Foam extrusion vehicle and implementation method thereof

A foam and extrusion shaft technology, applied in the field of foam extrusion vehicles, can solve the problems of high cost, bulky, complex structure, etc., achieve the effects of reducing loss, solving a large amount of accumulation, and improving the heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

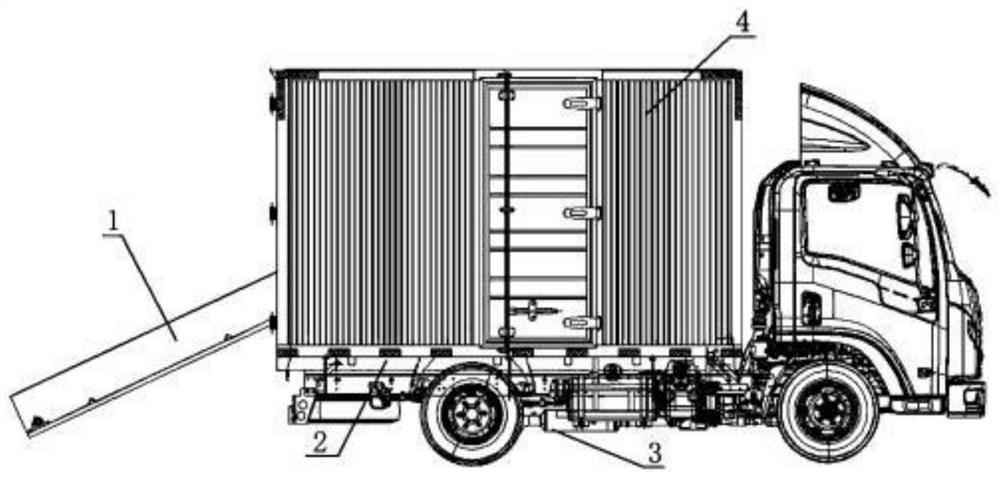

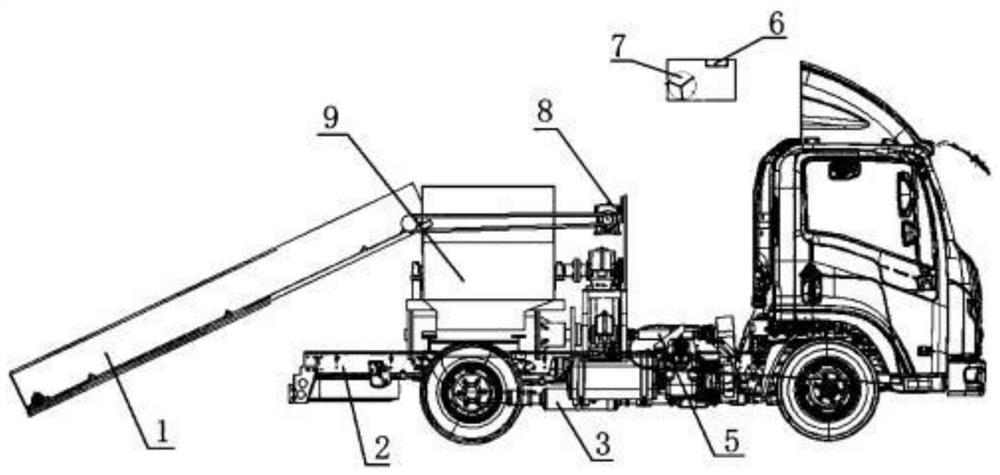

[0039] Such as Figure 1-4 As shown, a foam extrusion vehicle disclosed in this embodiment includes a motor vehicle with a special chassis 2 and a fuel engine. A foam treatment device 9 is installed on the special chassis 2 and a power unit connected to the foam treatment device 9 An output device 5, the power output device 5 is connected to the fuel engine;

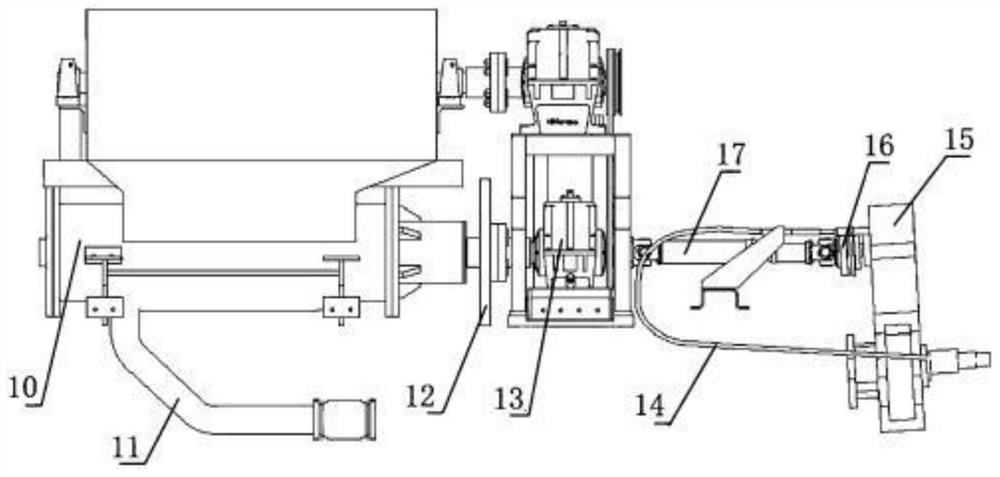

[0040] The foam processing device 9 includes a conveyor belt 1 for inputting waste foam from the outside, a worm gear reducer 8 connected to one end of the conveyor belt 1 for providing conveying power, and a foam extruding device 10 arranged below the outlet of the conveyor belt 1 , a waste heat utilization device 11 connected to the foam extruding device 10, a flywheel 12 connected to the rotating shaft of the foam extruding device 10, one end connected to the rotating shaft of the foam extruding device 10 and the other end connected to the power output device 5 Reducer unit 13, and a waste gas collection device for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com