Anti-radiation ceramic tile adhesive mortar and preparation method thereof

A bonding mortar and anti-radiation technology, which is applied in the field of ceramic tile bonding mortar production, can solve problems such as not having radiation protection performance, and achieve the effects of excellent radiation protection performance, excellent adhesion, and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

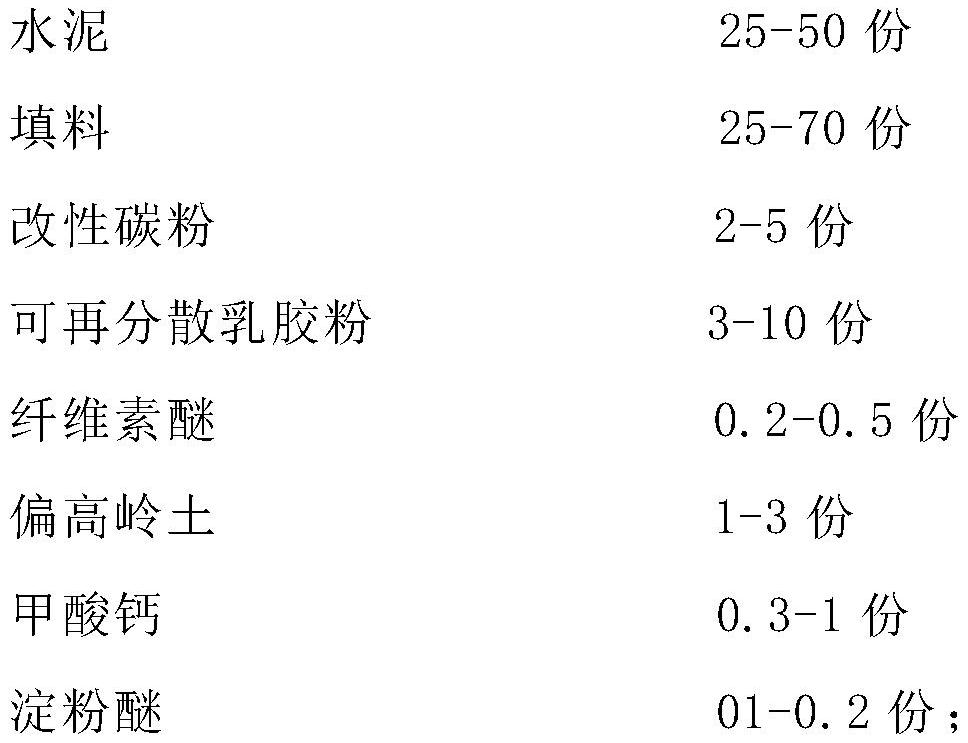

[0027] A kind of anti-radiation ceramic tile bonding mortar according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0028]

[0029] Wherein, the filler includes 15 parts of 40-70 mesh barium sulfate sand and 40 parts of 50-100 mesh quartz sand.

[0030] The preparation method of the radiation-proof ceramic tile bonding mortar mainly includes the following steps carried out in sequence:

[0031] (1) Put the cement into the stirring tank, turn on the stirring blade and the flying knife, the rotating speed of the main shaft stirring blade is 200r / min, and the rotating speed of the flying knife is 3000r / min, and then slowly add the high-grade material into the stirring tank while stirring. Then disperse the latex powder, cellulose ether, calcium formate and starch ether, and stir for 5 minutes;

[0032] (2) Keep the rotating speed of the main shaft stirring blade at 200r / min, and the rotating...

