System for testing melting point of magnesium metal

A technology of magnesium metal and melting point, applied in the field of systems for testing the melting point of magnesium metal, can solve problems such as inability to monitor magnesium metal in real time, inability to establish real-time connection between temperature and weight of magnesium metal, and poor control of environmental variables, so as to facilitate comparison and correction. Experimental data, easy cleaning, and the effect of ensuring credibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

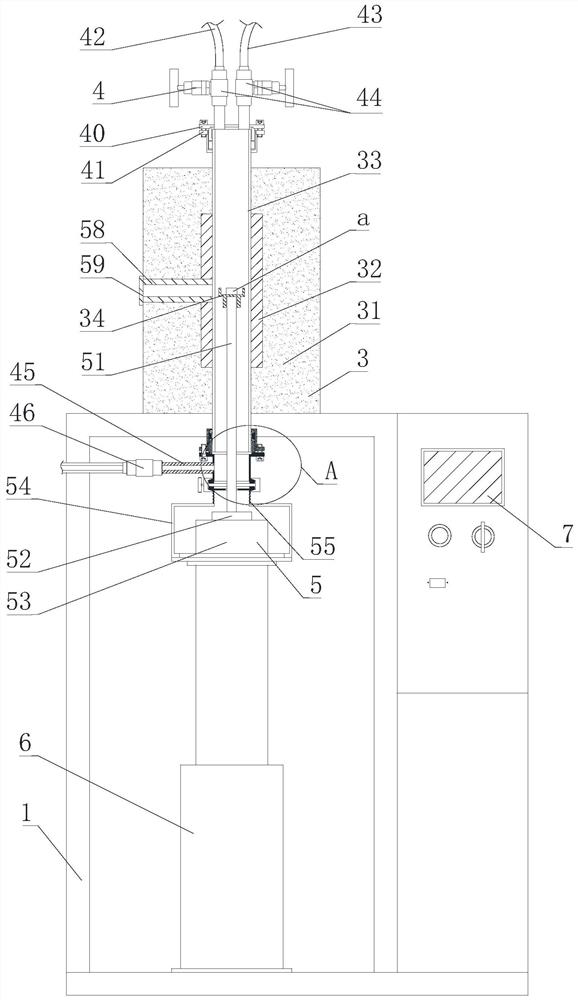

[0027] Attached below Figure 1-3 The present invention is further described with embodiment:

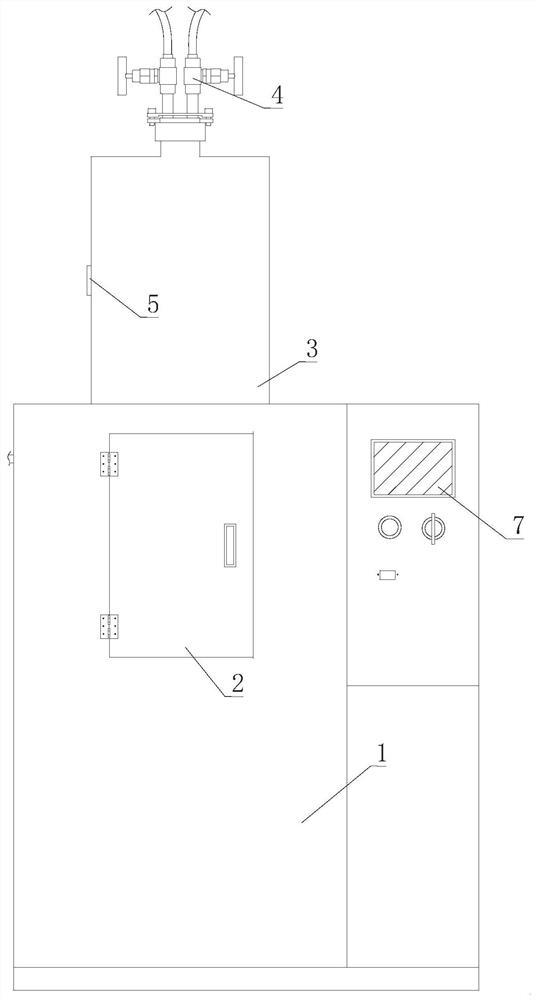

[0028] A system for testing the melting point of magnesium metal, comprising a hollow box 1 and a box door 2 embedded in the front wall of the box 1, a heating mechanism 3 is arranged on the top wall of the box 1, and a gas heating mechanism is arranged above the heating mechanism. A circulation mechanism 4, a weighing mechanism 5 is provided in the inner cavity of the box body 1;

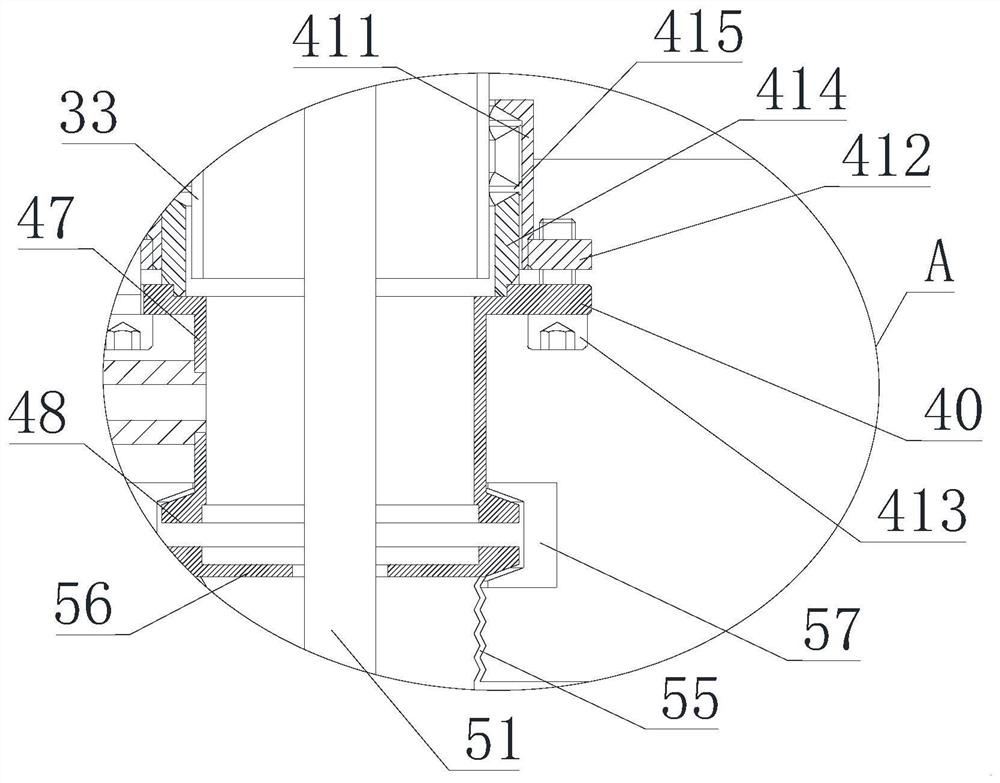

[0029] In this example, if figure 1 and 2 As shown, the heating mechanism 3 includes a heating furnace wall 31 vertically installed on the top wall of the box body 1, and a cylindrical quartz furnace cavity 33 is vertically penetrated in the heating furnace wall 31, and the quartz furnace cavity 33 A heating tube 32 is set on the outer side of the annular side wall, and a quartz crucible 34 is arranged in the inner cavity of the quartz furnace cavity 33 corresponding to the middle of the heating tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com