Waste cellulose acetate fiber-based regenerated cellulose aerogel and preparation method thereof

A regenerated cellulose and fiber-based technology, which is applied to the field of waste acetate-cellulose-based regenerated cellulose aerogel and its preparation, can solve the problems that waste cigarette filters cannot be efficiently reused, etc. , the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

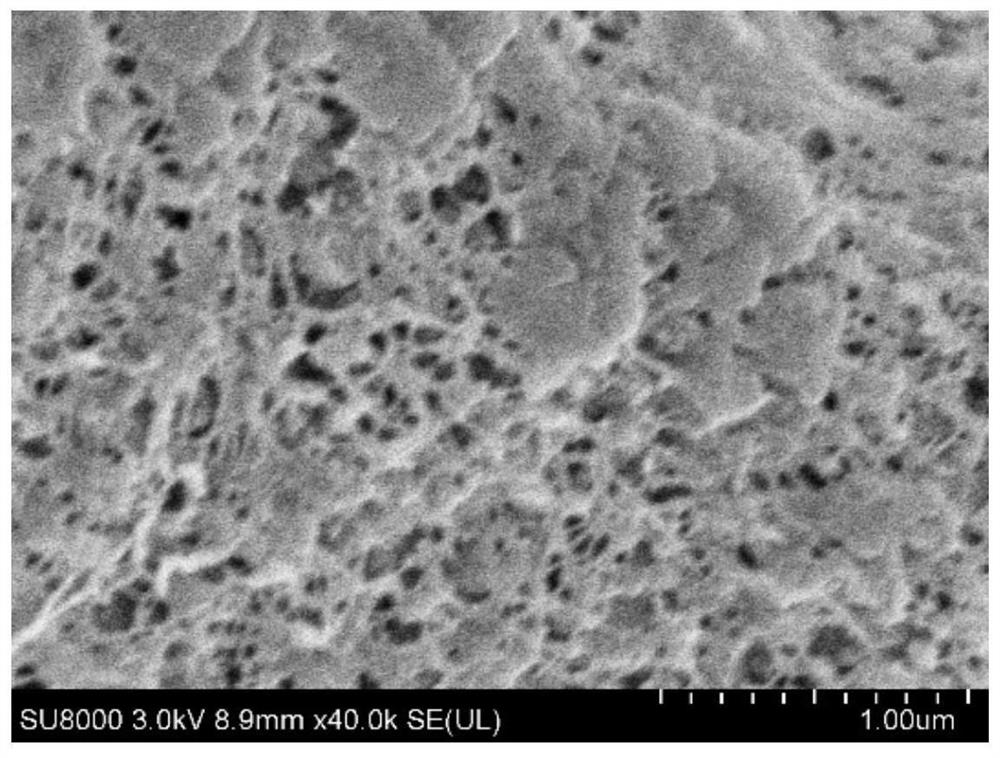

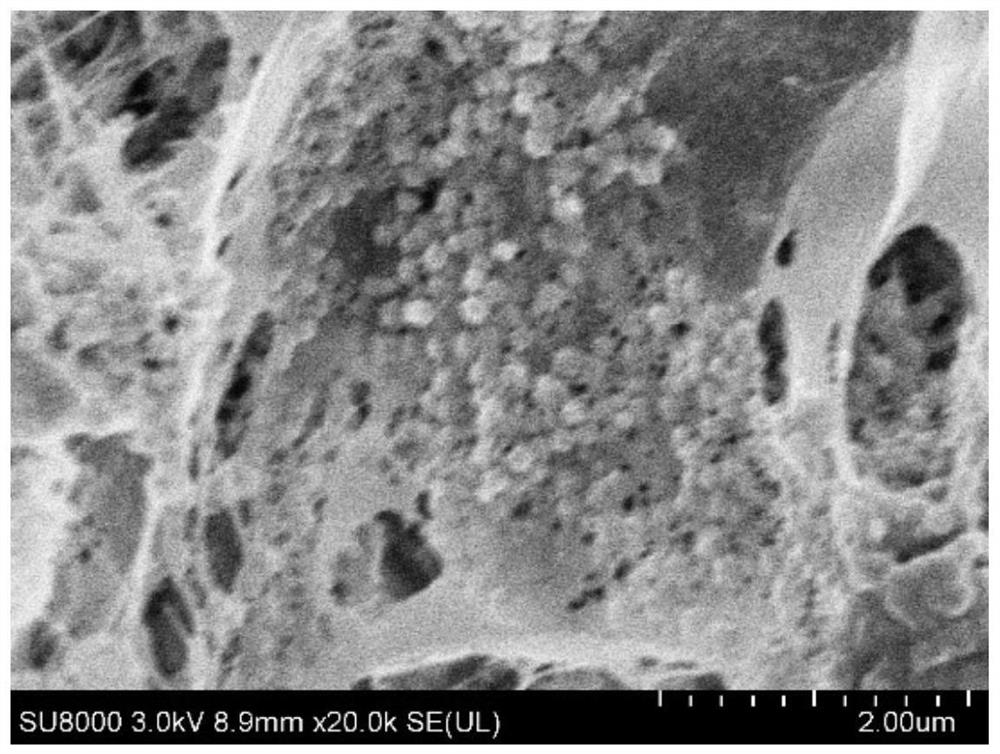

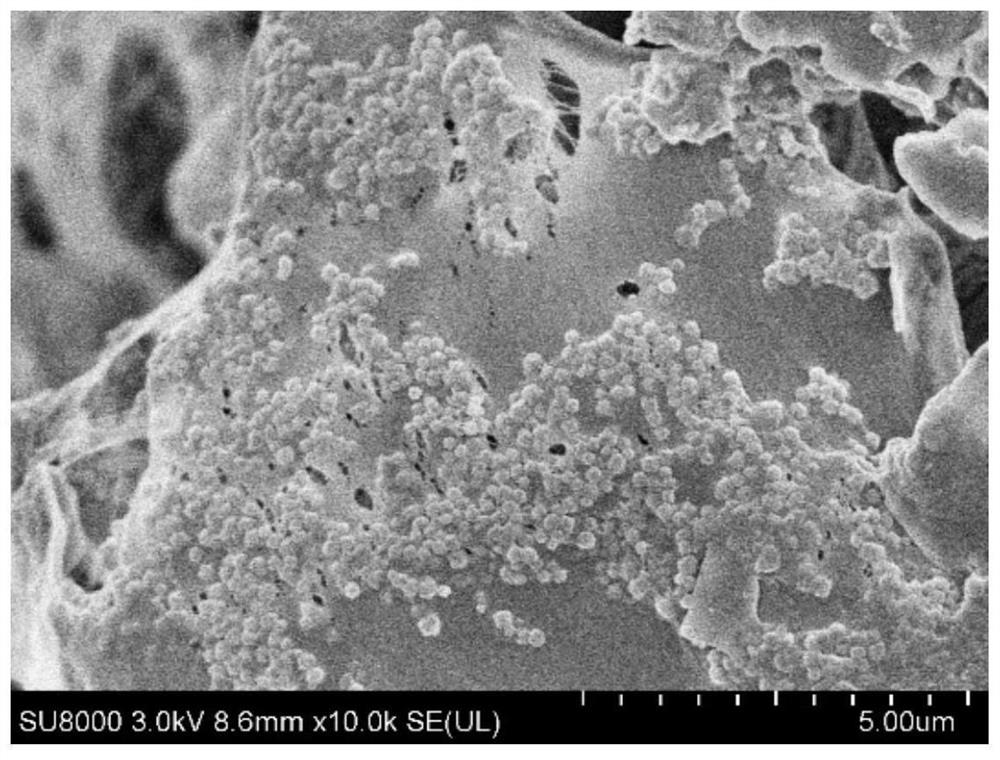

[0036] 3.5 g of sodium hydroxide and 6 g of urea were dissolved in 40.5 g of deionized water, and then placed in a refrigerator for 20 min. 2 g of the recovered cigarette filter was dissolved in the prepared sodium hydroxide / urea aqueous solution, and then frozen for 12 h. Then the frozen solution system was thawed at room temperature, and 50 mL of ethanol was added to vigorously stir to precipitate regenerated cellulose, and left to stand for 24 hours to obtain a mixed solution containing regenerated cellulose. Then the mixed solution containing the regenerated cellulose was washed by centrifugation for 6 times at a rotating speed of 8000r / min, and each time was 5min. Then dry at 60°C to obtain regenerated cellulose. 1mmol of zinc nitrate and 4mmol of 2-methylimidazole were respectively dissolved in 25mL of methanol solution, and then the two solutions were mixed and stirred for 10min to obtain a mixed solution. The prepared regenerated cellulose was dispersed in the mixed ...

Embodiment 2

