Gas Adsorbents and Gas Adsorbent Sheets and Air Filters

A technology of gas adsorbents and flakes, which is applied in membrane filters, gas treatment, and other chemical processes. Effect of aldehyde removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] [Measurement methods]

[0070] (1) The loading amount of water-soluble acid hydrazide compound and the loading amount of the compound having a mercapto group in the functional group (parts by mass):

[0071] The difference between the mass of the gas adsorbent after impregnating and drying a liquid in which a water-soluble acid hydrazide compound and a compound having a mercapto group in a functional group is impregnated and dried, and the mass of the inorganic porous medium before impregnation and drying The difference was used to calculate the total loading amount, and the total loading amount was multiplied by the feed amount ratio of each component, converted into the loading amount with respect to the entire gas adsorbent, and then calculated.

[0072] (2) pH (hydrogen ion index) of the gas adsorbent:

[0073] 100 g of pure water at a temperature of 25° C. was impregnated with 5% by mass of the gas adsorbent, stirred gently, and left to stand for 10 minutes. The p...

Embodiment 2

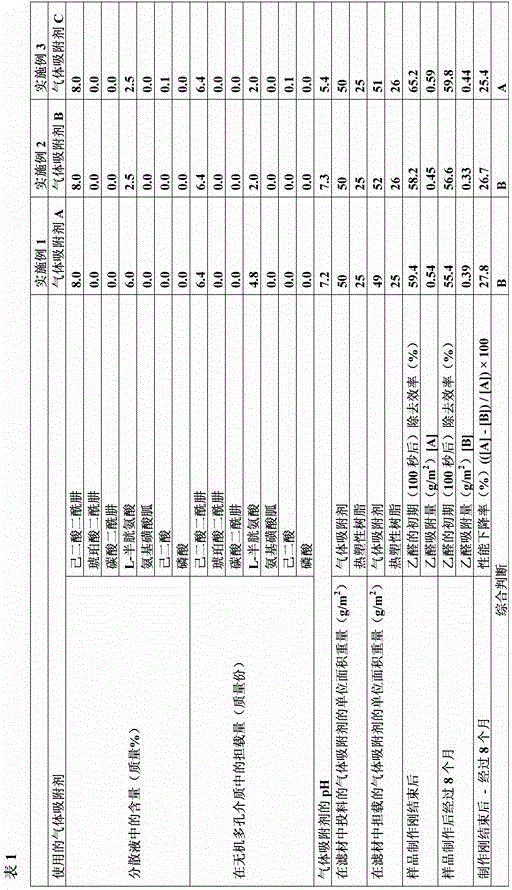

[0204] As the gas absorbent, except for using the gas adsorbent B prepared above, the same air-permeable sheet and thermal fusion resin as in Example 1 were used, and the gas adsorbent sheet B was produced by the same manufacturing method as in Example 1. . The results are shown in Table 1.

Embodiment 3

[0206] As the gas absorbent, except for using the gas adsorbent C produced above, the gas-adsorbing sheet C was produced by the same manufacturing method as in Example 1, using the same air-permeable sheet and thermal fusion resin as in Example 1. . The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com