Carbon-based inverse spinel copper ferrite fuel cell cathode material constructed with collagen fiber/nanofiber composite airgel as a template

A fuel cell cathode and composite airgel technology, which is applied in battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of single synthesis cost, toxicity, and high cost of Pt-based catalytic materials of precursors, and achieve excellent limiting current, Good electrical conductivity and the effect of maintaining the integrity of the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

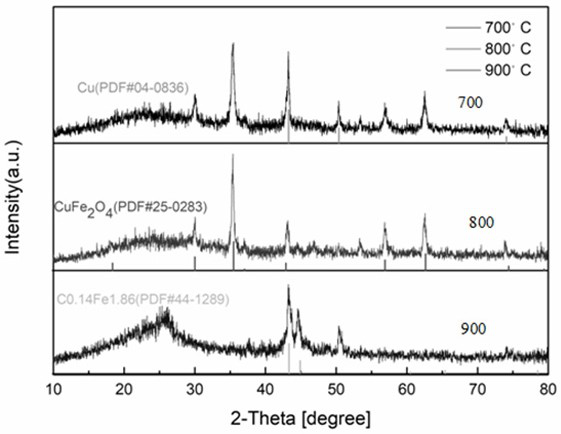

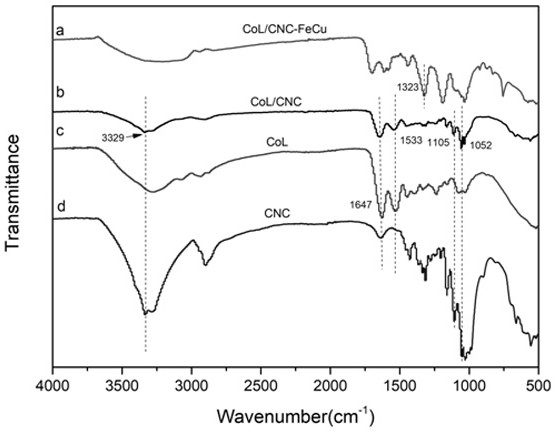

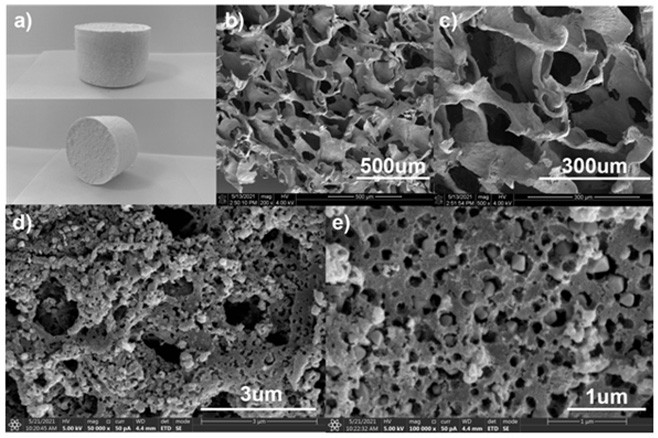

[0036] A carbon-based inverse spinel copper ferrite fuel cell cathode material is constructed by using collagen fiber / nanofiber composite aerogel as a template, and the preparation method thereof comprises the following steps:

[0037] (1) Weigh cotton into a three-neck round-bottomed flask, add concentrated sulfuric acid (98wt%) and deionized water, stir the water bath at a constant speed in a water bath for a period of time, add deionized water to dilute the sulfuric acid to terminate the hydrolysis reaction, After setting, remove the supernatant, and then centrifuge the suspension at high speed for many times until the supernatant becomes turbid, collect the turbid liquid, put it in a dialysis bag (MD44-14000) and dialyze until the solution is neutral to obtain nanofiber crystals. (CNC) solution;

[0038] (2) Dissolve the white skin powder in a mixed solution containing NaOH and NaCl, and shake it in a water bath to obtain a collagen fiber solution;

[0039] (3) Mix and st...

Embodiment

[0053] (1) Weigh 3g of cotton into a three-neck round bottom flask, add 13mL of concentrated sulfuric acid (98%) and 13mL of deionized water, stir at a constant speed in a 45°C water bath for 1.5h, and then add 50mL of deionized water to dilute sulfuric acid to stop Hydrolysis reaction, after standing, remove the supernatant, then centrifuge the lower layer suspension at 10000rpm / min in a high-speed centrifuge, 10min / time, until the supernatant becomes turbid, collect the turbid solution, and put it in a dialysis bag (MD44- 14000) to obtain a 0.01wt% nanofiber crystal (CNC) solution;

[0054] (2) Dissolve 1 g of white skin powder in 50 mL of a mixed solution containing NaOH and NaCl, and shake it in a water bath at 30 °C for 24 h to prepare a collagen fiber solution; the mixed solution used consists of 25 mL, 0.1 mol / L NaOH solution and 25 mL, 2 mol / L of NaCl solution mixed;

[0055] (3) Take 50 mL of nanofiber crystal solution and 50 mL of collagen fiber solution, mix and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com