A Dispersed Printing Process for Woven Fabrics

A printing process and dispersion technology, which is applied in the field of printing and dyeing, can solve the problems of shrinkage of fabrics, irregular changes of printing patterns, and lower printing quality, so as to reduce damage, ensure printing effect, and ensure printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

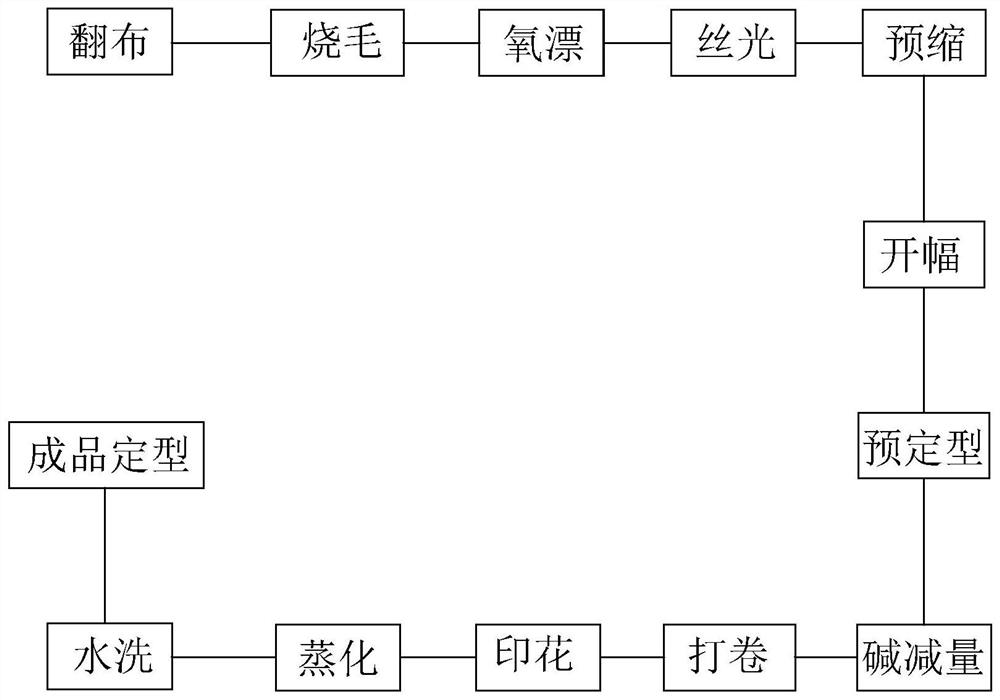

[0045] Embodiment 1: a kind of woven cloth dispersion printing technique, as figure 1 The woven cotton fabric shown was treated as follows:

[0046] A. Turn over the cloth, turn the accepted cloth into the cloth cart, and each cloth pulls out 2-3 meters of cloth head for jointing;

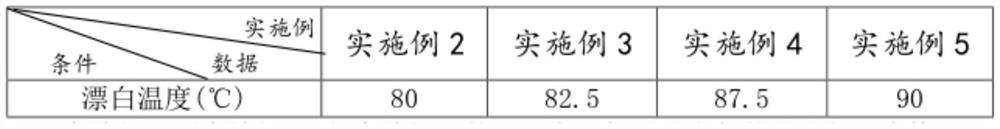

[0047] K. Singeing, use the singeing machine to singe the cloth, burn off the hair on the surface of the cloth, and bleach the cloth after the singeing is completed. The bleaching process is to immerse the cloth in oxygen-containing bleaching agent, and the bleaching temperature is controlled. At 85°C, the bleaching time is 15 minutes; oxygen-containing bleaching agents include hydrogen peroxide, color bleaching powder, and oxygen bleaching stabilizers, and oxygen bleaching stabilizers include 8 parts of magnesium sulfate, 5 parts of aminoethanol phosphoric acid, 5 parts of picolinic acid, and 2 parts EDTA complexing agent; after the cloth is bleached, it needs to be soaked in caustic soda solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com