A pre-pressing device for non-woven fabric processing

A technology of non-woven fabrics and conveyor belts, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of rolling, non-involving, unevenness and other problems of fabrics with different thicknesses, and achieve the effect of reducing unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

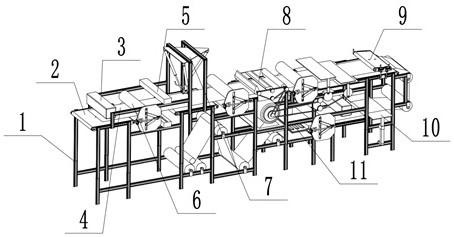

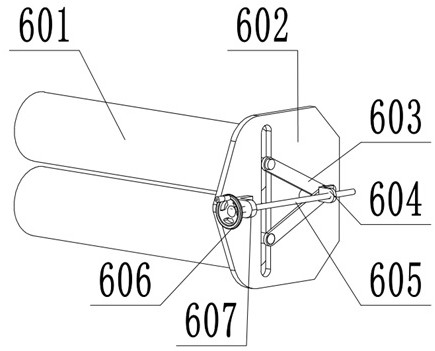

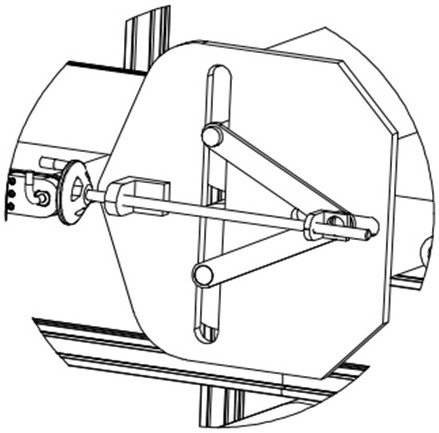

[0022] Example: such as Figure 1-Figure 9 The shown pre-pressing device for non-woven fabric processing includes a seat frame 1, a transmission belt 2, a nozzle 3, a non-woven fabric 4, a grating 5, a first flattening mechanism 6, a respraying mechanism 7, and a second flattening mechanism 8. Conveyor belt flattening mechanism 9, weighing mechanism 10, ironing mechanism 11; seat frame 1 is a fixed body of the whole device, and all the other mechanisms are arranged on seat frame 1, and seat frame 1 is divided into upper and lower layers altogether. The transmission belt 2 is set on the frame 1, mainly used to transmit the non-woven fabric 4 to be processed, the nozzle 3 is set on the frame 1, and is used to spray fiber filaments to process the non-woven fabric, the grating 5 is set on the frame 1, and is used to detect After being flattened by the first flattening mechanism 6, whether the non-woven fabric 4 is even or not, start the re-spray mechanism 7 when unevenness occurs,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com