Ultra-wideband fluorescent quantum dot doped quartz amplification optical fiber and preparation method thereof

A fluorescent quantum dot and ultra-broadband technology, which is applied in the field of optical fiber doped with quantum dots and its preparation, can solve the problems of insufficient bandwidth and non-tunable emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing an ultra-broadband fluorescent quantum dot-doped quartz amplifying optical fiber, which is used to manufacture the above-mentioned ultra-broadband fluorescent quantum dot-doped quartz amplifying optical fiber, the steps are as follows:

[0038] 1) First, use the modified chemical vapor deposition method (MCVD) to deposit the cladding and silicon dioxide loose layer at high temperature to a translucent glass state;

[0039]2) Then, one or two or three kinds of quantum dots among PbS, PbSe, and PbTe are uniformly circulated and alternately deposited in the quartz substrate by atomic layer deposition (ALD);

[0040] 3) Repeat the process of 2) to control the doping concentration of different quantum dot materials and the size of the quantum dots through the deposition cycle;

[0041] 4) Place the deposited quartz substrate tube in a vacuum or nitrogen atmosphere for in-situ annealing. The annealing temperature is 100-500°C and the annealing time is 1...

Embodiment 1

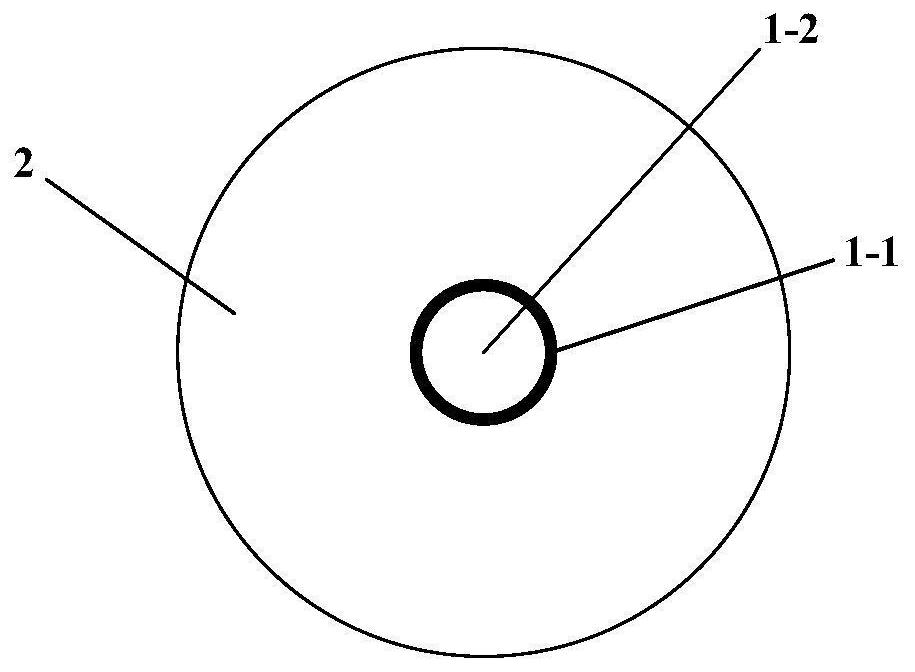

[0051] see figure 1 with figure 2 , an ultra-broadband fluorescent quantum dot-doped silica amplifying fiber, comprising a core 1 and a cladding 2, the core 1 comprising an outer silicon dioxide loose layer 1-1 and uniformly distributed semiconductor quantum dots of different sizes in the middle Dot material layer 1-2; the core 1 is located in the middle of the cladding 2. The silicon dioxide loose layer 1-1 is high-purity silicon dioxide or doped with a small concentration of high refractive index GeO 2 silica material. The semiconductor quantum dot material layer utilizes ALD technology and in-situ annealing technology to deposit PbS quantum dots of different sizes, and aluminum oxide Al 2 o 3 GeO with improved refractive index distribution 2 Material. By controlling the cycle period to be 50-500 cycles, the annealing temperature to be 200-300° C., and the annealing time to be 30 minutes, the size of the semiconductor PbS quantum dot is adjusted to be controlled betwe...

Embodiment 2

[0053] This embodiment is basically the same as the first embodiment, except that the process parameters are different, and the structural parameters of the optical fiber are adjusted.

[0054] see figure 1 with figure 2 , an ultra-broadband fluorescent quantum dot-doped silica amplifying fiber, comprising a core 1 and a cladding 2, the core 1 comprising an outer silicon dioxide loose layer 1-1 and uniformly distributed semiconductor quantum dots of different sizes in the middle Dot material layer 1-2; the core 1 is located in the middle of the cladding 2. The silicon dioxide loose layer 1-1 is high-purity silicon dioxide or doped with a small concentration of high refractive index GeO 2 silica material. The semiconductor quantum dot material layer utilizes ALD technology and in-situ annealing technology to deposit PbSe quantum dots of different sizes, and aluminum oxide Al 2 o 3 GeO with improved refractive index distribution 2 Material. By controlling the cycle perio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com