A stack mold side-take tableware packaging system and packaging method

A packaging system and tableware technology, applied in transportation and packaging, household utensils, other household utensils, etc., can solve the problems of difficult product hygiene quality to meet customer needs, difficult product hygiene requirements, high labor intensity, etc., to achieve a simple and reasonable structure , Satisfy product sanitation and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

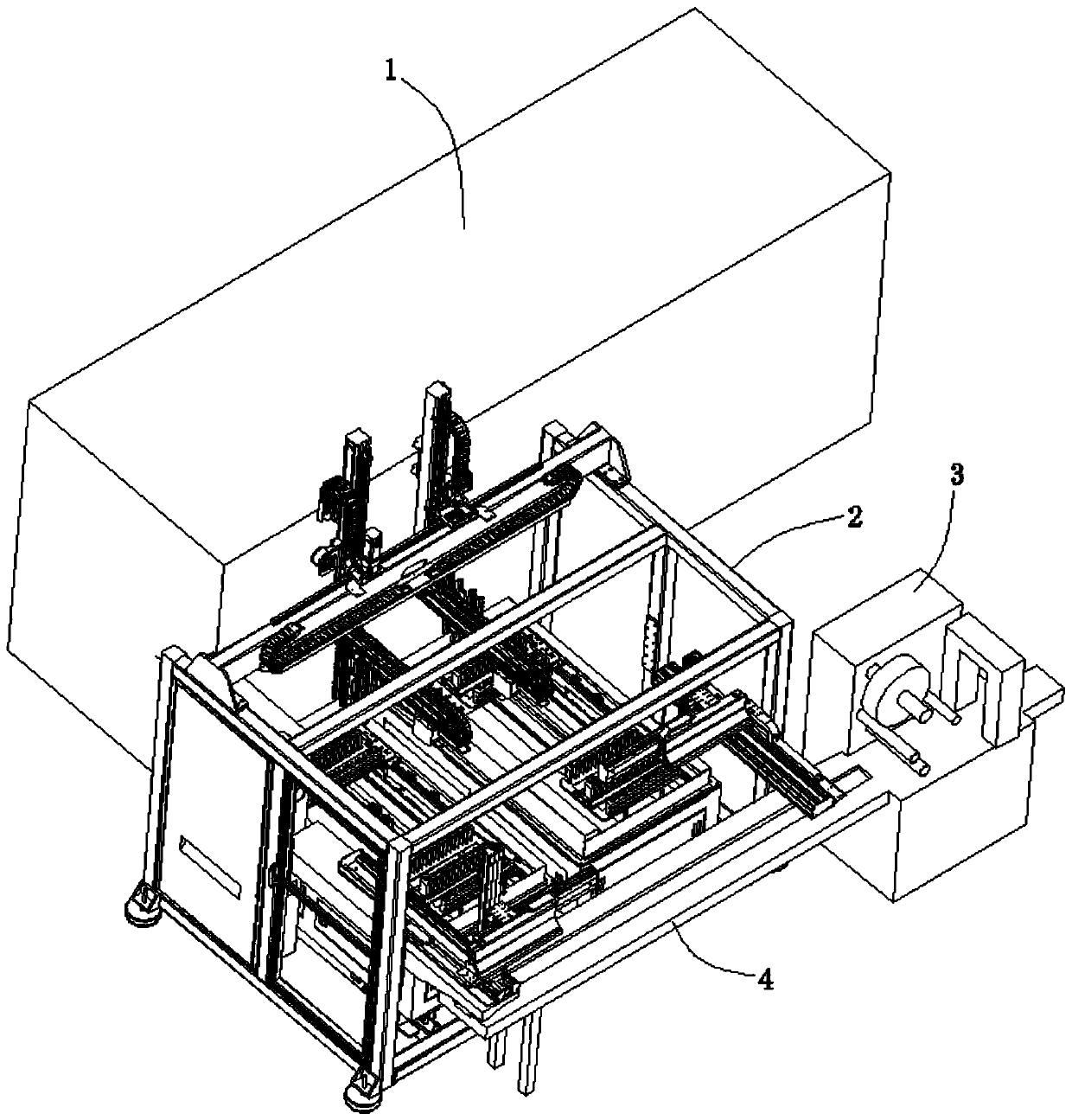

