A kind of nylon weft elastic pipeline cloth anti-velvet technology

A process and anti-down technology, which is applied in textiles and papermaking, dyeing, dry-cleaning fiber products, etc., can solve the problems of gap enlargement and down leakage, and achieve excellent anti-down effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

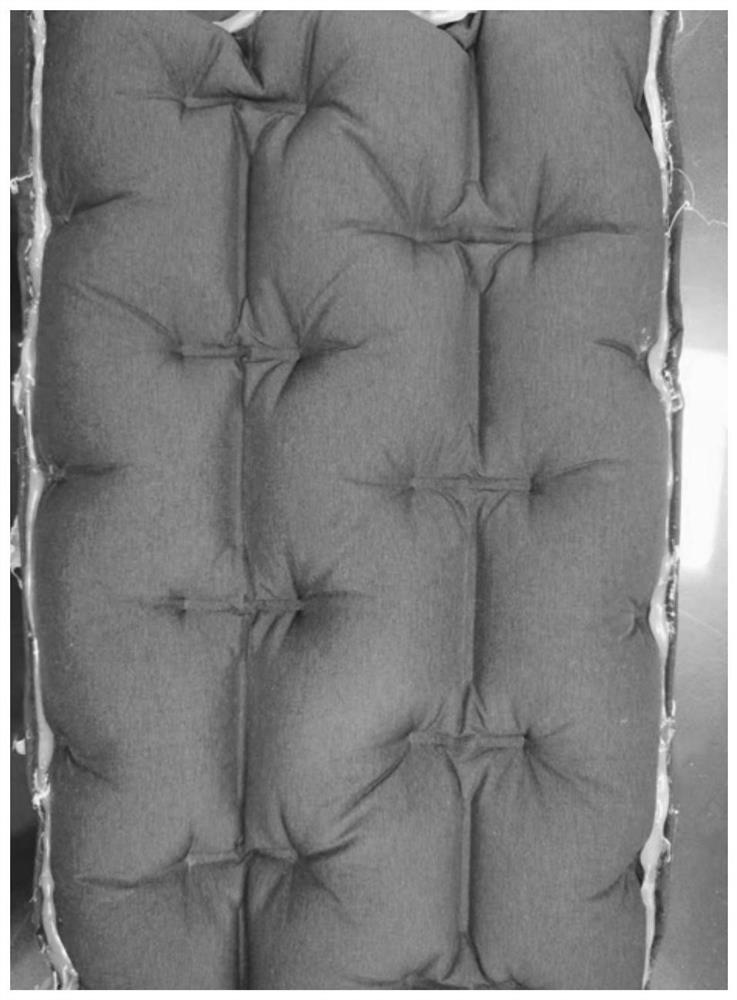

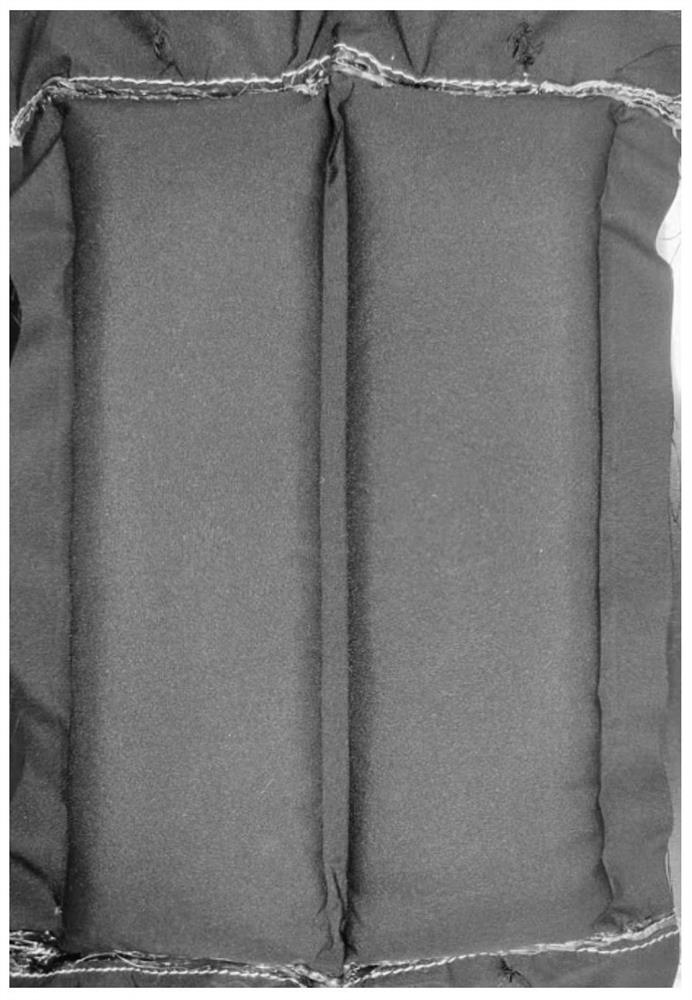

Image

Examples

Embodiment 1

[0024] A kind of nylon weft elastic pipeline cloth anti-velvet technology

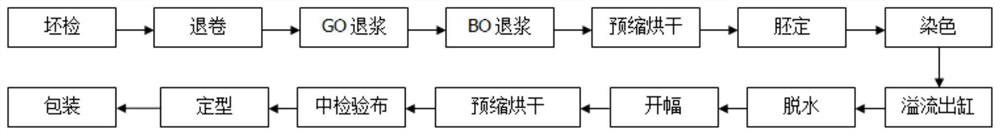

[0025] The velvet-proof process of nylon weft elastic pipeline includes the following steps in sequence: blank inspection → unwinding → GO desizing → BO desizing → pre-shrinking drying → blank setting → dyeing → overflow cylinder → dehydration → opening → pre-shrinking drying Drying→Intermediate Inspection Cloth→Styling→Packing.

[0026] The specific parameters of the anti-velvet process of the present embodiment are shown in Table 1:

[0027] Table 1

[0028]

[0029]

[0030]

Embodiment 2

[0032] A kind of nylon weft elastic pipeline cloth anti-velvet technology

[0033] The velvet-proof process of nylon weft elastic pipeline includes the following steps in sequence: blank inspection → unwinding → GO desizing → BO desizing → pre-shrinking drying → blank setting → dyeing → overflow cylinder → dehydration → opening → pre-shrinking drying Drying→Intermediate Inspection Cloth→Styling→Packing.

[0034] The specific parameters of the anti-velvet process of the present embodiment are shown in Table 2:

[0035] Table 2

[0036]

[0037]

Embodiment 3

[0039] A kind of nylon weft elastic pipeline cloth anti-velvet technology

[0040] The velvet-proof process of nylon weft elastic pipeline includes the following steps in sequence: blank inspection → unwinding → GO desizing → BO desizing → pre-shrinking drying → blank setting → dyeing → overflow cylinder → dehydration → opening → pre-shrinking drying Drying→Intermediate Inspection Cloth→Styling→Packing.

[0041] The specific parameters of the anti-velvet process of the present embodiment are shown in Table 3:

[0042] table 3

[0043]

[0044]

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com