Electric power well lid die-casting die

A technology of die-casting molds and well covers, which is applied in the direction of manufacturing tools, grinding machines, grinding machine parts, etc., can solve the problems of contact impact between wood boards and well covers, displacement of upper mold and lower mold, and influence on production efficiency, so as to reduce labor intensity, The effect of improving product qualification rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

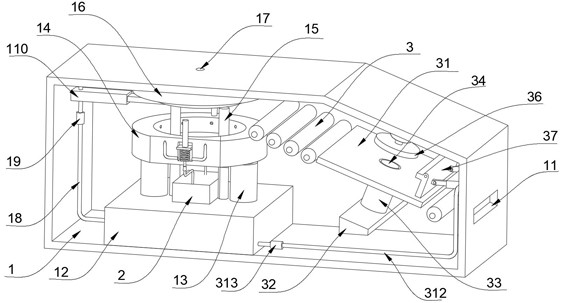

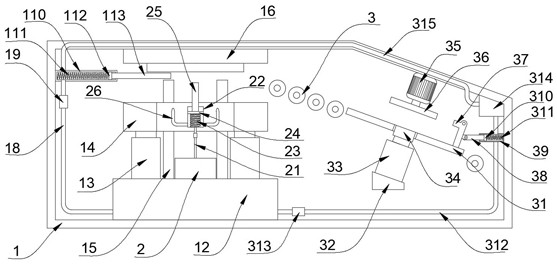

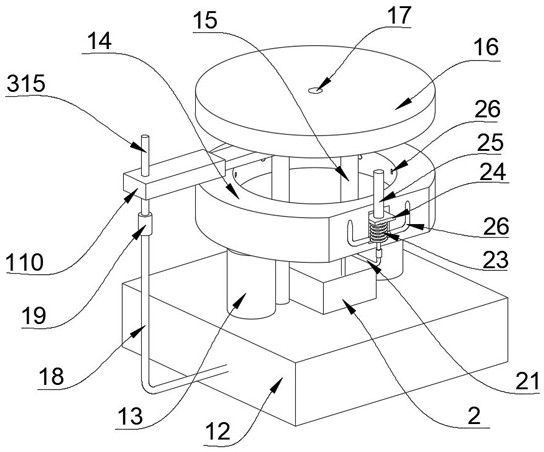

[0020] refer to Figure 1-3 , a power manhole cover die-casting mold, including a die-casting device, which is used to cast workpieces, and the die-casting device includes: a box body 1, a groove 11, a hydraulic oil tank 12, a hydraulic rod 13, a lower die 14, an ejector rod 15, and an upper die 16. Pouring pipeline 17, connecting pipe 18, first one-way valve 19, push block 110, return spring 111, slide plate 112, push rod 113, wherein a groove 11 is opened on one side of the box body 1, and the hydraulic oil tank 12 is fixedly connected Inside the box body 1, the hydraulic rod 13 is fixedly connected to the hydraulic oil tank 12, the lower die 14 is fixedly connected to the output end of the hydraulic rod 13, the ejector rod 15 is fixedly connected to the hydraulic oil tank 12, and the output end of the pouring pipe 17 is connected to the upper die 16....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com