Edge anticorrosive electrophoretic coating composition, preparation method and application

A technology of electrophoretic coatings and compositions, applied in anti-corrosion coatings, electrophoretic coatings, polyurea/polyurethane coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

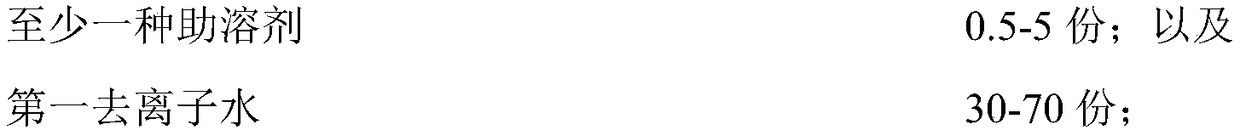

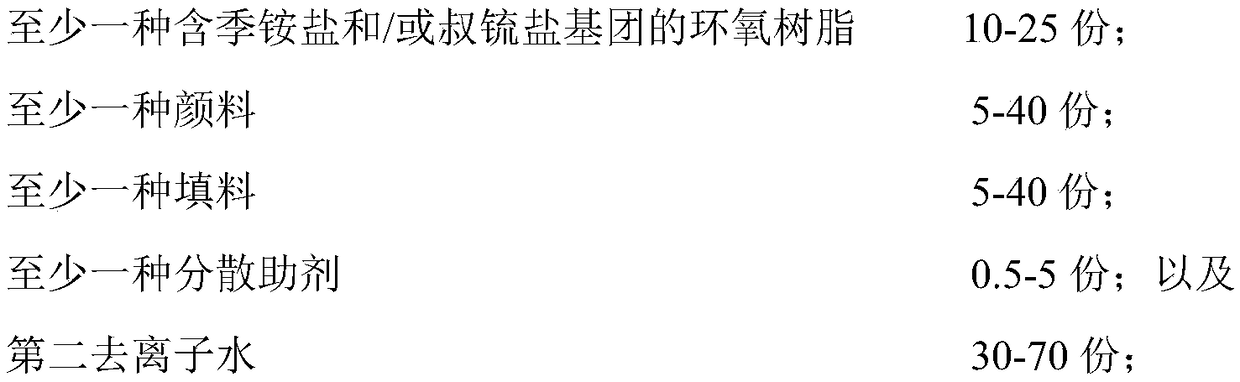

Method used

Image

Examples

Embodiment 1

[0107] Embodiment 1 prepares organic amine modified epoxy resin

[0108] Add 1850 parts of bisphenol A type epoxy resin (epoxy equivalent EEW=185), 868 parts of bisphenol A and 450 parts of methyliso butyl ketone. After the addition, the temperature of the reaction system was raised to 120°C. After the raw materials were completely dissolved and mixed uniformly, 3.7 parts of triphenylphosphine was added, and then the temperature of the reaction system was raised to 145°C. The reaction was continued at this temperature for 2 h, and when the epoxy equivalent of the reaction system reached the theoretical value (EEW=1140), the heating was stopped. When the reaction system was cooled to 90°C, 139 parts of N-methylethanolamine and 143 parts of ketimine (prepared by the reaction of diethylenetriamine and methyl isobutyl ketone in a molar ratio of 1:2 were added successively, the final product The solid content is 100%), the temperature of the reaction system was raised to 120°C ag...

Embodiment 2

[0109] Embodiment 2 prepares organic amine modified epoxy resin

[0110] Add 1850 parts of bisphenol A type epoxy resin (epoxy equivalent EEW=185), 741 parts of bisphenol A, 84 parts of adipic acid in the 5L reactor equipped with stirrer, thermometer, nitrogen conduit and reflux condenser and 435 parts of methyl isobutyl ketone. After the feeding is complete, the temperature of the reaction system is raised to 120°C. After the raw materials are completely dissolved and mixed uniformly, 3 parts of triphenylphosphine are added, and then the temperature of the reaction system is raised to 145°C. The reaction was continued at this temperature for 2 h, and when the epoxy equivalent of the reaction system reached the theoretical value (EEW=1140), the heating was stopped. When the reaction system was cooled to 90°C, 139 parts of N-methylethanolamine and 143 parts of ketimine (prepared by the reaction of diethylenetriamine and methyl isobutyl ketone in a molar ratio of 1:2 were added...

Embodiment 3

[0111] Embodiment 3 prepares organic amine modified epoxy resin

[0112]Add 2000 parts of bisphenol S type epoxy resin (epoxy equivalent EEW=200), 887 parts of bisphenol A and 550 parts of methyliso butyl ketone. After the feeding is complete, the temperature of the reaction system is raised to 120°C. After the raw materials are completely dissolved and mixed uniformly, 4 parts of triphenylphosphine are added, and then the temperature of the reaction system is raised to 145°C. The reaction was continued at this temperature for 2 h, and when the epoxy equivalent of the reaction system reached the theoretical value (EEW=1300), the heating was stopped. When the reaction system was cooled to 90°C, 125 parts of N-methylethanolamine and 150 parts of ketimine (prepared by the reaction of diethylenetriamine and methyl isobutyl ketone in a molar ratio of 1:2, the final product The solid content is 100%), the temperature of the reaction system was raised to 120°C again, and the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com