Production method for extracting crude rice oil by enzyme method

A technology of enzymatic extraction and production method, which is applied in the direction of fat oil/fat production, fat production, fat oil/fat refining, etc. It can solve the problems of high price of enzyme substances, large output of three wastes, limited application, etc., and solve the loss of nutrients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

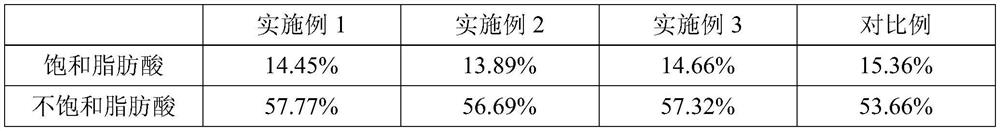

Embodiment 1

[0018] A production method for enzymatically extracting crude oil from rice oil, the specific method is as follows:

[0019] (1) Rice bran screening: pick out impurities such as stones and broken rice in the rice bran.

[0020] (2) Rice bran sieving: the rice bran is passed through a 40-mesh sieve.

[0021] (3) Soaking: Take 100 g of sieved rice bran, add it to 200 ml of water and soak for 1 hour.

[0022] (4) Wall breaking: filter the water in the rice bran soaked in step (3), add 100 ml of hydrogen peroxide solution with a concentration of 1% to the filter cake, and stir at 15° C. for 8 hours.

[0023] (5) Enzymolysis: the slurry after the wall breaking in the detection step (4), the starch potassium iodide test paper does not change color, and there is no residual hydrogen peroxide in the slurry. At this time, the pH of the slurry is 6-7. Use acetic acid to adjust the pH of the slurry to 5-6, then heat up to 30-40° C., add 0.5 g of a compound enzyme agent with a ratio of ...

Embodiment 2

[0027] A production method for enzymatically extracting crude oil from rice oil, the specific method is as follows:

[0028] (1) Rice bran screening: pick out impurities such as stones and broken rice in the rice bran.

[0029] (2) Rice bran sieving: the rice bran is passed through a 40-mesh sieve.

[0030] (3) Soaking: Take 100 g of sieved rice bran, add it to 200 ml of water and soak for 1 hour.

[0031] (4) Wall breaking: filter the water in the rice bran soaked in step (3), add 100 ml of 2% hydrogen peroxide solution to the filter cake, and stir at 15° C. for 10 h.

[0032] (5) Enzymolysis: the slurry after the wall breaking in the detection step (4), the starch potassium iodide test paper does not change color, and there is no residual hydrogen peroxide in the slurry. At this time, the pH of the slurry is 5-6, and then the temperature is raised to 30-40°C, and 0.8 g of a compound enzyme agent with a ratio of 1:1 of cellulase and protease is added, and stirred for 1 hour...

Embodiment 3

[0036] A production method for enzymatically extracting crude oil from rice oil, the specific method is as follows:

[0037] (1) Rice bran screening: pick out impurities such as stones and broken rice in the rice bran.

[0038] (2) Rice bran sieving: the rice bran is passed through a 40-mesh sieve.

[0039] (3) Soaking: Take 100 g of sieved rice bran, add it to 200 ml of water and soak for 1 hour.

[0040] (4) Wall breaking: filter the water in the rice bran soaked in step (3), add 100 ml of 3% hydrogen peroxide solution to the filter cake, and stir at 15° C. for 12 hours.

[0041] (5) Enzymolysis: the slurry after the wall breaking in the detection step (4), the starch potassium iodide test paper does not change color, and there is no residual hydrogen peroxide in the slurry. At this time, the pH of the slurry is 4, adding sodium hydroxide to adjust the pH of the slurry to 5-6, then warming up to 30-40°C, adding 0.6g of a compound enzyme agent with a ratio of cellulase and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com