Device for simulating flowing and heat transfer characteristics of water-oil mixture in regenerative cooling channel

A simulation device, regenerative cooling technology, applied in the direction of flow characteristics, measurement devices, material thermal development, etc., can solve the problems of unclear emulsifier characteristics, restricted application range, limited storage time of emulsified fuel, etc., to achieve long working time and expand The effect of strong ability and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

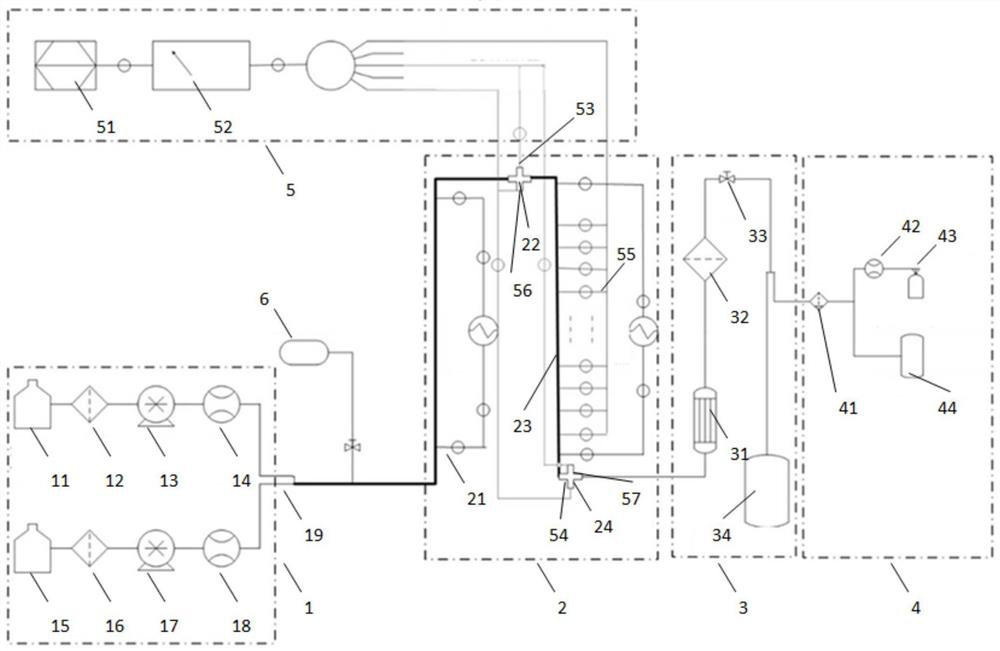

[0058] During the experiment, two constant-flow pumps 13 and 17 pumped kerosene and water from storage tanks 11 and 15 through filters 12 and 16 at a set volume flow respectively, and mixed them at the tee 19 at the outlet of water-oil supply system 1 . During this process the flow meters 14, 18 measure the actual flow of the two fluids respectively.

[0059] The mixed liquid is heated in a two-stage heating system 2 . Wherein 21 is a preheating section, which promotes the mixing of kerosene and water in the pipeline through preheating. The temperature sensor and the pressure sensor installed at the 22 places of the four-way one measure the temperature and pressure of the preheated mixed fluid. The preheated mixed fluid is heated in the secondary heating section 23 to the temperature required for the experiment. The heated fluid is subjected to temperature and pressure measurement for the second time at Sitong 2 21 .

[0060] The mixed fluid is cooled and recovered in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com