An automatic test device and method for water absorption height of wet curtain products

An automatic test and height technology, applied in measuring devices, optical devices, instruments, etc., can solve the problems of changes in wetting height, inaccurate measurement data, and prolong measurement time, so as to improve accuracy, improve work efficiency, Guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

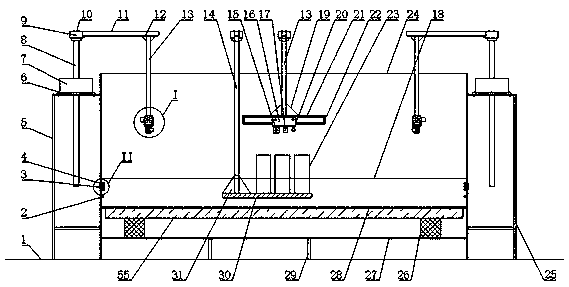

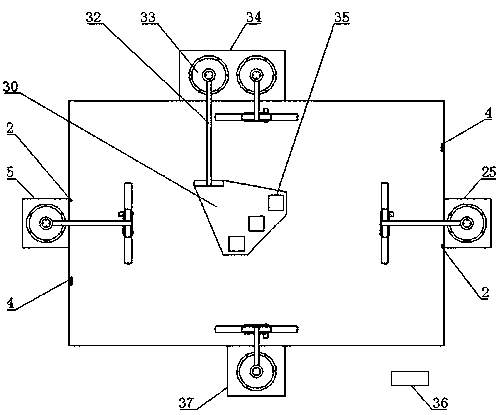

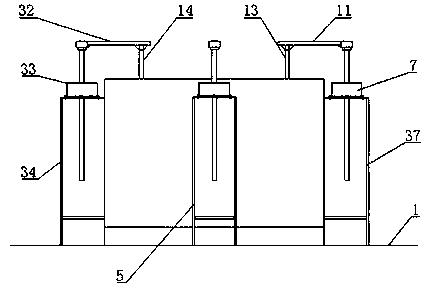

[0032] An automatic water absorption height test device for wet curtain products, mainly composed of a water tank 24, a sample placement device, a sample surveying device and a display PLC controller 36;

[0033]The tank 24 is a cuboid container without a top formed by sealing the first side wall, the second side wall, the third side wall, the fourth side wall and the bottom. The bottom of the tank 24 is provided with support legs 29, and the support legs 29 can be placed with On the ground 1; the bottom of the water tank 24 is provided with a water tank inner bottom plate 28 and a water tank outer bottom plate 27, the water tank inner bottom plate 28 is above the water tank outer bottom plate 27, a cavity is provided between the water tank inner bottom plate 28 and the water tank outer bottom plate 27, and electric heating The body 55 is fixedly installed on the lower surface of the inner bottom plate 28 of the water tank, the electric heating body 55 is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com