A kind of preparation method and application of ionic liquid conductive elastomer

A technology of ionic liquids and elastomers, applied in applications, cable/conductor manufacturing, circuits, etc., to achieve the effects of enhancing long-term use stability, improving mechanical properties, and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

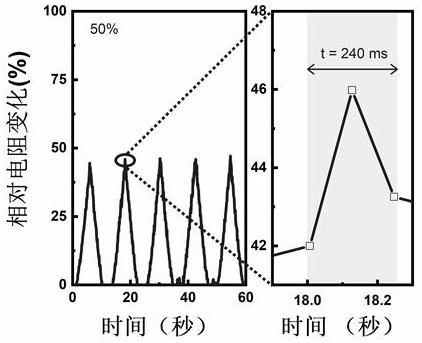

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A preparation method of an ionic liquid conductive elastomer, comprising the following steps:

[0027] Step 1: modifying the nano-silica to obtain amino-modified silica nanoparticles with amino groups on the surface;

[0028] Step 2: modifying the above-mentioned amino-modified silica nanoparticles to obtain vinyl silica nanoparticles with vinyl groups on the surface;

[0029] Step 3: Add the above-mentioned vinyl silica nanoparticles, ionic liquid, and butyl acrylate into a test tube, ultrasonically disperse for 10 min to obtain a homogeneous precursor solution, add a photoinitiator, and perform photoinitiation under ultraviolet light for 60 minutes. ~120min, the ionic liquid conductive elastomer was obtained.

[0030] Preferably, the amino-modified silica nanoparticles in step 1 of the present invention are specifically: dissolving the silica nanoparticles with a solvent, then adding a silane coupling agent, continuously heating and stirring for reaction, centrifugal...

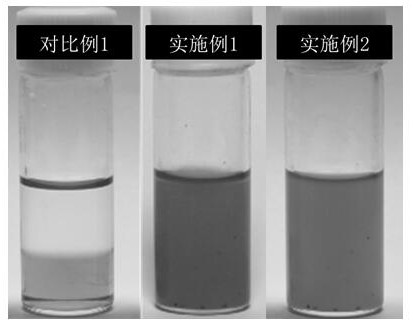

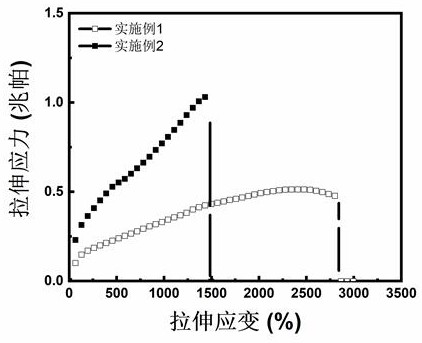

Embodiment 1

[0041] Step 1: Dissolve 3.5 g of silica and 5 mL of silane coupling agent in 200 mL of toluene, continue to heat and stir in an oil bath at 90° C. for 12 h, centrifuge for precipitation, and freeze-dry to obtain amino-modified silica nanoparticles.

[0042] Step 2: Dissolve 1 amino-modified silica nanoparticles and 1 mL of methacryloyl chloride in 20 mL of toluene, stir and react at room temperature for 12 h, centrifuge for precipitation, and freeze-dry to obtain vinyl silica nanoparticles.

[0043] Step 3: Dissolve 100 mg of vinyl silica nanoparticles, 10 mg of photoinitiator, and 1 mL of ionic liquid in 1 mL of butyl acrylate monomer, and place the mixed solution in an ultrasonic disperser for uniform dispersion to obtain a precursor solution.

[0044] Step 4: Pour the precursor solution into the mold, place it in an ultraviolet photoreactor, and initiate the reaction with light for 2 hours to prepare an ionic liquid conductive elastomer.

Embodiment 2

[0046] The preparation was carried out according to the preparation method of Example 1, except that the addition amount of the vinyl silica was 200 mg, and Example 2 was prepared.

[0047]Step 1: Dissolve 3.5 g of silica and 5 mL of silane coupling agent in 200 mL of toluene, continue to heat and stir in an oil bath at 90° C. for 12 h, centrifuge for precipitation, and freeze-dry to obtain amino-modified silica nanoparticles.

[0048] Step 2: Dissolve 1 amino-modified silica nanoparticles and 1 mL of methacryloyl chloride in 20 mL of toluene, stir and react at room temperature for 12 h, centrifuge for precipitation, and freeze-dry to obtain vinyl silica nanoparticles.

[0049] Step 3: Dissolve 200 mg of vinyl silica nanoparticles, 10 mg of photoinitiator, and 1 mL of ionic liquid in 1 mL of butyl acrylate monomer, and place the mixed solution in an ultrasonic disperser for uniform dispersion to obtain a precursor solution.

[0050] Step 4: Pour the precursor solution into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com