Industrial equipment waste gas circulating treatment equipment

A waste gas circulation and treatment equipment technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve environmental impacts, affect human physical and mental health and other problems, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

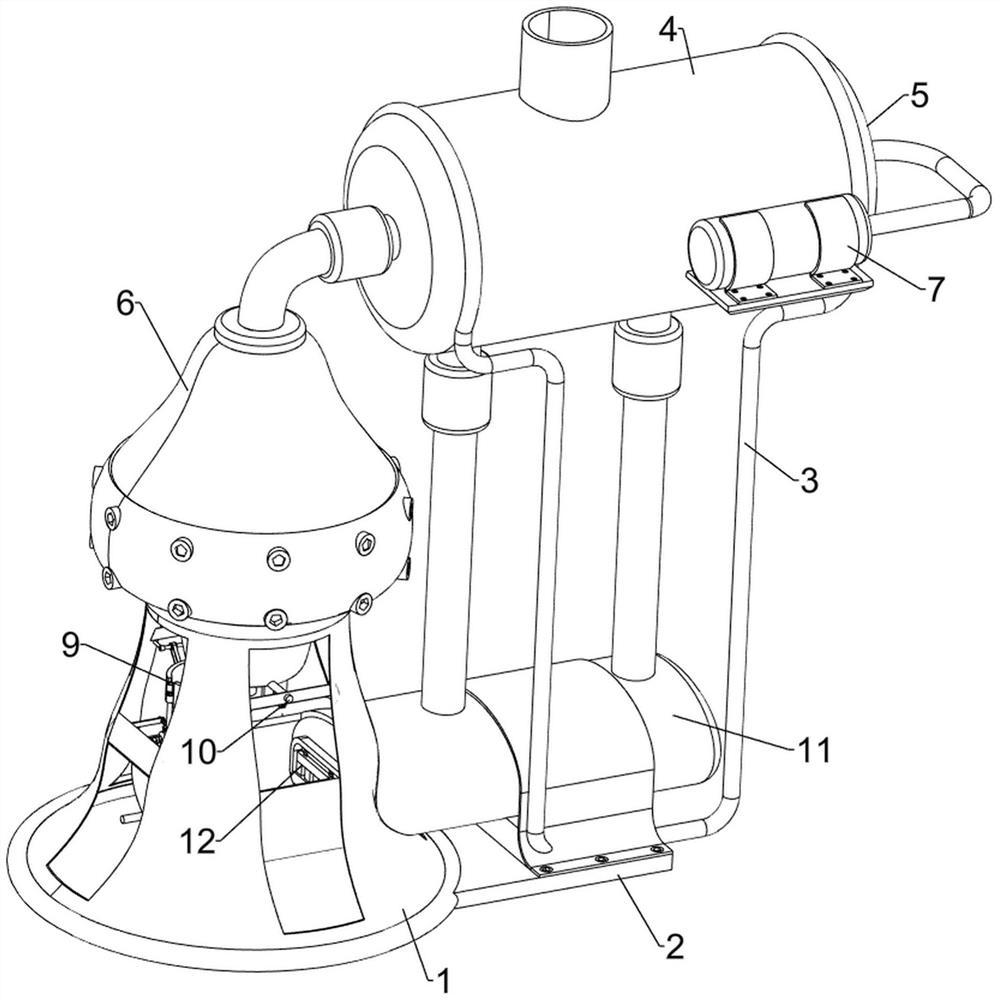

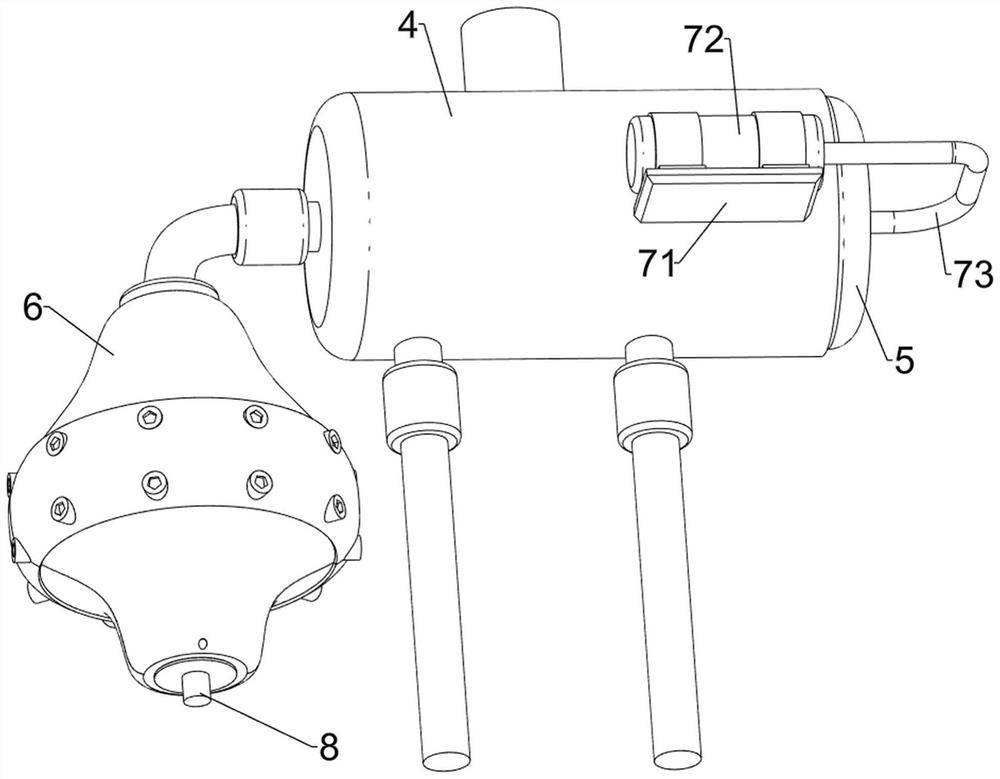

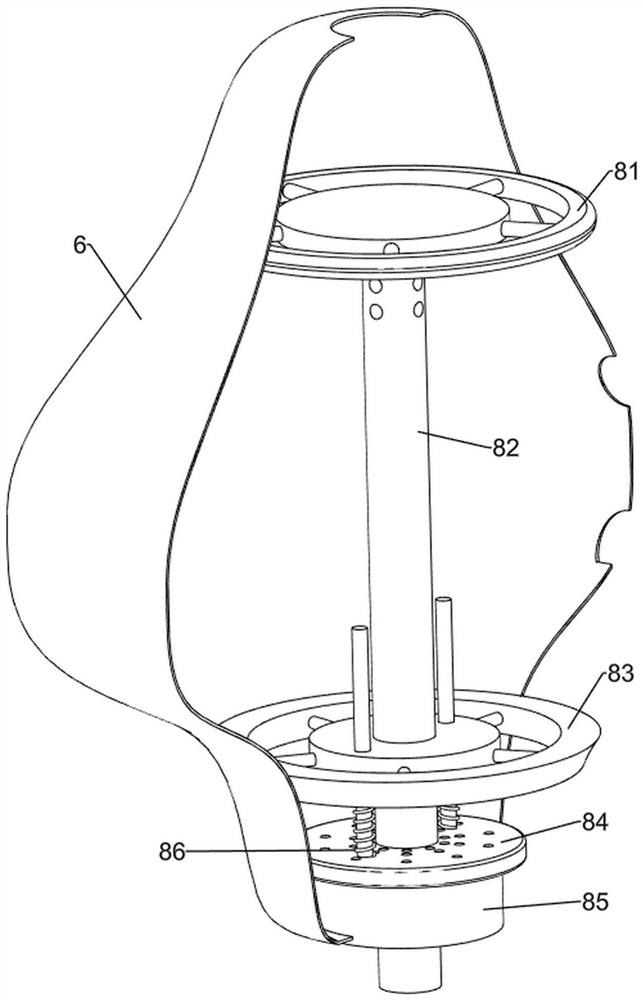

[0036] A kind of industrial equipment exhaust gas circulation treatment equipment, such as Figure 1-3 As shown, it includes a support frame 1, a bottom plate 2, a support rod 3, an exhaust gas bucket 4, a push plate 5, a liquefaction frame 6, a drive assembly 7 and a cooling assembly 8. The left and right sides are connected with support rods 3, and the upper part of the support rods 3 on both sides is connected with the waste gas barrel 4, and the right side of the waste gas barrel 4 is slidingly connected with the push plate 5, and the upper part of the support frame 1 is connected with the liquefaction frame 6, and the liquefaction frame The top of 6 is connected to the left part of the waste gas barrel 4, a one-way switch is provided between the waste gas barrel 4 and the liquefaction frame 6, the front right part of the waste gas barrel 4 is connected to the driving assembly 7, and the inside of the lower part of the liquefaction frame 6 is connected to the cooling assemb...

Embodiment 2

[0041] On the basis of Example 1, such as figure 1 , Figure 4 with Figure 5 As shown, an extruding assembly 9 is also included, and the extruding assembly 9 includes an arc plate 91, a connecting plate 92, a slider 93, an arc splint 94 and a torsion spring 95, and the right side of the lower part