Foam mercerizing foaming system as well as preparation method and application thereof

A foam yarn and system technology, applied in textiles and papermaking, improved handle fibers, fiber treatment, etc., can solve the problems of easy foam rupture and poor mercerizing effect, and achieve the goals of saving alkali, good mechanical properties and improving performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

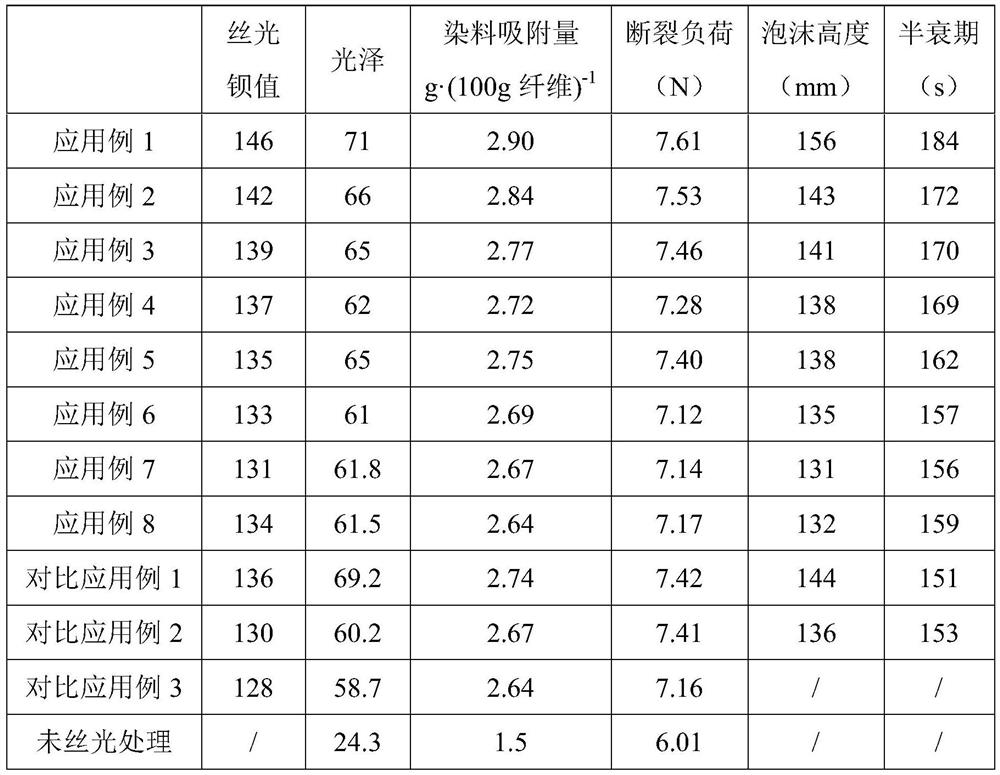

Examples

Embodiment 1

[0060] This embodiment provides a foam mercerizing foaming system and a preparation method thereof. The foam mercerizing foaming system includes the following components in parts by weight: 2 parts of sodium dodecylbenzenesulfonate, 2 parts of sodium isooctyl sulfate , 2 parts of lauryl dimethyl betaine, 2 parts of lauric acid diethanolamide, 1 part of hydrophilic silicone oil softener 1260, 25 parts of sodium hydroxide solution (260g / L) and 66 parts of water.

[0061] The preparation method of above-mentioned foam mercerized foaming system is as follows:

[0062] (1) Mix sodium dodecylbenzene sulfonate, sodium isooctyl sulfate, dodecyl dimethyl betaine, lauric acid diethanolamide, hydrophilic silicone oil softener 1260, sodium hydroxide solution and water evenly After that, the mixed solution is obtained;

[0063] (2) The mixed solution obtained in step (1) is passed through a net-type static foamer, and after stirring for 3 minutes at a stirring speed of 450rpm, the stirrin...

Embodiment 2

[0065] This embodiment provides a foam mercerizing foaming system and a preparation method thereof. The foam mercerizing foaming system includes the following components in parts by weight: 1 part of anionic surfactant, 0.5 part of nonionic surfactant, zwitterionic surfactant 0.5 parts of active agent, 2.5 parts of lauryl dimethyl amine oxide, 1.5 parts of silicone softener T875, 20 parts of sodium hydroxide solution (260g / L) and 74 parts of water.

[0066] The preparation method of above-mentioned foam mercerized foaming system is as follows:

[0067] (1) Mix anionic surfactant, nonionic surfactant, zwitterionic surfactant, lauryl dimethyl amine oxide, silicone softener T875, sodium hydroxide solution and water to obtain a mixed solution ;

[0068] (2) The mixed solution obtained in step (1) is passed through a net-type static foamer, and after stirring for 3 minutes at a stirring speed of 300rpm, the stirring speed is increased to 1500rpm for foaming to obtain a foaming rat...

Embodiment 3

[0070] This embodiment provides a foam mercerizing foaming system and a preparation method thereof. The foam mercerizing foaming system includes the following components in parts by weight: 1 part of anionic surfactant, 2 parts of nonionic surfactant, zwitterionic surfactant 1 part of active agent, 3 parts of lauryl dimethyl amine oxide, 2 parts of silicone softener T875, 29 parts of sodium hydroxide solution (280g / L) and 60 parts of water.

[0071] The preparation method of above-mentioned foam mercerized foaming system is as follows:

[0072] (1) Mix anionic surfactant, nonionic surfactant, zwitterionic surfactant, lauryl dimethyl amine oxide, silicone softener T875, sodium hydroxide solution and water to obtain a mixed solution ;

[0073] (2) The mixed solution obtained in step (1) is passed through a radial dynamic foamer, and after stirring for 2min at a stirring speed of 500rpm, the stirring speed is increased to 2500rpm for foaming to obtain a foaming ratio of 6:1. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com