Resin composition and resin product

A technology of resin composition and thermoplastic resin, which is applied in the direction of manufacturing tools, additive manufacturing, additive processing, etc., can solve the problems of not studying multi-component copolymers, and achieve the effect of excellent fracture characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

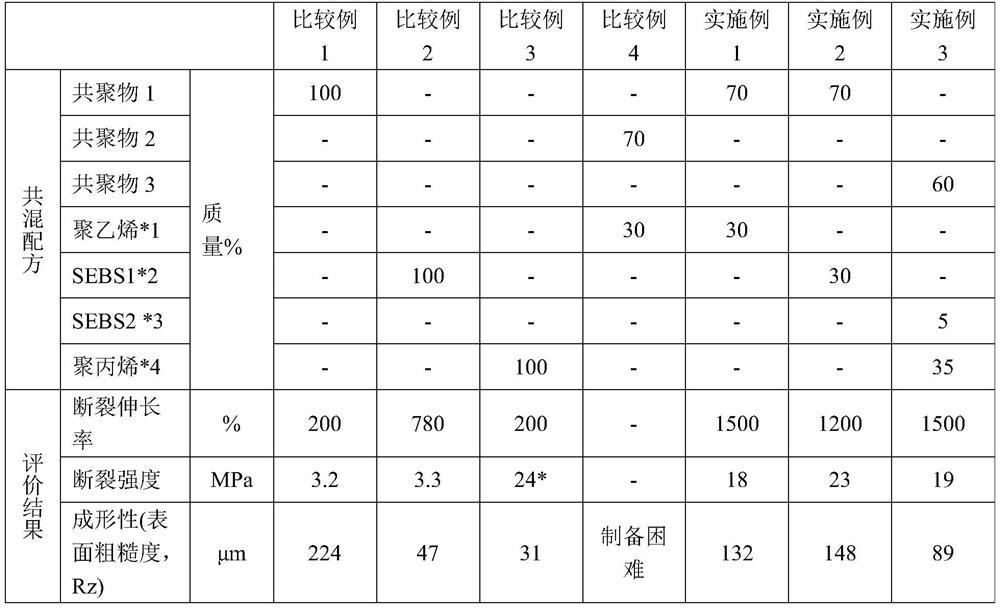

Embodiment 1~3 and comparative example 1~3

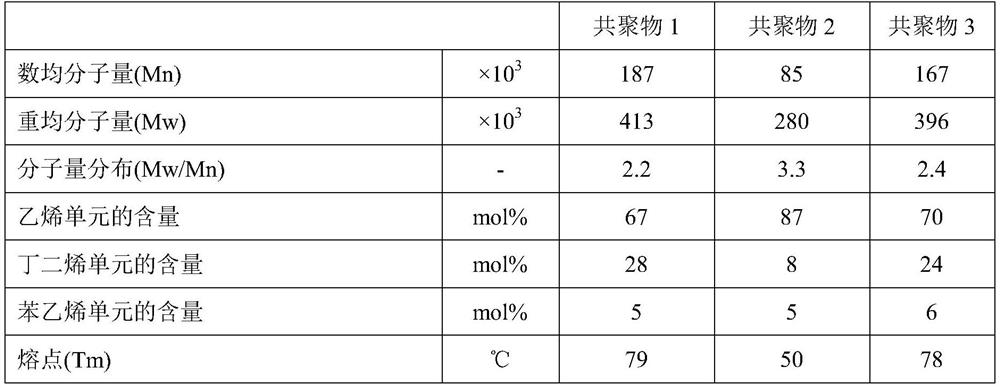

[0141] According to the blending formula shown in the following Table 2, each copolymer synthesized as above, commercially available thermoplastic resin (B) and / or or commercially available thermoplastic elastomer (C) to prepare filament samples for FDM 3D printers.

[0142] Mixing and kneading were performed under the conditions of mixing and kneading temperature: 170° C., number of revolutions of the screw: 100 rpm, and mixing and kneading time: 3 minutes. These conditions were set such that the torque during the mixing and kneading process did not exceed a maximum value of 8000N.

[0143] Further, when the filament sample was extruded after mixing and kneading, it was carried out by using a nozzle (diameter: 1.25mm) and reducing the number of revolutions of the screw to 10rpm so that the filament sample had a diameter in the range of 1.7mm to 1.8mm extrude.

[0144] The filament sample thus extruded was then wound at a winding speed of 10 mm / sec by using a fiber winder (a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com