A kind of sol-gel preparation bi 2 moo 6 /A method of halloysite composite photocatalytic material

A composite photocatalysis and sol-gel technology, which is applied in the field of development and preparation of porous mineral composite photocatalytic materials, can solve the problems of high consumption of alkaline materials, pollution of alkaline wastewater, poor response to visible light, etc., and achieve less equipment requirements and easy operation , Ease of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 0.5821g Bi(NO 3 ) 3 ·5H 2 O, 0.931g halloysite nanotubes, 1g ethylene glycol and 8.73g absolute ethanol were ultrasonically stirred and mixed to obtain a mixture A;

[0028] (2) Weigh 1.1642g tartaric acid, 0.1054g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 8.73g deionized water to obtain solution B;

[0029] (3) Slowly add the solution B obtained in step (2) to the suspension A obtained in step (1), stir for 10 minutes to obtain the mixed solution C, and then place it in a 97°C water bath and stir for 8 hours to generate sol D;

[0030] (4) Put the sol D obtained in step (3) in a drying oven at 130°C for 18 hours, and then calcined in a muffle furnace at 600°C for 3 hours to obtain Bi 2 MoO 6 / Halloysite composite photocatalytic material.

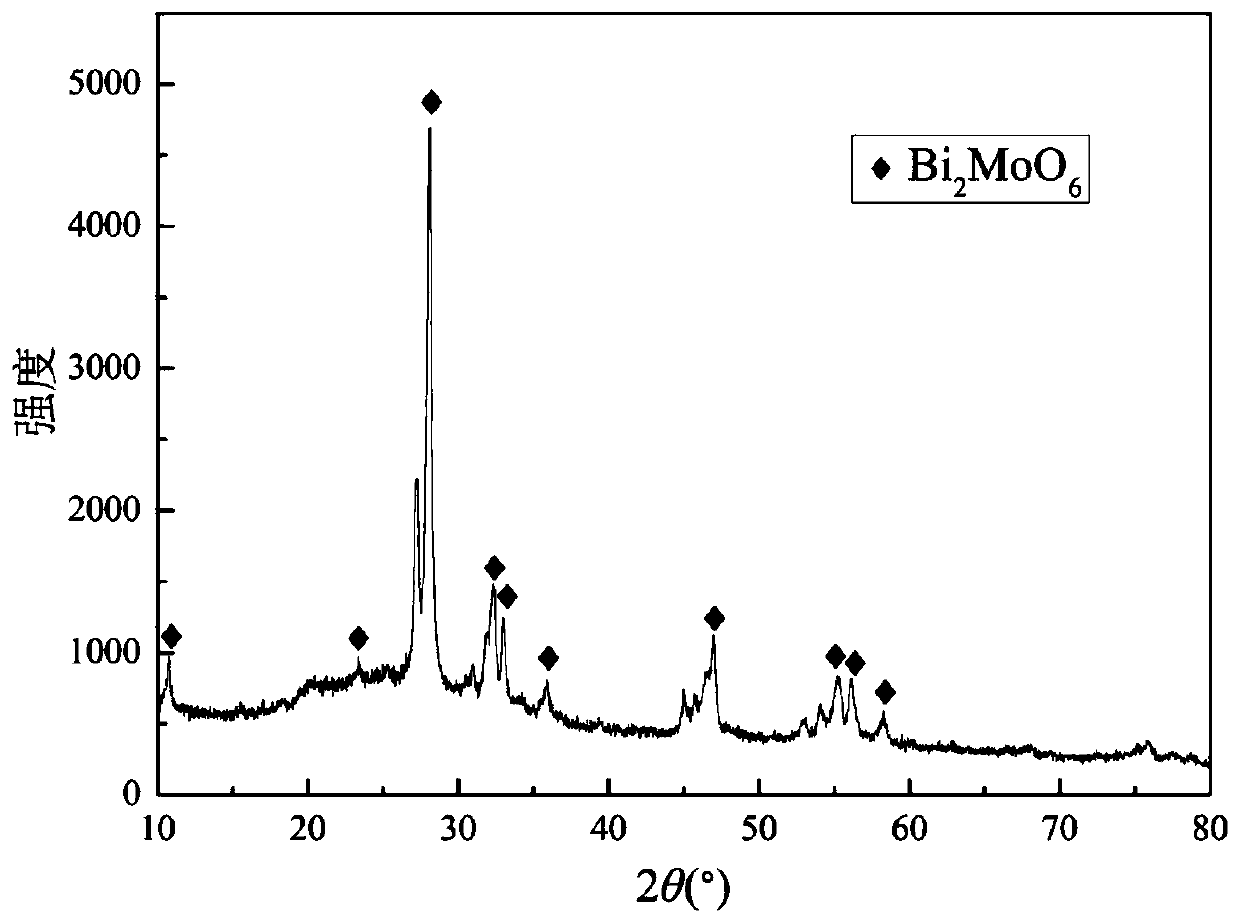

[0031] combine figure 1 It can be seen that the Bi in the composite material 2 MoO 6 Good crystallinity.

Embodiment 2

[0033] (1) Weigh 0.7762g Bi(NO 3 ) 3 ·5H 2 O, 1g halloysite nanotubes, 0.831g ethylene glycol and 14g absolute ethanol are ultrasonically stirred and mixed to obtain a mixture A;

[0034] (2) Weigh 0.7762g tartaric acid, 0.1397g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 7.762g deionized water to obtain solution B;

[0035] (3) Slowly add the solution B obtained in step (2) to the suspension A obtained in step (1), stir for 30 minutes to obtain a mixed solution C, and then place it in a water bath at 90°C and stir for 5 hours to generate sol D;

[0036] (4) After drying the sol D obtained in step (3) in a 130°C drying oven for 10h, and then calcining in a muffle furnace at 400°C for 3h, Bi 2 MoO 6 / Halloysite composite photocatalytic material.

Embodiment 3

[0038] (1) Weigh 0.9832g Bi(NO 3 ) 3 ·5H 2 O, 1.31g halloysite nanotubes, 1.573g ethylene glycol and 16.5g absolute ethanol were ultrasonically stirred and mixed to obtain a mixture A;

[0039] (2) Weigh 1.47g tartaric acid, 0.178g (NH 4 ) 6 Mo 7 o 24 4H 2O was dissolved in 11.8g deionized water to obtain solution B;

[0040] (3) Slowly add the solution B obtained in step (2) to the suspension A obtained in step (1), stir for 15 minutes to obtain a mixed solution C, and then place it in a water bath at 95°C and stir for 7 hours to generate sol D;

[0041] (4) Dry the sol D obtained in step (3) in a 130°C drying oven for 12 hours, and then calcinate in a muffle furnace at 500°C for 2 hours to obtain Bi 2 MoO 6 / Halloysite composite photocatalytic material.

[0042] Performance test experiment:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com