of the liquefaction frame 6 is connected with an arc plate 91, the left side of the middle part of the support frame 1 is connected with a connecting plate 92, the middle part of the connecting plate 92 right side is slidably connected with a slide block 93, and the sliding block 93 top is rotatably connected with two arc splints 94, and the arc splint 94 is connected with the arc The plates 91 cooperate, and a torsion spring 95 is connected between the two arc splints 94 .

[0042]When the sponge block 85 moves downward, the two arc splints 94 move to the right by manually pushing the slide block 93 to the right, and the two arc splints 94 move to the right and contact the arc pl...

Embodiment 3

[0044] On the basis of Example 2, such as figure 1 with Figure 6-Figure 9 As shown, a limit assembly 10 is also included, and the limit assembly 10 includes a second spring 101, a first slide bar 102, a wedge block 103, a third spring 104, a first rack 105, a first rotating shaft 106, a first gear 107, the second rotating shaft 108, the second gear 109, the second slide bar 110 and the second rack 111, the second spring 101 is connected between the slider 93 and the connecting plate 92, and the front and rear sides of the upper part of the connecting plate 92 are sliding The first slide bar 102 is connected, and the inside of the first slide bar 102 on both sides is connected with a wedge block 103. The wedge block 103 on both sides cooperates with the slide block 93, and the wedge block 103 on both sides is connected to the connecting plate 92. There is a third spring 104, the first rack 105 is connected to the outside of the wedge block 103 bottom on both sides, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com