Mems pressure sensor based on frequency detection principle and preparation method

A pressure sensor and principle technology, which is applied in the direction of fluid pressure measurement using inductance changes, fluid pressure measurement using capacitance changes, and measuring force, etc., can solve the problems of complex preparation of piezoelectric materials, difficult standard process compatibility, and low resolution ability. , to achieve the effect of low price, improving device performance and reducing chip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, those skilled in the art are in the range of the protected by the present invention without creative labor premistence.

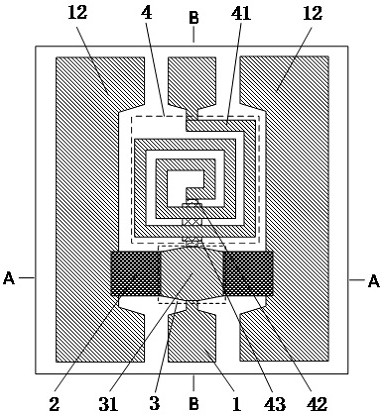

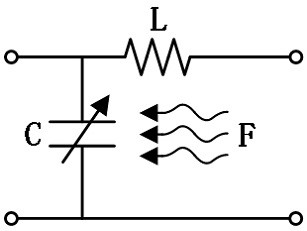

[0032] The present embodiment provides a MEMS pressure sensor is based on the principle of detecting a frequency change, such as Figure 1 ~ 3 , On the dielectric substrate 13 is provided with a buffer layer 132, CPW transmission line, planar spiral inductor 4, MEMS variable parallel plate capacitor 3, MEMS film 2, the recess 131 and the insulating dielectric layer 43.

[0033] The CPW transmission line comprises an intermediate portion 13 of the CPW substrate two CPW signal line 1 and ground 1 located on bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com