Quick dismounting device and method for cotter pin

A dismantling device and cotter pin technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of easy damage to nuts and other parts, lack of quick disassembly methods, and difficulty in disassembly by ordinary tools, so as to improve operational stability and speed. The effect of dismantling and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

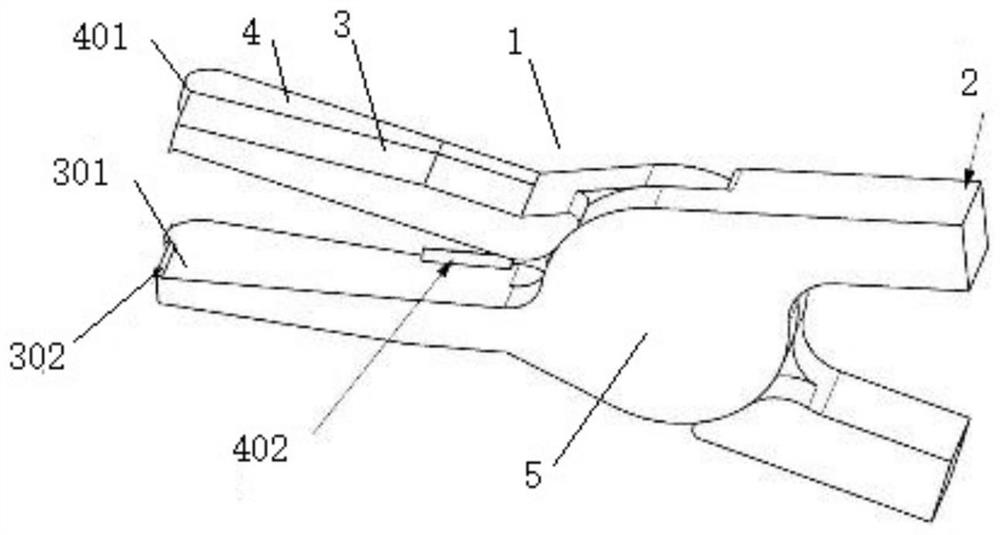

[0043] A cotter pin quick release device such as Figure 1-Figure 4 As shown, it includes two clamping parts 1 that are movable riveted with each other, each of the clamping parts 1 includes a clamping area and a gripping area 2 connected with the clamping area, and the clamping area includes a clamping part 3 and The support member 4, the clamping member 3 and the support member 4 are on the same horizontal plane;

[0044] The clamping member 3 includes a clamping end 301 and a first connecting end, the first connecting end is connected to the gripping area 2 , and the end of the clamping end 301 is provided with a clamping edge 302 .

