A kind of porous electrode and its preparation method and lithium battery

A porous electrode and lithium battery technology, applied in the field of materials, can solve the problems of high cost of expanded graphite, difficult to scale, shortened cruising range, etc., and achieve the effects of simple and feasible preparation method, reducing battery internal resistance, and improving rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

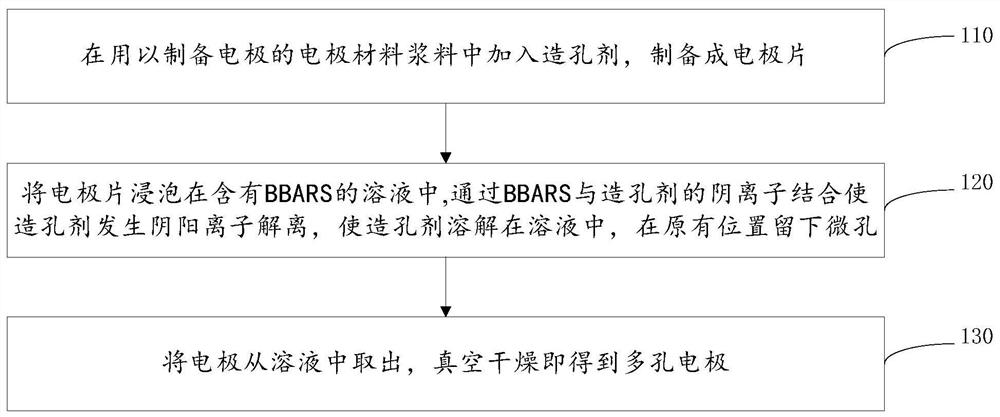

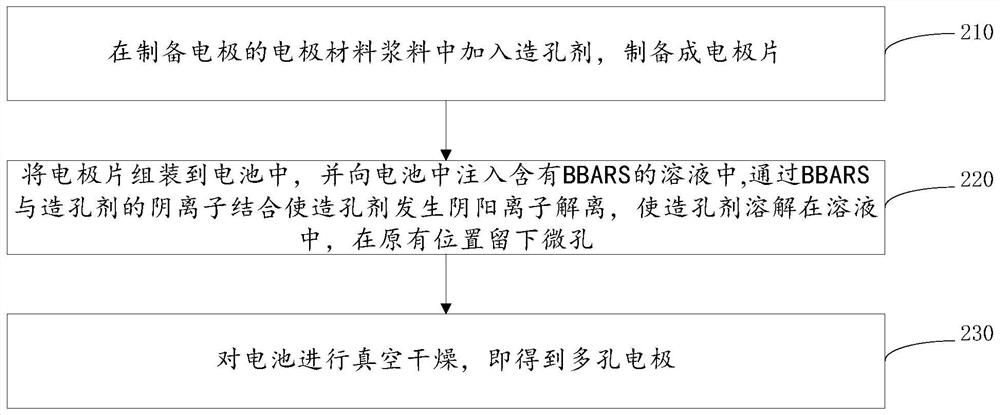

[0034] The present invention proposes a method for preparing a porous electrode, which can be realized in the following two specific ways. figure 1 A flow chart of a method for preparing a porous electrode provided by an embodiment of the present invention; figure 2 A flow chart of another method for preparing a porous electrode provided in an embodiment of the present invention. The following descriptions will be made in conjunction with these two flow charts respectively.

[0035] Such as figure 1 Shown, the main steps of the preparation method of a kind of porous electrode of the present invention comprise:

[0036] Step 110, adding a pore-forming agent to the electrode material slurry used to prepare the electrode to prepare an electrode sheet;

[0037] Step 120, soaking the electrode sheet in a solution containing BBARS, through the combination of BBARS and the anion of the pore-forming agent, the anion and cation of the pore-forming agent are dissociated, so that the...

Embodiment 1

[0056] In this embodiment, the boron-based anion acceptor compound is pentafluorophenylboron oxalate (PFPBO), and its structural formula is as follows:

[0057]

[0058] Choose LiNi 0.5 co 0.2 mn 0.3 o 2 As the positive electrode material, the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 Mix it with CNTs, LiF, and polyvinylidene fluoride (PVDF) according to the ratio of mass ratio 97.2:1.3:0.2:1.3, coat it on the aluminum foil current collector, dry it in an oven, and then roll it with a roller press to make Obtain the required positive electrode sheet;

[0059] Select artificial graphite as the negative electrode material, and mix graphite, sodium carboxymethylcellulose (CMC), CNTs, LiF, and binder styrene-butadiene rubber (SBR) according to the mass ratio of 95.7:1.4:0.8:0.1:2.0. Coated on the copper foil current collector, dried in an oven, and then rolled by a roller press to obtain the required negative electrode sheet;

[0060] The ceramic-coated po...

Embodiment 2

[0064] In this embodiment, the boron-based anion acceptor compound is tris(pentafluorophenyl)borane (TPFPB), and its structural formula is as follows:

[0065]

[0066] Choose LiNi 0.5 co 0.2 mn 0.3 o 2 As the positive electrode material, the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 with CNTs, Li 2 o 2 , PVDF is mixed evenly according to the ratio of 97.1:1.3:0.3:1.3, coated on the aluminum foil current collector, dried in an oven, and then rolled by a roller press to obtain the required positive electrode sheet;

[0067] Select nano-silicon as the negative electrode material, mix nano-silicon, CMC, CNTs, LiF, and SBR according to the ratio of 94.3:1.5:2.0:0.2:2.0, coat it on the copper foil current collector, dry it in an oven, and then roll it The press is rolled to obtain the required negative electrode sheet;

[0068] In a glove box with moisture less than 0.1ppm, oxygen less than 0.1ppm, and filled with argon, DEC and EC were mixed uniformly at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com