Design method of curved-surface acoustic transmission wedge for circumferential ultrasonic detection of small-diameter pipe

A technology of ultrasonic detection and design method, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, design optimization/simulation, etc. Problems such as poor performance, to achieve the effect of improving accuracy, improving accuracy, and avoiding poor coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in further detail below in conjunction with accompanying drawing:

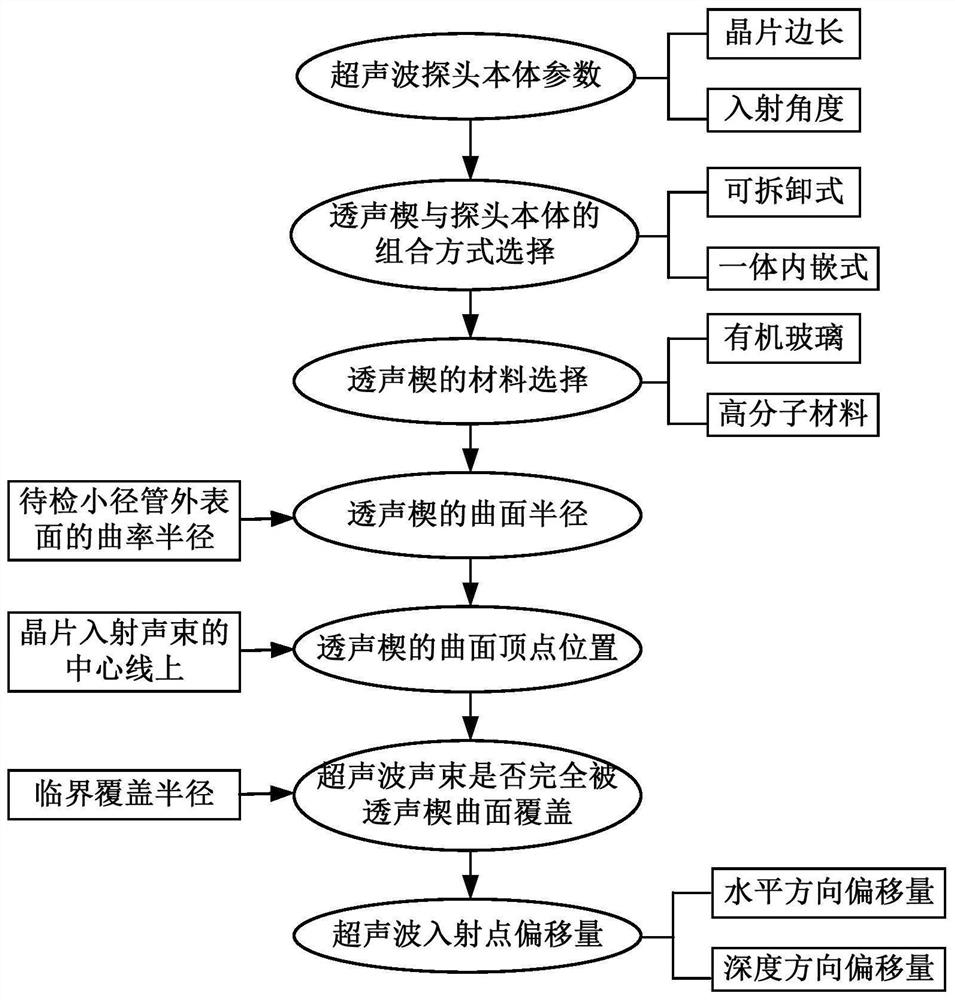

[0039] refer to figure 1 , the design method of the curved surface sound-transmitting wedge for circumferential ultrasonic detection of small-diameter pipes according to the present invention comprises the following steps:

