Combined type guiding drilling tool and method

A directional drilling and composite technology, applied in directional drilling, drilling equipment and methods, drilling equipment, etc., can solve the problems that the wellbore trajectory is difficult to meet the site requirements, the wellbore buckling, the drilling tool does not rotate, etc., to solve the problem of wellbore Eye extension problem, improved anti-vibration performance, and improved passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

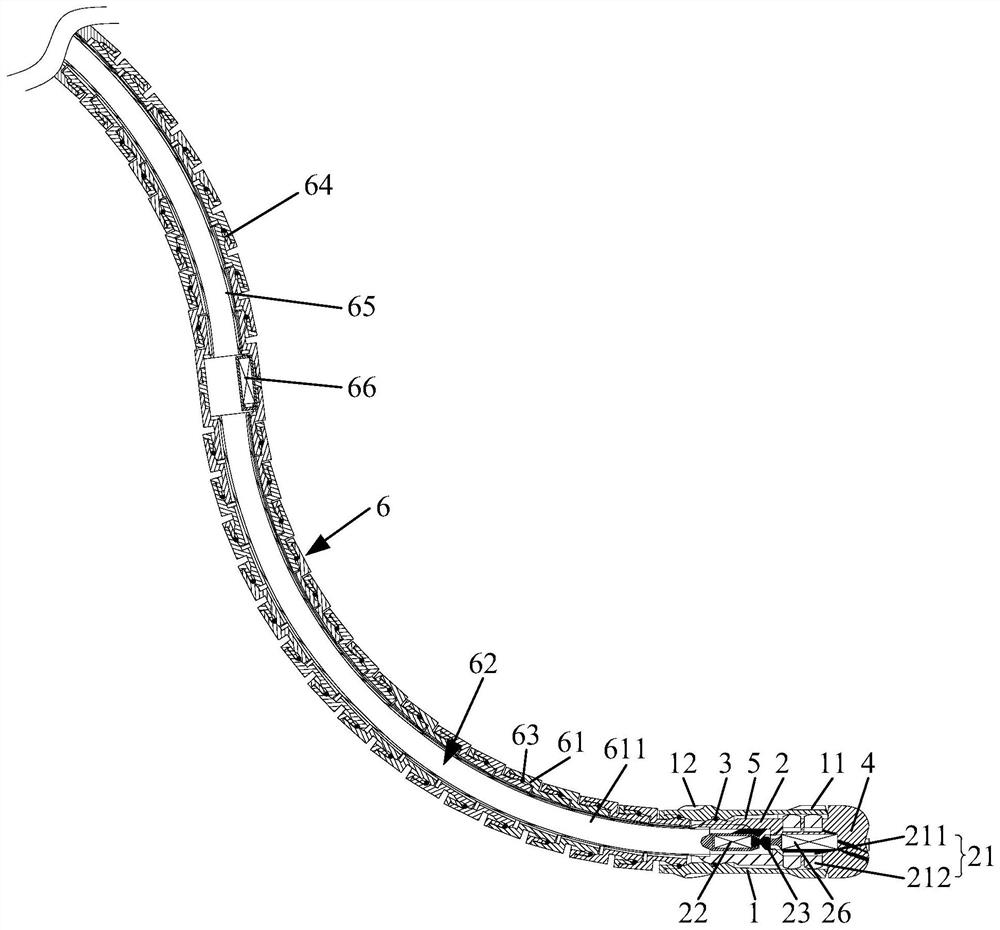

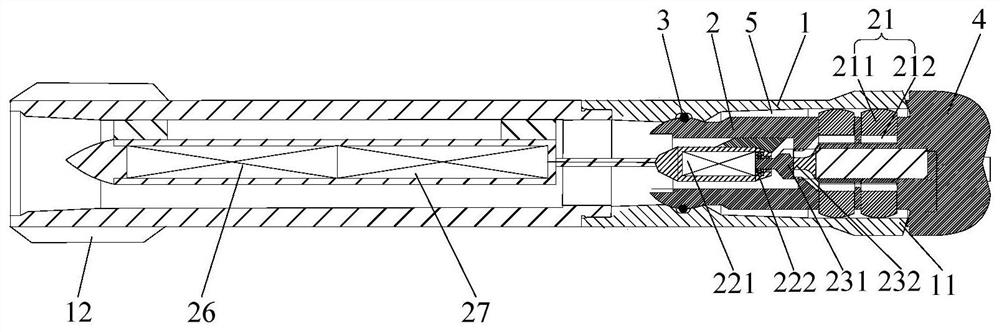

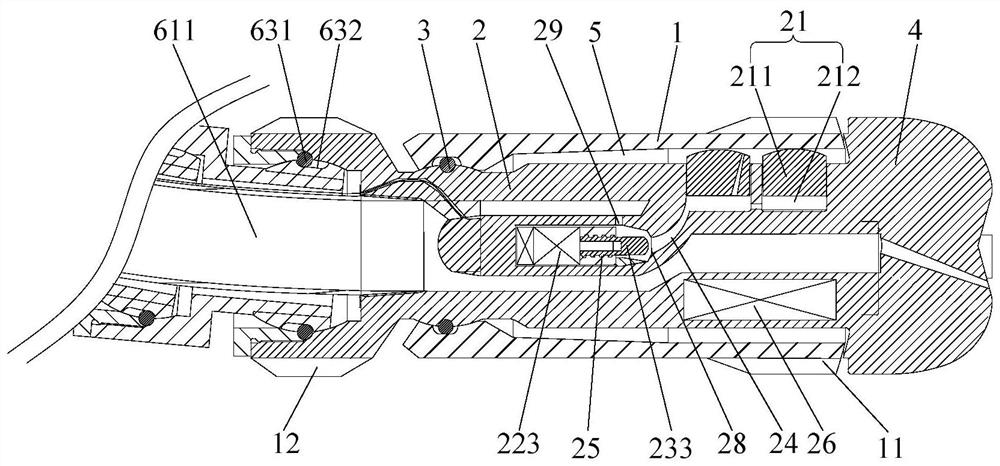

[0049] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. where the use of the adjective or adverbial modifiers "upper" and "lower", "vertical" and "horizontal", "front" and "rear", "top" and "bottom", "inner" and "outer" This is merely to facilitate relative reference between sets of terms and does not describe any particular directional limitation on the modified term. In addition, the terms "first", "second" and so on are only used for descriptive purposes, and cannot be understood as indicating or implying relative importance or implicitly specifying the number of indicated technical features. Therefore, the definition of "first" , "second", etc. may expressly or implicitly include one or more of these features. In the description of the present invention, unless otherwise specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com