Full-biodegradable straw reinforced starch material and preparation method thereof

A technology of starch materials and degradable materials, which is applied in the field of fully biodegradable straw-enhanced starch materials and its preparation, can solve problems such as environmental pollution, poor strength, and long plasticizing time, so as to reduce costs, solve processing problems, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

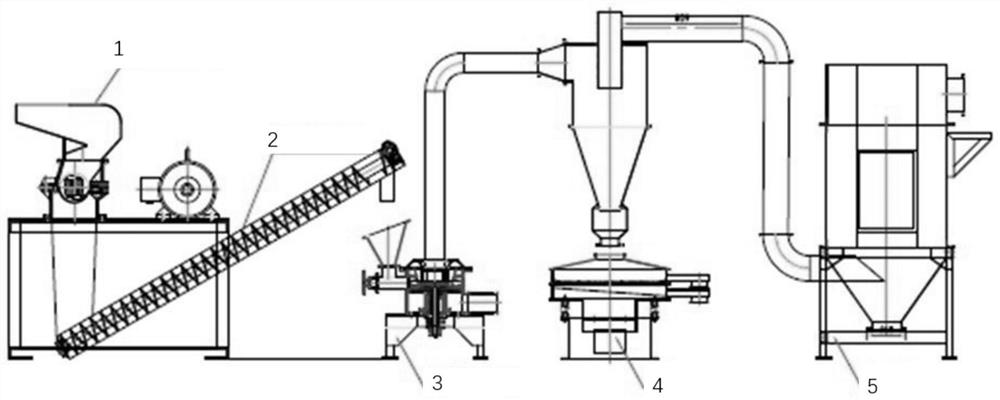

Image

Examples

Embodiment 1

[0051] This example provides a method for preparing a fully biodegradable straw-enhanced starch material.

[0052] (1) 700g starch, 200g glycerin, 100g micron calcium carbonate (10μm), 100g polyvinyl alcohol (polymerization degree 1700), 150g polylactic acid (molecular weight 60000) and 100g straw nanofibers (diameter 20nm, length 1μm) Stir in a high-speed mixer at 20°C for 20 minutes and mix evenly to obtain a premixed material;

[0053] (2) Mix the premixed material in an internal mixer at 150°C for 30 minutes;

[0054] (3) After the mixing is completed, the mixed product obtained in step (2) is directly transported to a twin-screw extruder, and mixed, extruded, and granulated in the twin-screw extruder at 150 ° C to obtain a complete Biodegradable straw-enhanced starch material.

[0055] The performance test (test standard GB / T1040.2-2006) of the obtained fully biodegradable straw-enhanced starch material is performed, and the performance is shown in Table 1.

Embodiment 2

[0057] This example provides a method for preparing a fully biodegradable straw-enhanced starch material.

[0058] (1) 700g starch, 300g glycerol complex (200g glycerol + 100g epoxidized soybean oil), 70g micron calcium carbonate (20μm), 150g polycaprolactone (molecular weight 70000) and 200g straw nanofibers (diameter 30nm, length 10 μm) was stirred in a high-speed mixer at 20°C for 30 minutes and mixed evenly to obtain a premixed material;

[0059] (2) Mix the premixed material in an internal mixer at 120°C for 30 minutes;

[0060] (3) After the mixing is completed, the mixed product obtained in step (2) is directly transported to a twin-screw extruder, and mixed, extruded, and granulated in the twin-screw extruder at 130 ° C to obtain a complete Biodegradable straw-enhanced starch material.

[0061] The performance test (test standard GB / T1040.2-2006) of the obtained fully biodegradable straw-enhanced starch material is performed, and the performance is shown in Table 1. ...

Embodiment 3

[0063] This example provides a method for preparing a fully biodegradable straw-enhanced starch material.

[0064] (1) 700g starch, 300g glycerol complex (200g glycerol + 100g formamide), 50g nano-calcium carbonate (60nm), 250g polybutylene succinate (molecular weight 100000) and 100g straw nanofiber (diameter 20nm , with a length of 100 μm) was stirred in a high-speed mixer at 50°C for 20 minutes and mixed evenly to obtain a premixed material;

[0065] (2) Mix the premixed material in an internal mixer at 150°C for 10 minutes;

[0066] (3) After the mixing is completed, the mixed product obtained in step (2) is directly transported to the twin-screw extruder, and mixed, extruded, and granulated in the twin-screw extruder at 170 ° C to obtain a complete Biodegradable straw-enhanced starch material.

[0067] The performance test (test standard GB / T1040.2-2006) of the obtained fully biodegradable straw-enhanced starch material is performed, and the performance is shown in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com