A kind of manufacturing technology of stretchy fleece-proof fabric without gall

A velvet-proof fabric and production process technology, applied in the direction of fabric surface trimming, improved hand-feeling fibers, dyeing methods, etc., can solve the problems of lightness, elasticity, dexterity and comfort, and increased cost of weakened elastic fabrics, so as to improve handfeel and increase contact. , Improve the effect of shine and shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] DETAILED DESCRIPTION The following embodiments of the case is further described in detail.

[0039] In this case relates to an elastic force of gutless proof fabric production process, comprising the steps of:

[0040] 1) pretreatment administered fabric: nylon fabric selected stretch fabric woven fabrics, a specific embodiment, selection of woven fabrics of nylon stretch fabric 20D; sequentially after desizing the fabric, a predetermined, dyeing, drying, front splash treatment; specific operation of each embodiment of the pretreatment step is as follows:

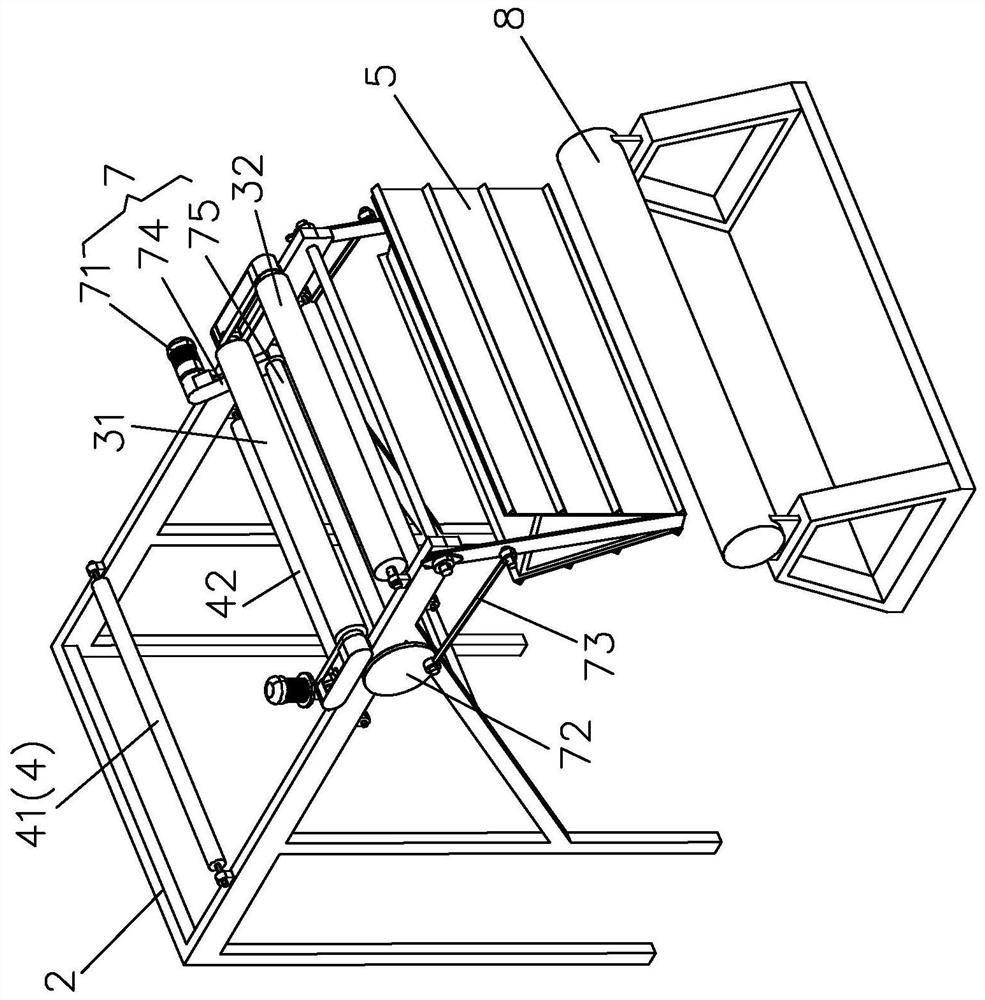

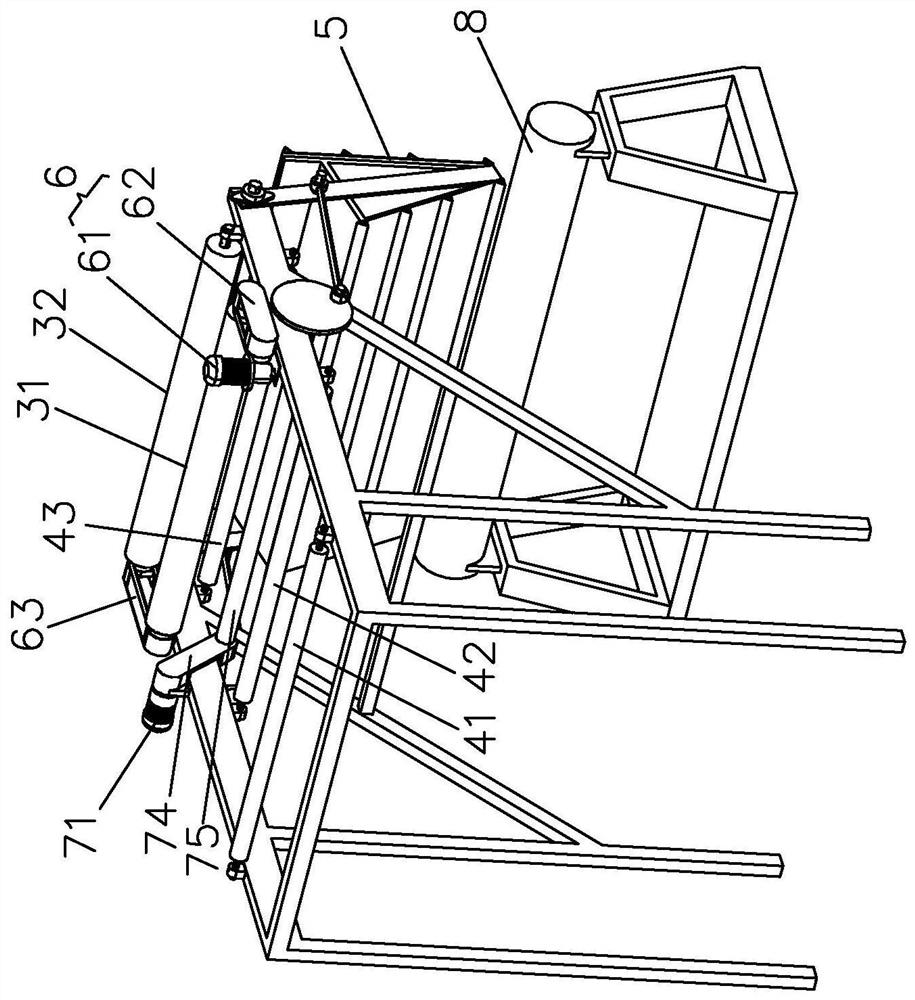

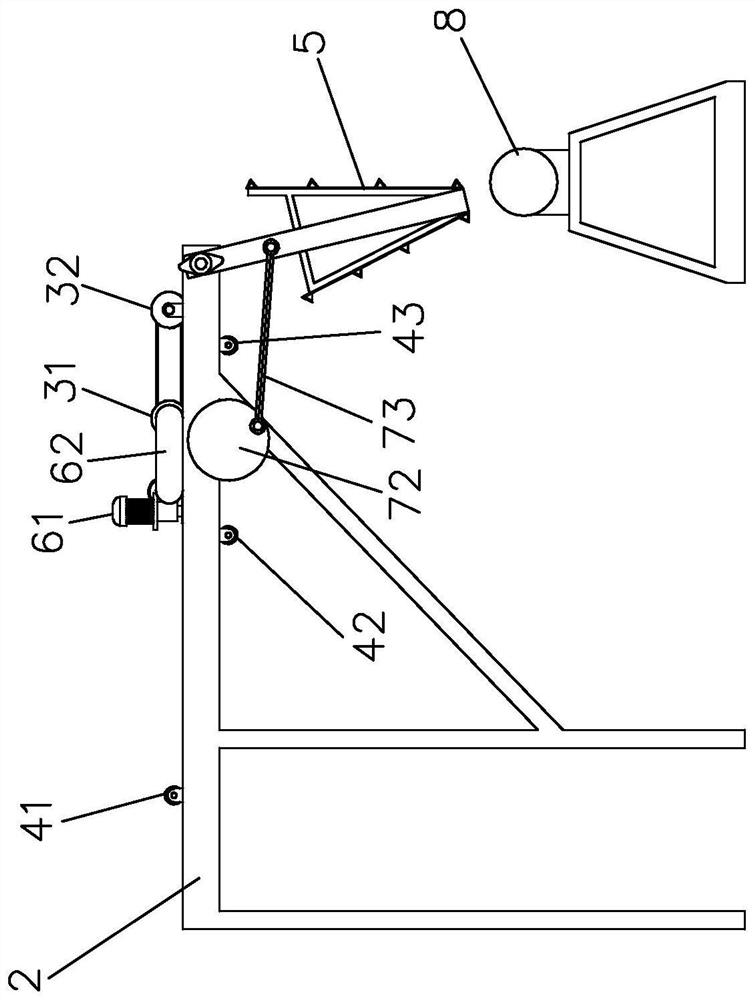

[0041] Desizing step, the desized fabric desizing processing machine, the groove 7 can be particularly tight Annealing desizing desizing machine;

[0042] Predetermined step of desizing the fabric by the predetermined setting machine, so that the width remains stable; is set to the predetermined condition, temperature 185 ℃ -190 ℃, speed of 18m / min-20m / min, width 148cm-150cm, Ultra feed 3% -5%;

[0043] Cloth before ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com