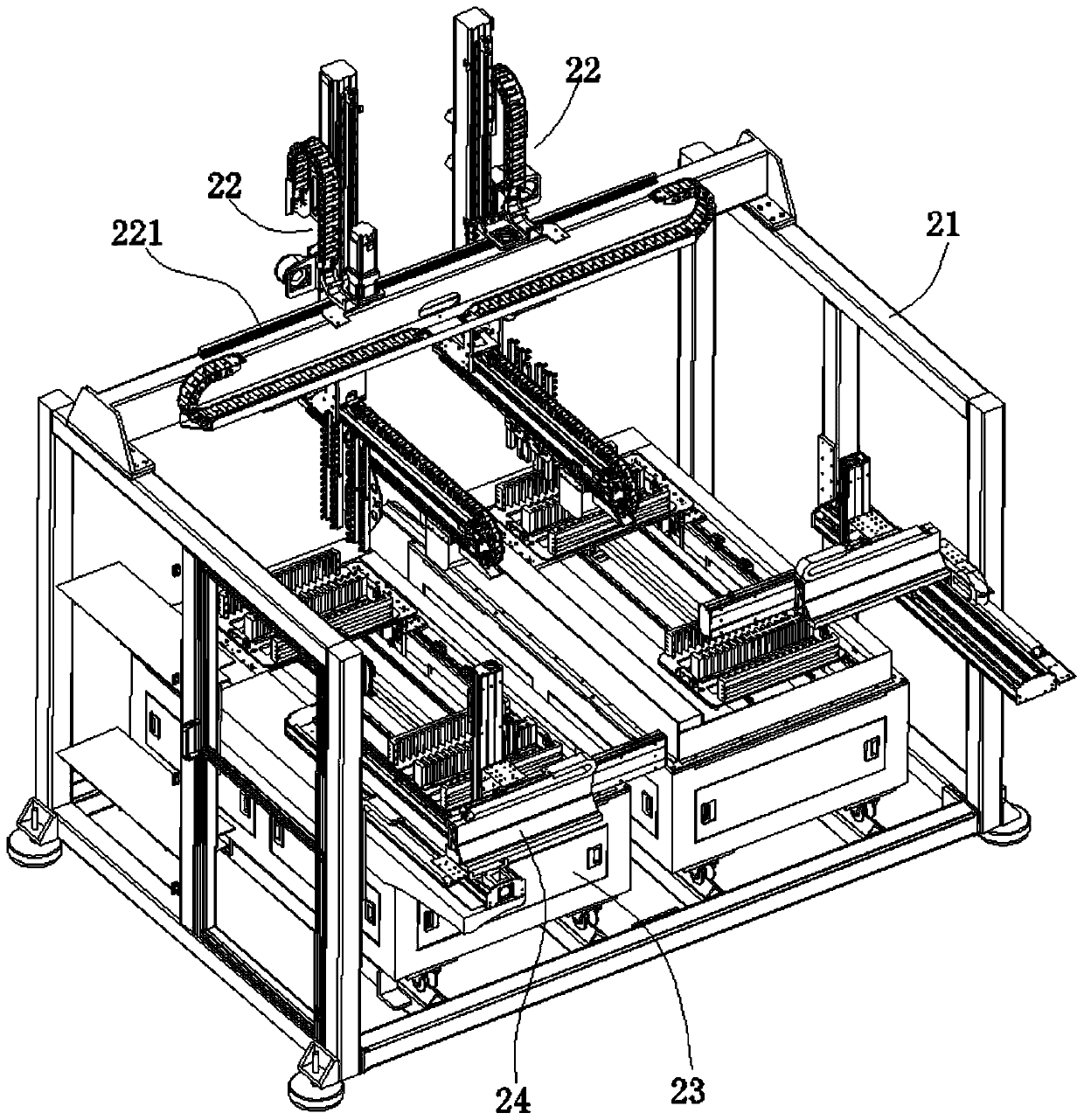

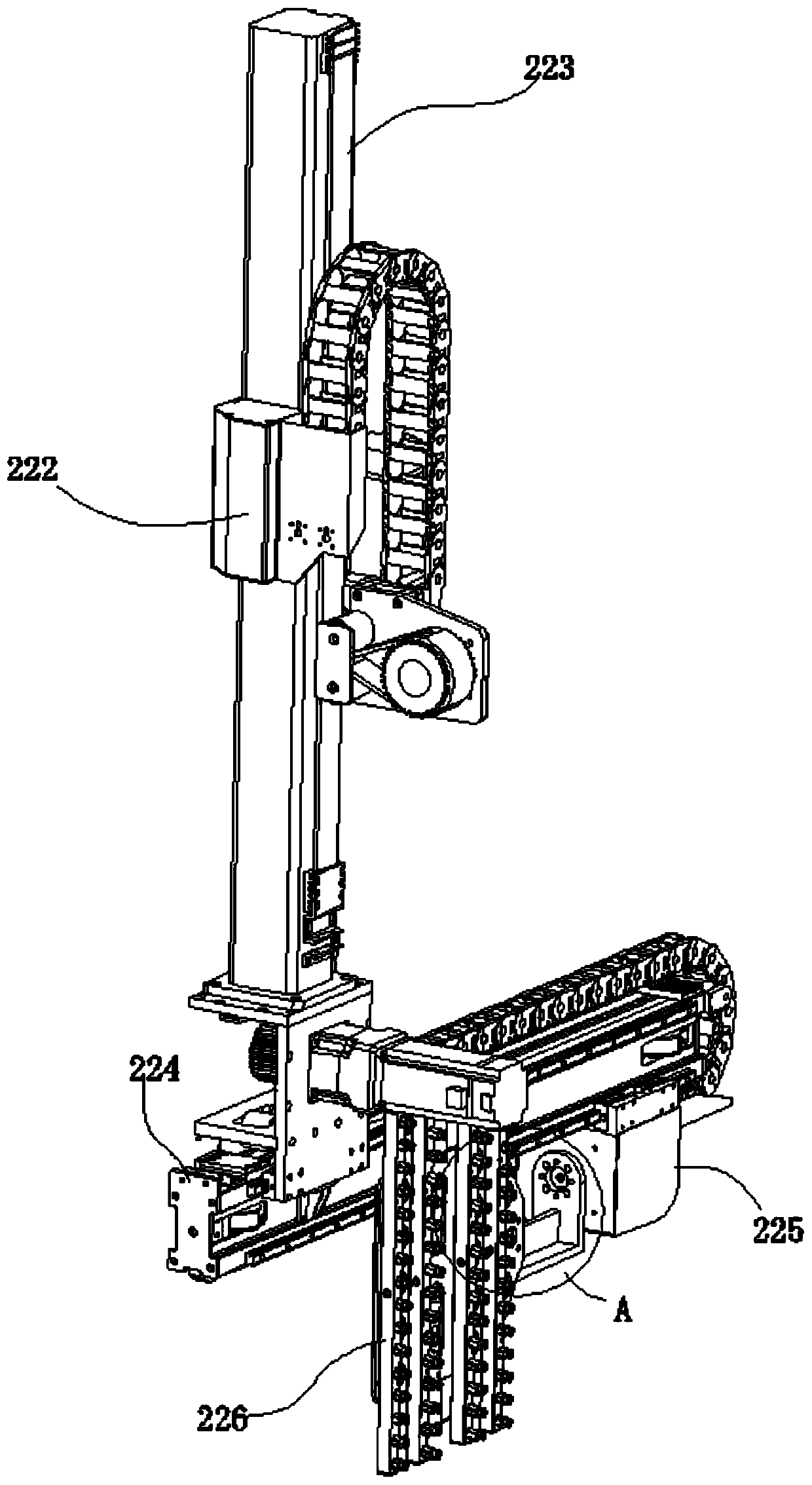

[0032] Example: such as Figure 1 to Figure 6 As shown, a stack mold side-taking tableware packaging system of the present invention includes an injection molding machine 1, a product conveying device 2 and a packaging machine 3 arranged in sequence, and the product conveying device 2 includes a frame 21, on which the frame 21 Corresponding to the mold of the injection molding machine 1, there are several first manipulators 22 for picking up products that can be fed in three axes, and a stacking machine for stacking products is provided in the frame 21 corresponding to the first manipulators 22. Putting machine 23, on the other side of this frame 21, corresponding to this stacking machine 23 is provided with the second manipulator 24 that can be three-axis feeding that is used to pick up the stacked product, between described second manipulator 24 and packaging machine 3 A conveyor belt 4 for conveying the product to the packaging machine 3 is provided in between. In actual p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com