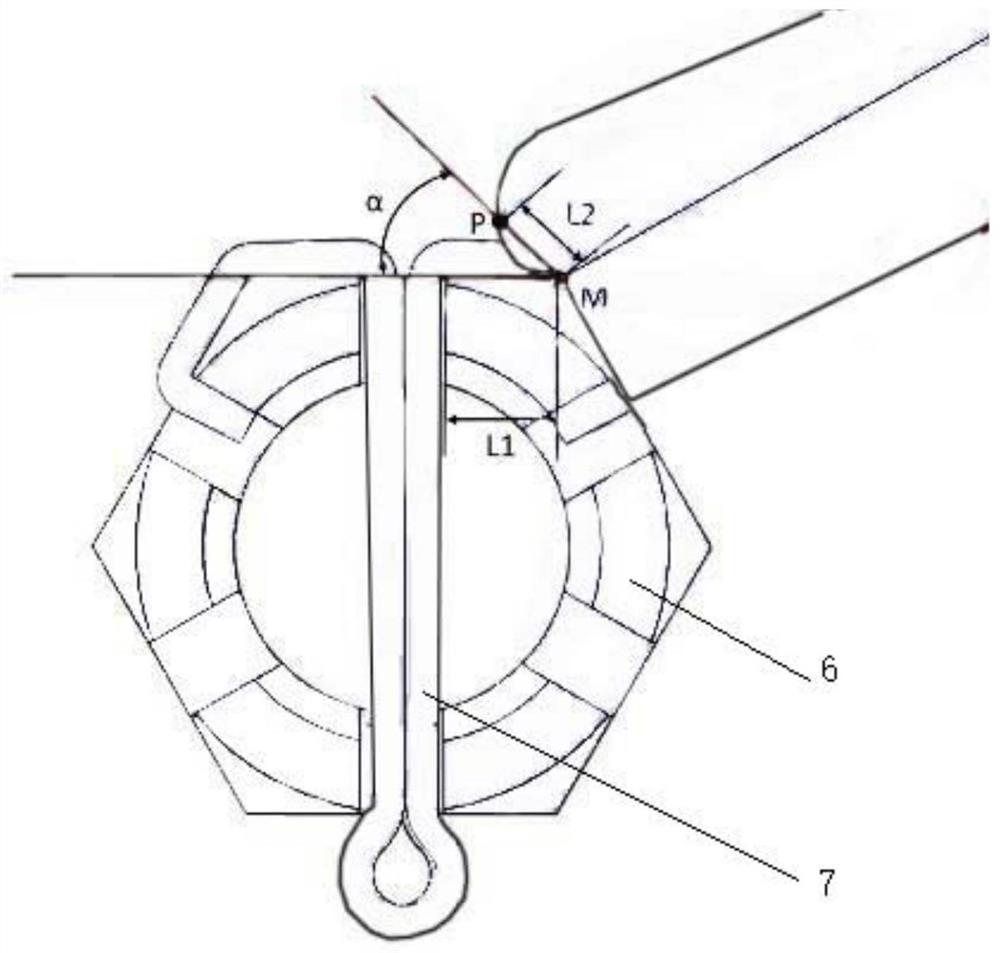

[0045] The support member 4 includes an arc-shaped support end 401 and a second connection end. The clamping end 301 and the arc-shaped support end 401 are connected side by side to form a connection point. The angle formed between is identical with the included angle of nut 6;

[0046] One of the support members 4 is also provided with a ja...

Embodiment 2

[0065] A method for quick disassembly of cotter pins, comprising the following steps:

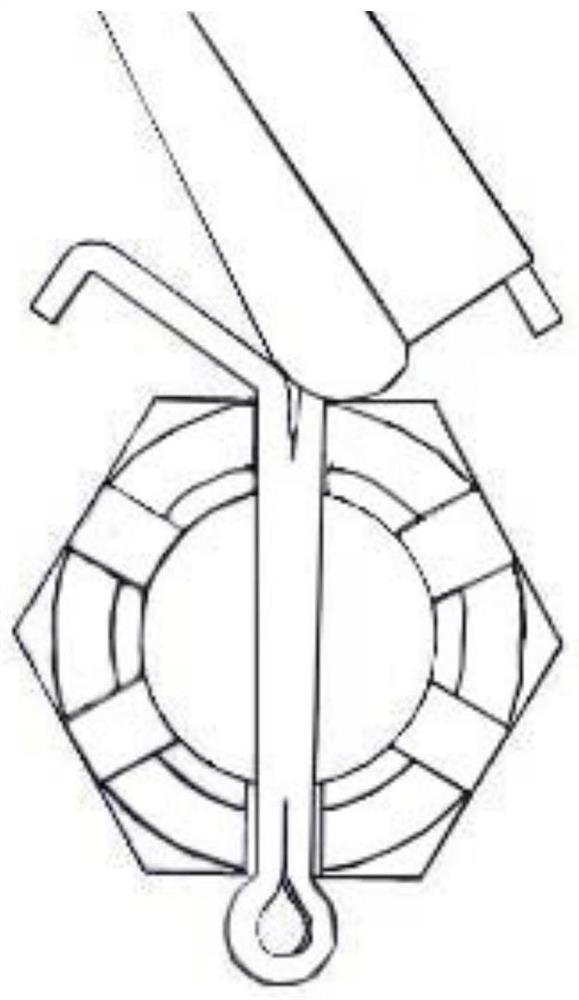

[0066] (1) Bending the cotter pin in reverse: the clamping edges 302 of the two clamping parts 3 in the quick release device of the cotter pin 7 clamp the tail of the cotter pin 7 wound on the end face of the nut 6, and the arc of the supporting part 4 The support end 401 is supported by the end surface of the other end of the nut 6, rotates according to the arc of the arc-shaped support end 401, reversely bends the tail of the cotter pin 7, and restores the tail of the cotter pin 7 from a tightly installed state to a free open state;

[0067] (2) Rotate the cotter pin: Use the cotter pin 7 quick release device to clamp the tail of the cotter pin 7, and rotate the cotter pin 7 around its own axis by 90°; the 90 ° rotation is mainly to facilitate the cotter pin 7 quick disassembly device to align the cotter pin The cotter pin 7 tail of 7 is cut;

[0068] (3) Trimming the cotter pin: Utilize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com