Preparation and application of Tb-MOF nanosheets based on pyrene tetracarboxylic acid

A pyrene tetracarboxylic acid and nanosheet technology is applied in the field of pyrene tetracarboxylic acid-based Tb-MOF nanosheets and their preparation, which can solve problems such as adverse effects on the environment, and achieve increased direct contact area, simple operation, and easy access. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

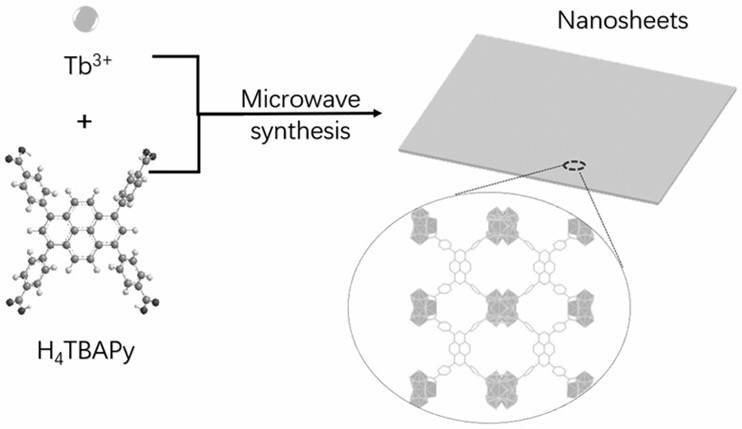

[0032] Such as figure 1 Shown, the preparation method of the Tb-MOF nanosheet based on pyrene tetracarboxylic acid of the present invention, it comprises the steps:

[0033] 1) Dissolve 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene, terbium acetate hexahydrate or terbium nitrate hexahydrate at a molar ratio of 1:3 in an equal volume of N,N-dimethyl 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene solution and terbium acetate or terbium nitrate solution were obtained by ultrasonication at 100 Hz until it was completely dissolved in acetamide;

[0034] 2) Mix equal volumes of 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene solution, terbium acetate solution or terbium nitrate solution obtained in step 1) in a glass bottle, add acid to adjust, and then 100Hz ultrasonic for 10min It is well mixed;

[0035] 3) Put the mixed glass bottle into a microwave oven, react at 400-500W for 5-10min, cool to room temperature, collect the precipitate after centrifugation at 10000r / min, and wash twice with N,N-dime...

Embodiment 1

[0041] (a) Dissolve 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene (20.54 mg, 0.03 mmol) and terbium acetate hexahydrate (31.25 mg, 0.09 mmol) in 5 mL of N,N-di In methyl acetamide, sonicate at 100 Hz for ten minutes until it is completely dissolved to obtain 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene solution and terbium acetate solution;

[0042](b) Mix 100 µL each of the obtained 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene solution and terbium acetate solution in a 3 mL glass bottle, dilute to 1 mL, and then add 5 µL (0.09 mmol) acetic acid , 10min ultrasonic at 100Hz to mix it evenly;

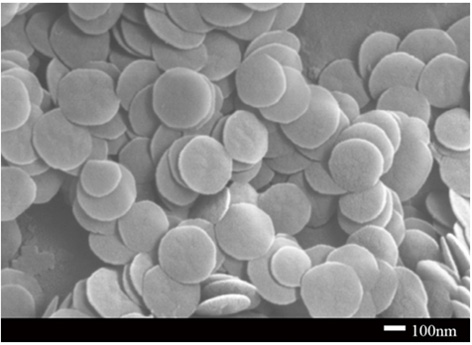

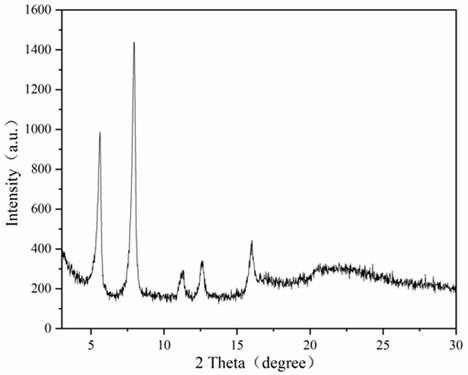

[0043] (c) Put the glass bottle in a microwave oven, react at 400W for five minutes, cool to room temperature, centrifuge at 10,000r / min to collect the precipitate, wash twice with N,N-dimethylacetamide and ethanol, then disperse in water and place in Freeze-drying in a freeze dryer for 24 h yielded 0.38 mg of Tb-MOF nanosheets, and the yield of the obtained nanosheets was 92% (compared to the ligand). ...

Embodiment 2

[0046] (a) Dissolve 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene (20.54 mg, 0.03 mmol) and terbium acetate hexahydrate (31.86 mg, 0.09 mmol) in 5 mL of N,N-di In methyl acetamide, sonicate at 100 Hz for ten minutes until it is completely dissolved to obtain 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene solution and terbium acetate solution;

[0047] (b) Mix 100 µL each of the obtained 1,3,6,8-tetrakis(4-carboxyphenyl)pyrene solution and terbium acetate solution in a 3 mL glass bottle, dilute to 1 mL, and directly sonicate at 100 Hz without adding acid 10min to mix it evenly;

[0048] (c) Put the glass bottle in a microwave oven, react at 400W for five minutes, cool to room temperature, centrifuge at 10,000r / min to collect the precipitate, wash twice with N,N-dimethylacetamide and ethanol, then disperse in water and place in Freeze-drying in a freeze dryer for 24 h yielded 0.37 mg of Tb-MOF nanosheets, and the yield of the obtained nanosheets was 90% (compared to the ligand).

[0049] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com