[0039] 3.5 g of sodium hydroxide and 6 g of urea were dissolved in 40.5 g of deionized water, and then placed in a refrigerator for 20 min. 1 g of the recovered cigarette filter was dissolved in the prepared sodium hydroxide / urea aqueous solution, and then frozen for 12 hours. Then the frozen solution system was thawed at room temperature, and 50 mL of ethanol was added to vigorously stir to precipitate regenerated cellulose, and left to stand for 24 hours to obtain a mixed solution containing regenerated cellulose. Then the mixed solution containing the regenerated cellulose was centrifuged and washed 8 times at a rotation speed of 10000 r / min, and each time was 5 minutes. Then dry at 80°C to obtain regenerated cellulose. 1mmol of zinc nitrate and 4mmol of 2-methylimidazole were respectively dissolved in 25mL of methanol solution, and then the two solutions were mixed and stirred for 10min to obtain a mixed solution. The prepared regenerated cellulose was dispersed in the m...

Embodiment 3

[0042] 14 g of sodium hydroxide and 24 g of urea were dissolved in 162 g of deionized water, and then placed in a refrigerator for 20 min. 5 g of recovered cigarette filters were dissolved in the prepared sodium hydroxide / urea aqueous solution, and then frozen for 12 h. Then the frozen solution system was thawed at room temperature, and 150 mL of ethanol was added to vigorously stir to precipitate the regenerated cellulose, and left to stand for 24 hours to obtain a mixed solution containing regenerated cellulose. Then the mixed solution containing the regenerated cellulose was centrifuged and washed 10 times at a rotational speed of 10000 r / min, each time for 5 minutes. Then dry at 65°C to obtain regenerated cellulose. 4mmol of zinc nitrate and 16mmol of 2-methylimidazole were respectively dissolved in 25mL of methanol solution, and then the two solutions were mixed and stirred for 20min to obtain a mixed solution. The prepared regenerated cellulose was dispersed in the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com