Production method of dimethyl sebacate

A technology of dimethyl sebacate and a production method, which is applied in the separation/purification of carboxylate, the preparation of carboxylate, chemical instruments and methods, etc., can solve the problems of being difficult to be distilled off, reducing methanol concentration, and consuming heat energy. , to achieve the effect of improving product purity, reducing product acid value and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

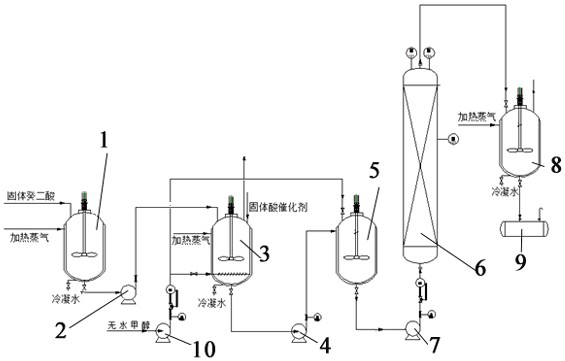

Image

Examples

Embodiment 1

[0024] 1) First, put the solid sebacic acid into the melting kettle 1, and heat it by passing heating steam into the jacket of the melting kettle, and heat it to 140°C to completely melt the solid sebacic acid; the melting time is 60 minutes, and the product is measured The acid value is 554.5mgKOH / g;

[0025] 2) The melted sebacic acid is pumped from the lower part of the melting tank 1 into the primary esterification tank 3 through the sebacic acid feed pump 2, and a strong acidic ion exchange resin is added. 12.5wt%, using the methanol feed pump 10 to add the liquid methanol flow into the primary esterification tank 3, so that the primary esterification reaction of sebacic acid and methanol occurs, and the flow rate of methanol is 0.007 mL / (g sebacic acid min ), reacted at 140°C for 120min, the acid value of the primary esterified product was measured to be 15.2gmgKOH / g, and the esterification rate was 97.3%;

[0026] 3) Use the first infusion pump 4 to pump the primary es...

Embodiment 2

[0030] 1) First, put the solid sebacic acid into the melting kettle 1, and heat it by passing heating steam into the jacket of the melting kettle, and heat it to 130°C to completely melt the solid sebacic acid; the melting time is 70 minutes, and the product is measured The acid value is 554.5mgKOH / g;

[0031] 2) The melted sebacic acid is pumped from the lower part of the melting kettle 1 into the primary esterification kettle 3 through the sebacic acid feed pump 2, and sulfonated carbon is added. The amount of sulfonated carbon is 3wt% of the raw material mass. The methanol feed pump 10 feeds the liquid methanol flow into the primary esterification tank 3 to cause the primary esterification reaction between sebacic acid and methanol. The methanol flow rate is 0.02 mL / (g sebacic acid min), at 150°C After reacting for 60 minutes, the acid value of the primary esterified product was measured to be 18.1 mgKOH / g, and the esterification rate was 96.7%;

[0032] 3) Use the first i...

Embodiment 3

[0036] 1) First put the solid sebacic acid into the melting kettle 1, and heat it by passing heating steam into the jacket of the melting kettle, and heat it to 150°C to completely melt the solid sebacic acid; the melting time is 50 minutes, and the product The acid value is 554.5mgKOH / g;

[0037] 2) The melted sebacic acid is pumped from the lower part of the melting kettle 1 into the primary esterification kettle 3 through the sebacic acid feed pump 2, and a strong acidic ion exchange resin is added. 6.25wt%, using the methanol feed pump 10 to add the liquid methanol flow to the primary esterification tank 3, so that the primary esterification reaction of sebacic acid and methanol occurs, and the flow rate of methanol is 0.015 mL / (g sebacic acid min ), reacted at 130°C for 100min, the acid value of the primary esterified product was measured to be 17.4gmgKOH / g, and the esterification rate was 96.8%;

[0038] 3) Use the first infusion pump 4 to pump the primary esterified pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com