Preparation of ball warp mercerizing process and high-efficiency mercerizing penetrant in the production of denim fabric

A technology of mercerizing penetrating agent and denim fabric, which is applied in the direction of mercerizing of yarn/thread/filament, plant fiber, fiber treatment, etc. It can solve the problem of unsatisfactory gloss and softness of fabrics, increased discharge of colored wastewater, and impact on denim Fabric quality and other issues, to achieve good mercerizing effect, increase added value, save dyes and auxiliaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The 16s cotton / tencel 70 / 30 yarn is wound on the warp beam through warping, and a certain tension is applied to the yarn on the warp beam to form a bundle yarn. Each bundle yarn contains 400-500 yarns. Each bundle of yarn is wound on a warp beam to prepare a ball warp. The bundle yarns on 12-25 ball warps are arranged as a whole and fed into the guide roller at the same time. The ball warp is directly mercerized and then the warp beam is dyed. Process, after multiple oxidation processes, the ball is finally dyed.

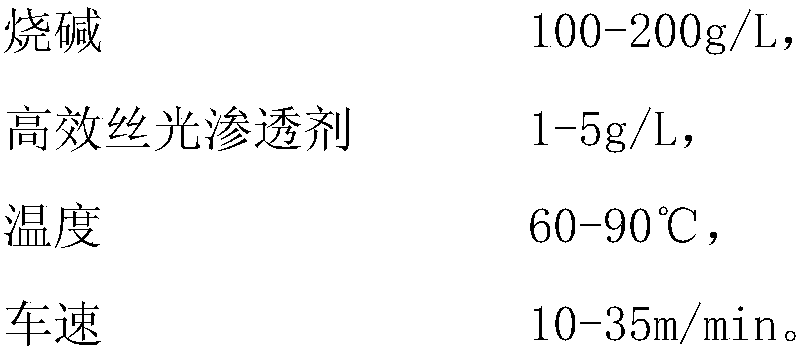

[0030] The ball warp mercerizing process formula in the above scheme is:

[0031]

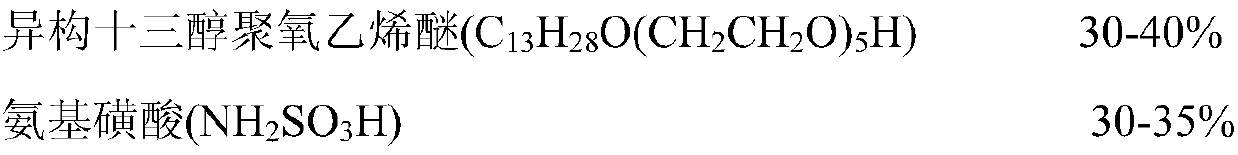

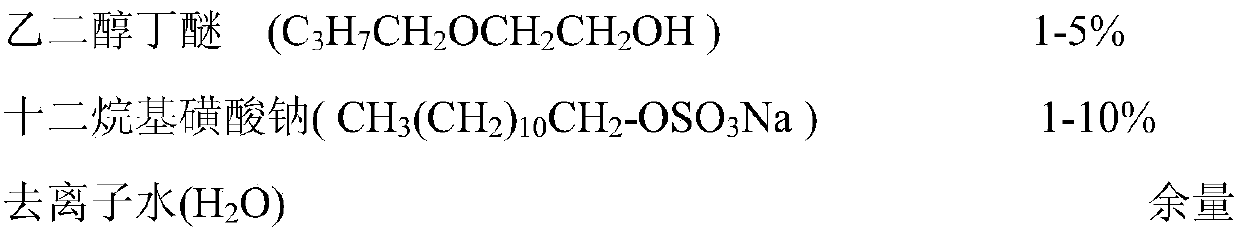

[0032] The preparation method of the high-efficiency mercerizing penetrant in the above scheme is:

[0033] Accurately weigh 30g of isotridecyl alcohol polyoxyethylene ether and place it in a completely dry three-necked flask with a thermometer; install the stirring device, start the stirrer, the stirring degree is 800r / min, and start to heat up to 100 after evenly stirring -160℃, ...

Embodiment 2

[0042] The 12s cotton / viscose 80 / 20 yarn is wound on the warp beam through warping, and the yarn on the warp beam is applied with a certain tension to form a bundle yarn. Each bundle yarn contains 400-500 yarns. Each bundle of yarn is wound on a warp beam to prepare a ball warp. The bundle yarns on 12-25 ball warps are arranged as a whole and fed into the guide roller at the same time. The ball warp is directly mercerized and then the warp beam is dyed. Process, after multiple oxidation processes, the ball is finally dyed.

[0043] The ball warp mercerizing process formula in the above scheme is:

[0044]

[0045] The preparation method of the high-efficiency mercerizing penetrant in the above scheme is:

[0046] Accurately weigh 36g of isomerized tridecanol polyoxyethylene ether and place it in a completely dry three-necked flask with a thermometer; install the stirring device, start the stirrer, the stirring degree is 800r / min, and start to heat up to 100 after evenly stirring -1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com