Water-based high velvet-proof finishing agent and preparation method thereof, post-treatment method of velvet-proof fabric

A finishing agent and anti-velvet technology, which is applied in fiber treatment, textiles and papermaking, fiber types, etc. It can solve the problems of low anti-drilling down performance, poor washing resistance, and low strength of fabrics, and achieve good anti-velvet effect and environmental protection performance Good, good glue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

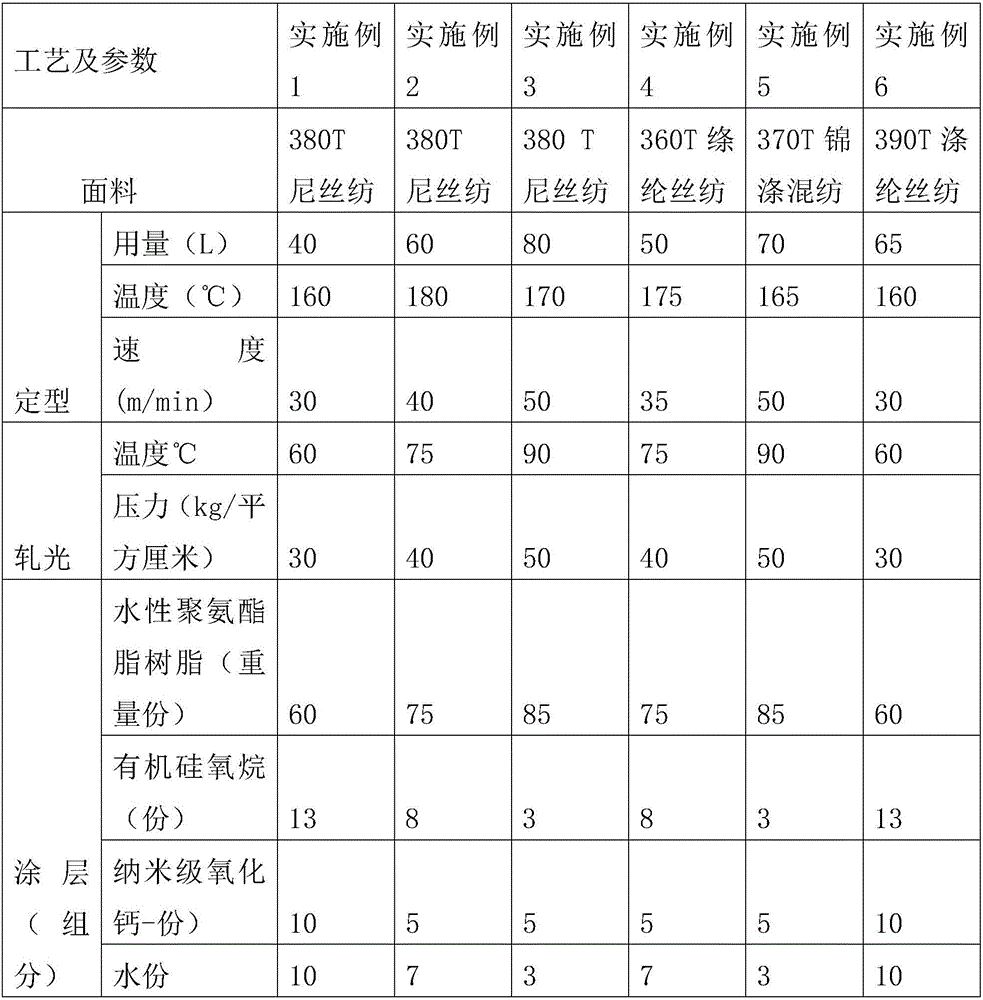

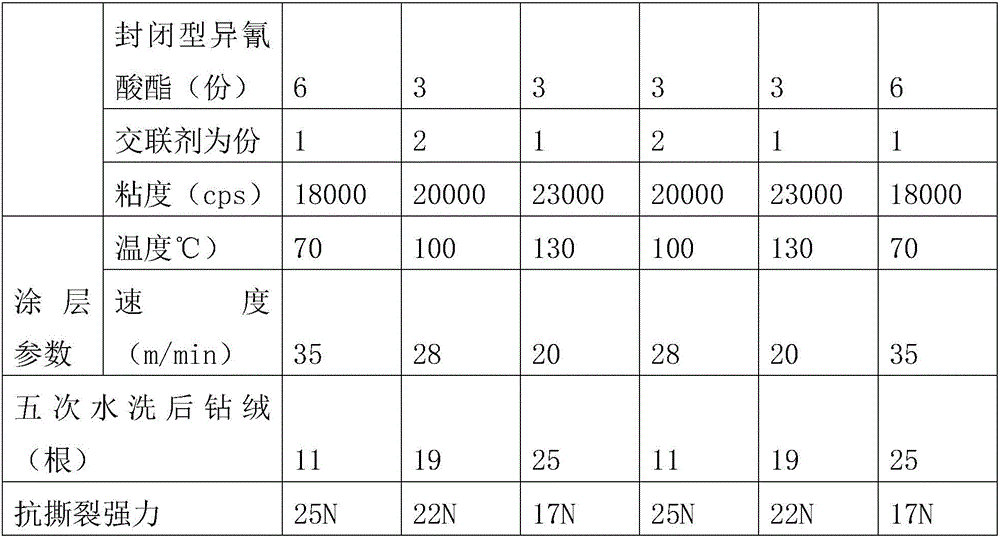

[0021] The preparation method of the water-based high anti-velvet finishing agent of the present invention is as follows, first add calcium oxide to 3-4 parts of water, stir evenly, then add water-based polyurethane resin, add organosiloxane to 3-4 parts of water, stir well and then Add the mixture of calcium oxide, water-based polyurethane resin and water that is stirred evenly, and finally add bridging agent and crosslinking agent to the mixed solution in turn, after stirring evenly, add 2-4 parts of water to adjust the viscosity of the mixed solution to 18000cps -23000cps. Adding calcium oxide into water for hydrolysis and then adding water-based polyurethane resin can prevent calcium oxide from being directly added to water-based polyurethane resin with too high viscosity to cause agglomeration, ensure water-resistant performance and reduce drilling wool. Stir the water and organosiloxane evenly first, the purpose is to disperse the organosiloxane evenly in the water-based...

Embodiment 1

[0033] Fabric: 380T ultra-light nylon spinning down fabric.

[0034] With liquid cooling reactor: the pH value is 10-12, and the cooling time is 12-24h;

[0035] Dyeing: Acid dye dyeing. PH is 3.5-6.5;

[0036] Shaping: hot air shaping. The shaping formula adopts conventional fluorocarbon resin, the dosage is 40-80g / L, citric acid is 1-2g / L, the temperature is 160°C, and the speed is 30m / min.

[0037] Calendering: calendering temperature 60°C, pressure 30kg / cm2

[0038] Coating: Adopt a conventional floating knife coating machine, the knife type is 0.1-0.5#, the distance between the knife and the bottom plate is 1-3cm, the knife height is 1-4cm, the temperature is 700°C, and the coating speed is 20m / min . The finishing agent components are: 60 parts of water-based polyurethane resin, 13 parts of organosiloxane, 10 parts of nano calcium oxide, 10 parts of water, 6 parts of bridging agent, 1 part of triethylenediamine, and the viscosity of the liquid mixture is 18000 cps. ...

Embodiment 2

[0040] Linking agent adopts dibutyltin dilaurate, and all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com