Embodiment 2

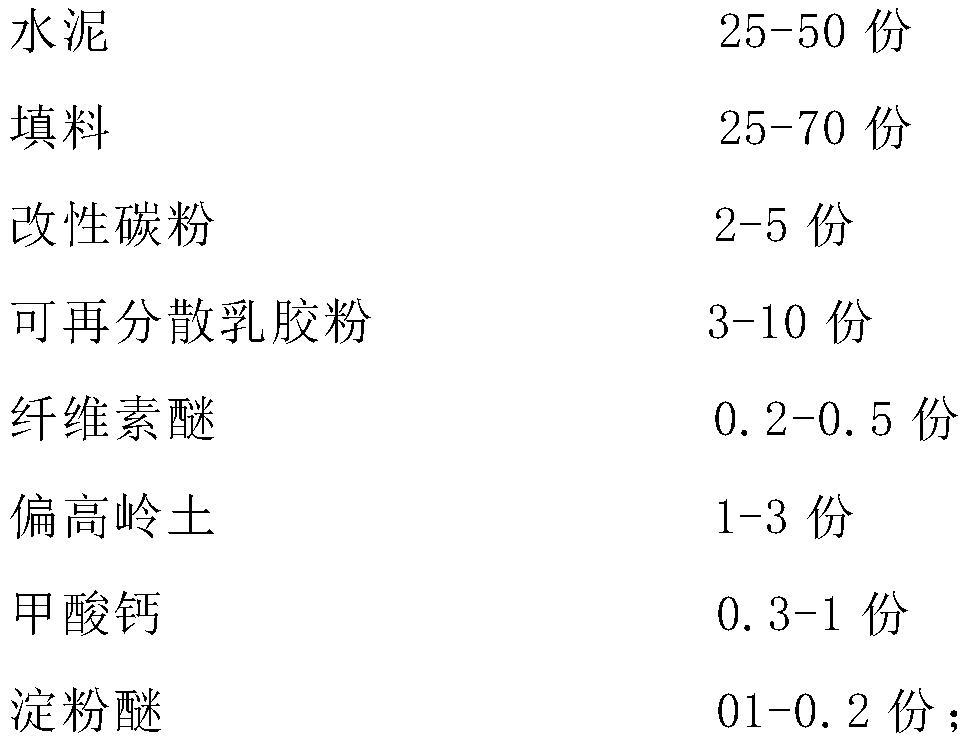

[0034] A kind of anti-radiation ceramic tile bonding mortar according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0035]

[0036]

[0037] Wherein, the filler includes 15 parts of 40-70 mesh barium sulfate sand and 10 parts of other graded sands except barium sulfate sand.

[0038] The preparation method of the radiation-proof ceramic tile bonding mortar mainly includes the following steps carried out in sequence:

[0039] (1) Put the cement into the stirring tank, turn on the stirring blade and the flying knife, the rotating speed of the main shaft stirring blade is 240r / min, and the rotating speed of the flying knife is 2500r / min, and then slowly add the high-grade material into the stirring tank while stirring. Then disperse the latex powder, cellulose ether, calcium formate and starch ether, and stir for 3 minutes;

[0040] (2) Keep the rotating speed of the main shaft stirring b...

Embodiment 3

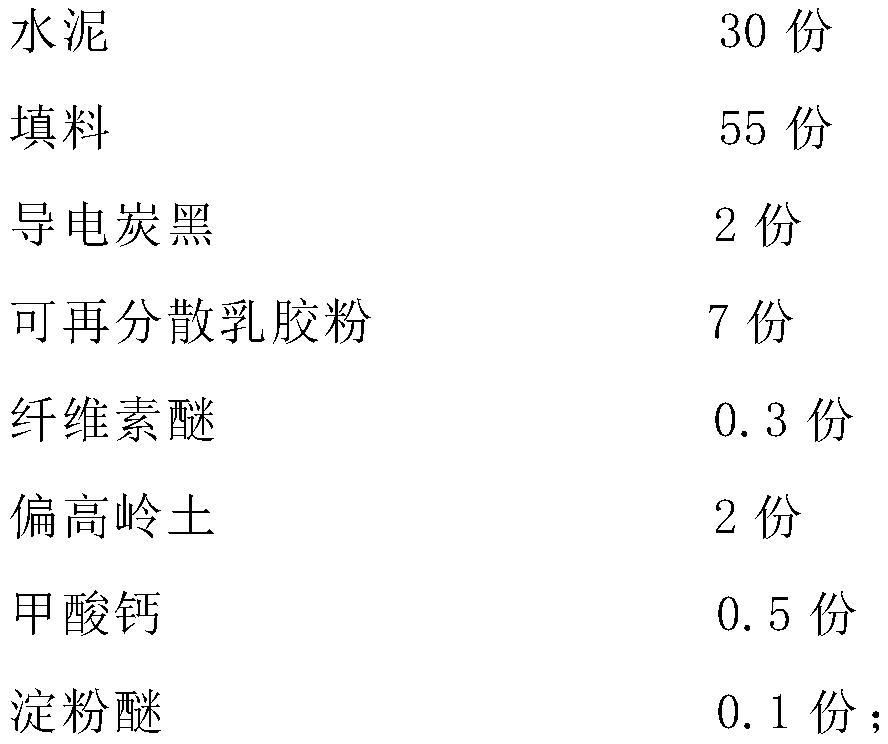

[0042] A kind of anti-radiation ceramic tile bonding mortar according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0043]

[0044] Wherein, the filler includes 30 parts of 40-70 mesh barium sulfate sand and 40 parts of other graded sands except barium sulfate sand.

[0045] The preparation method of the radiation-proof ceramic tile bonding mortar mainly includes the following steps carried out in sequence:

[0046] (1) Put the cement into the stirring tank, turn on the stirring blade and the flying knife, the rotating speed of the main shaft stirring blade is 300r / min, and the rotating speed of the flying knife is 2000r / min, and then slowly add the high-grade material into the stirring tank while stirring. Then disperse latex powder, cellulose ether, calcium formate and starch ether, and stir for 6 minutes;

[0047] (2) Keep the rotating speed of the main shaft stirring blade at 300r / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com