Polyolefin waste plastic self-exothermic phase change thermal cracking process

A technology for waste plastics and polyolefins, which is applied in the field of self-exothermic phase change thermal cracking process of polyolefin waste plastics, can solve the problems of not being able to eliminate white pollution, difficult to recycle and reuse, and increase operating costs, and is easy to promote on a large scale. Application, equipment manufacturing maturity, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

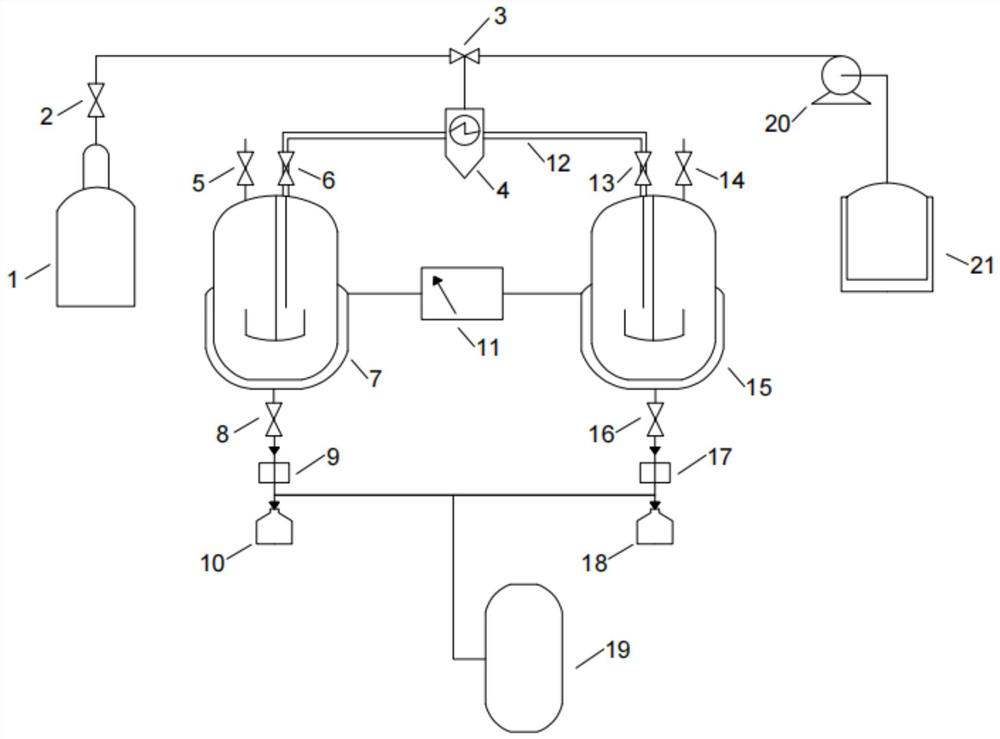

[0043] A self-exothermic phase-change pyrolysis process for polyolefin waste plastics, comprising the following steps:

[0044] (1) Carry out impurity removal and drying pretreatment to polyethylene waste plastics;

[0045] (2) Place the pretreated polyethylene waste plastics in the first high-pressure reactor 7 with a filling rate of 0.35, and feed inert gas to replace the air in the high-pressure reactor;

[0046] (3) Into the first high-pressure reactor 7, the phase builder is imported, and the phase builder is nitrogen with an initial pressure value of 1MPa;

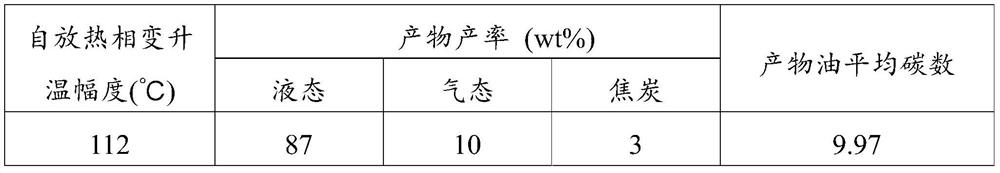

[0047] (1) Heat the first high-pressure reactor 7 to 380°C, the heating rate is 15°C / min, the internal pressure of the first high-pressure reactor 7 is 5.26MPa under the temperature condition of 380°C, and the polyethylene waste plastic undergoes a self-exothermic phase change The thermal cracking reaction produces thermal cracking products, and the average carbon numbers of the thermal cracking products and product...

Embodiment 2

[0051] A self-exothermic phase-change pyrolysis process for polyolefin waste plastics, comprising the following steps:

[0052] (1) Carry out impurity removal and drying pretreatment to polyethylene waste plastics;

[0053] (2) Place the pretreated polyethylene waste plastics in the first high-pressure reactor 7 with a filling rate of 0.35, and feed inert gas to replace the air in the high-pressure reactor;

[0054] (3) Into the first high-pressure reactor 7, import phase builder, described phase builder is the gas in the hot state from the thermal cracking reaction of the second high-pressure reactor 15 and the gas in the gas collection tank 21;

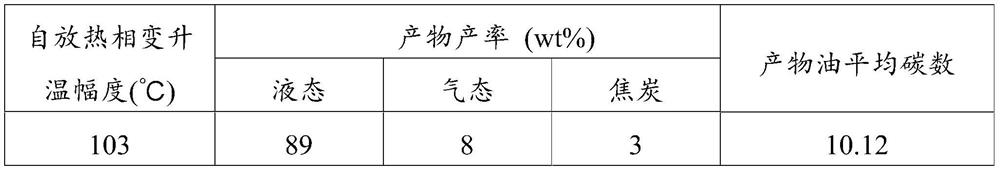

[0055] (4) Heat the first high-pressure reactor 7 to 380°C, the heating rate is 15°C / min, and the internal pressure of the first high-pressure reactor 7 is 4.27MPa under the temperature condition of 340°C, and the polyethylene waste plastic undergoes a self-exothermic phase change The thermal cracking reaction produces thermal crac...

Embodiment 3

[0059] A self-exothermic phase-change pyrolysis process for polyolefin waste plastics, comprising the following steps:

[0060] (1) Carry out impurity removal and drying pretreatment to polyethylene waste plastics;

[0061] (2) Place the pretreated polyethylene waste plastics in the first high-pressure reactor 7 with a filling rate of 0.35, and feed inert gas to replace the air in the high-pressure reactor;

[0062] (3) Into the first high pressure reactor 7, import phase builder, described phase builder is the gas in the hot state after the pyrolysis reaction from the second high pressure reactor 15 and the gas in the gas collection tank 21;

[0063] (4) Heat the first high-pressure reactor 7 to 340°C, the heating rate is 15°C / min, the internal pressure of the first high-pressure reactor 7 is 4.18MPa under the temperature condition of 340°C, and the polyethylene waste plastic undergoes a self-exothermic phase change The thermal cracking reaction produces thermal cracking pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com