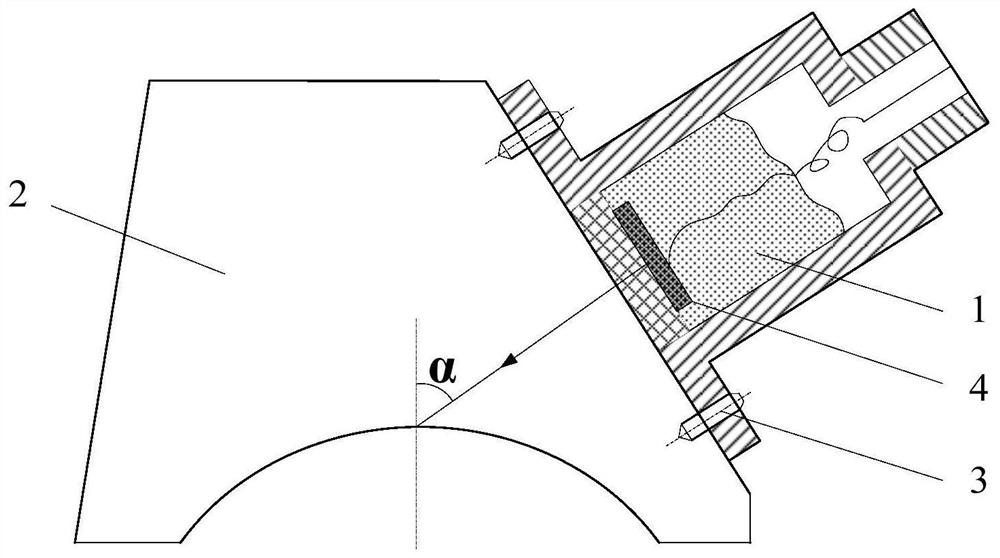

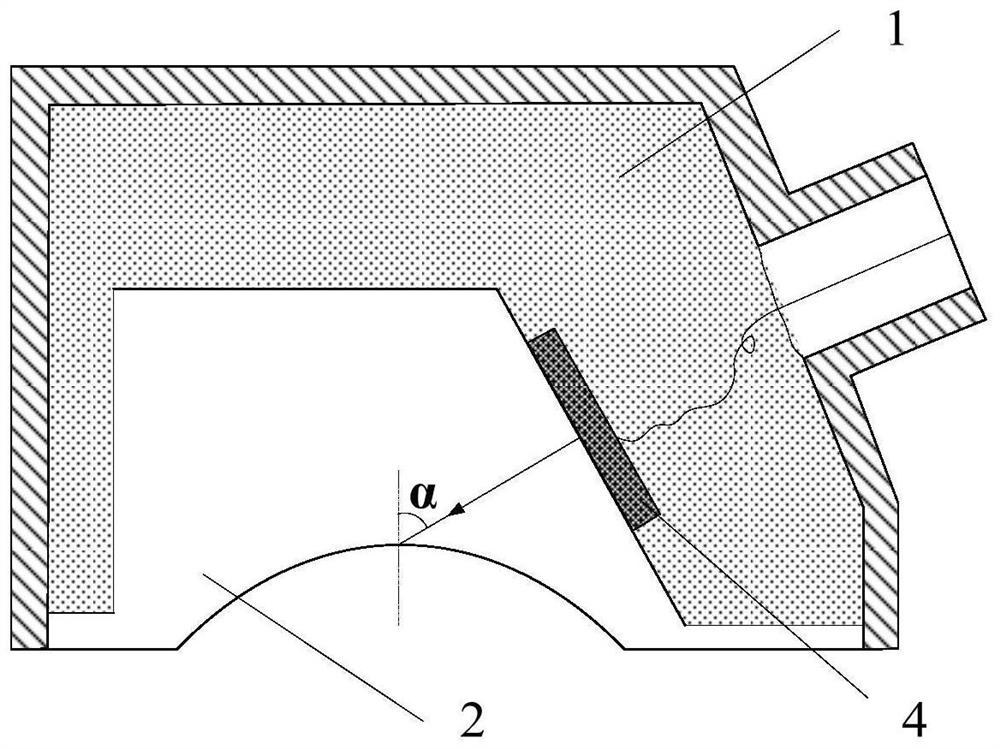

[0040] 1) Determine the parameters of the ultrasonic probe body 1 corresponding to the curved sound-transmitting wedge 2;

[0041] The parameters of the ultrasonic probe body 1 corresponding to the curved sound-transmitting wedge 2 include the side length of the square chip 4 in the ultrasonic probe body 1 and the incident angle of the ultrasonic probe body 1;

[0042] 2) Determine the combination mode of the curved sound-transmitting wedge 2 and the ultrasonic probe body 1;

[0043] The combination of the curved sound-transmitting wedge 2 and the corresponding ultrasonic probe body 1 is a detachable or integrated embedded type, wherein, in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com