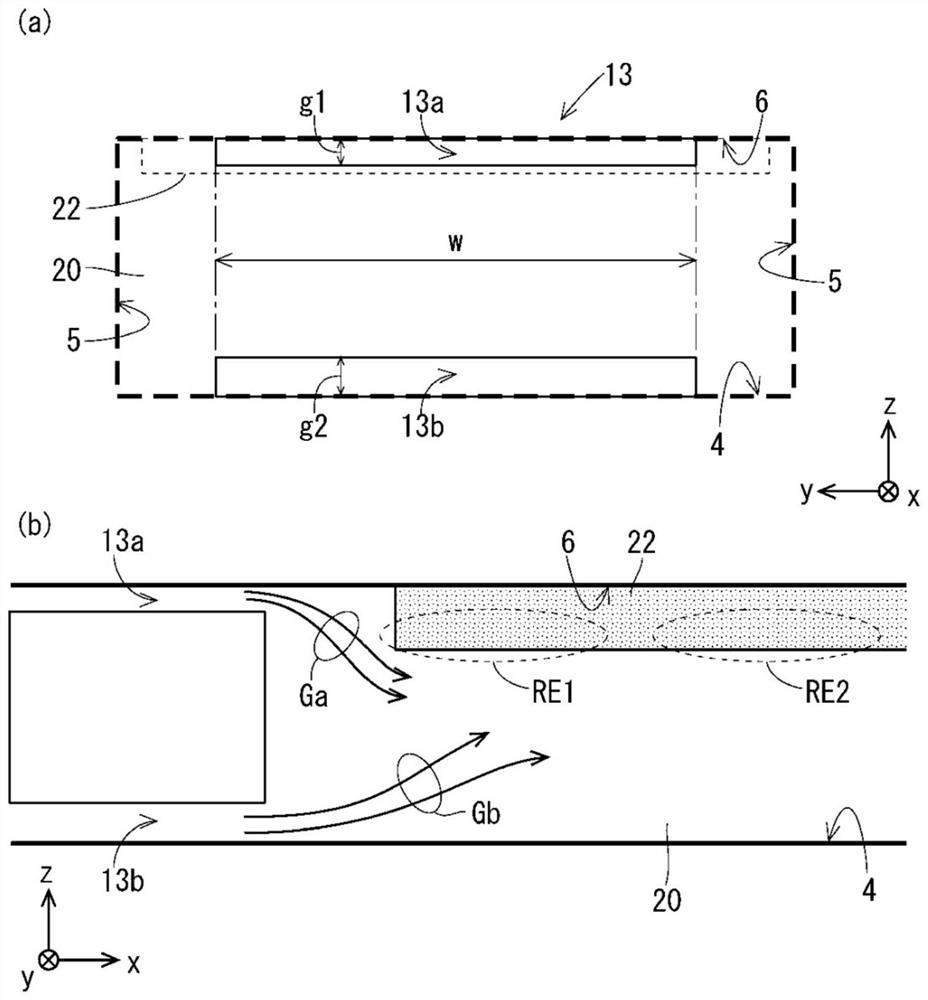

[0033] figure 1 It is a diagram schematically showing an example of the structure of the gas sensor 100 including a vertical cross-sectional view along the longitudinal direction of the sensor element 101 . should be explained, figure 1 marked: the xyz coordinates of the right-handed system with the length direction of the sensor element 101 as the x-axis direction, the width direction as the y-axis direction, and the thickness direction as the z-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com