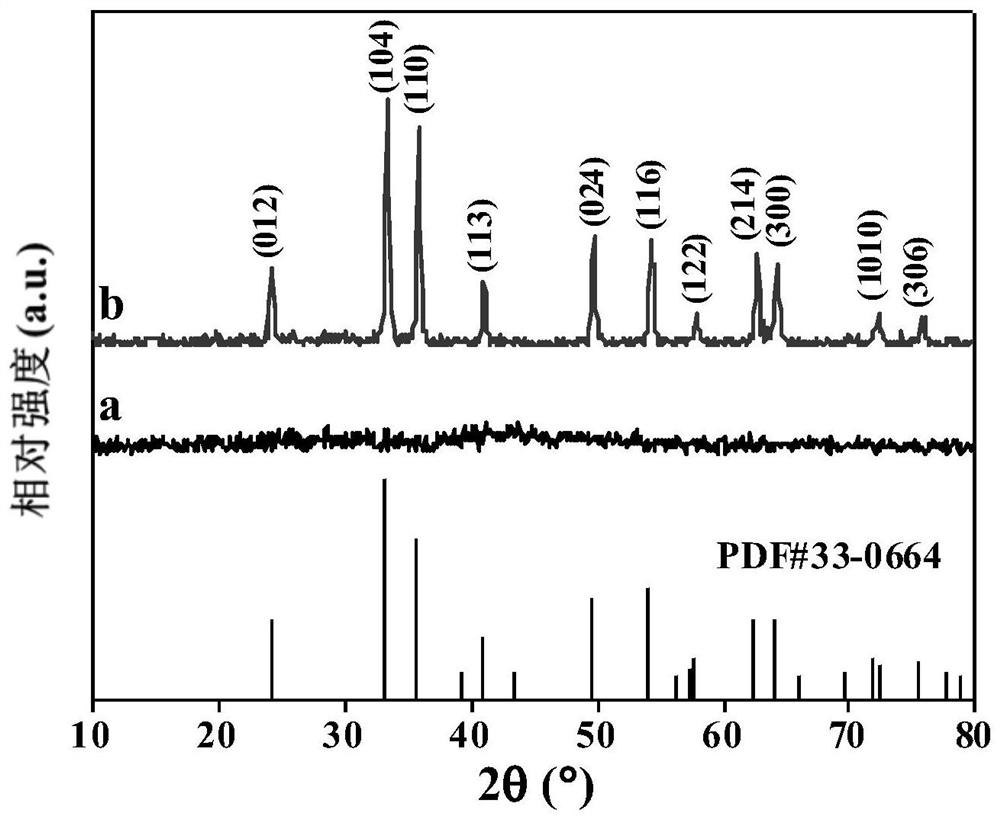

Nanometer iron oxide photocatalyst and preparation method thereof

An iron oxide photocatalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of reducing the photocatalytic activity of iron oxide, and achieve excellent Spectral absorption performance, uniform mesoporous structure, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

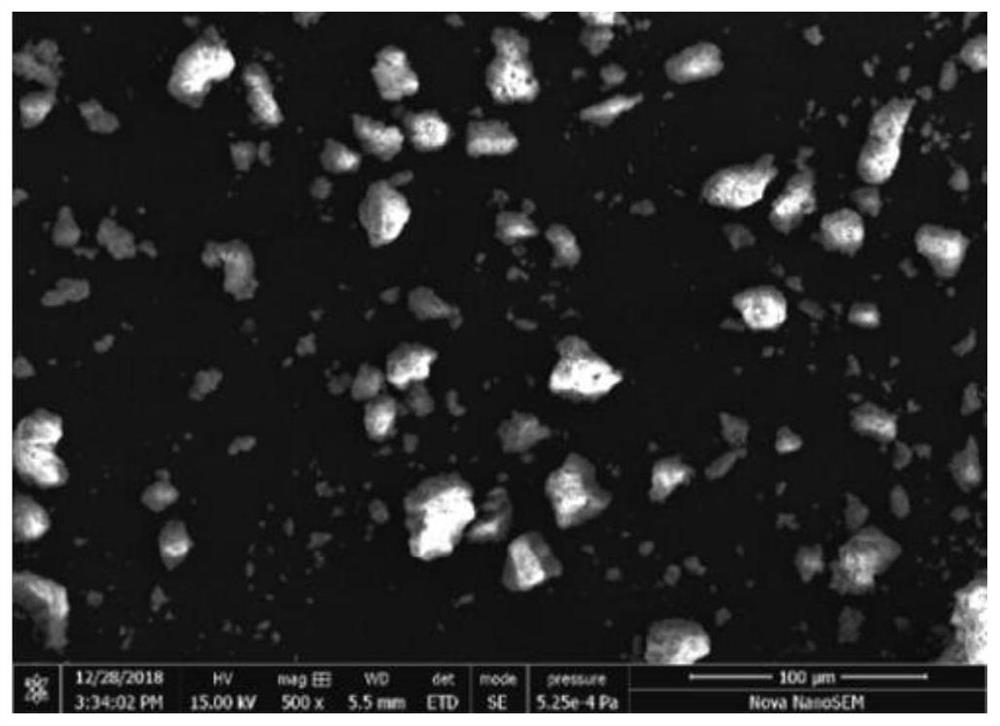

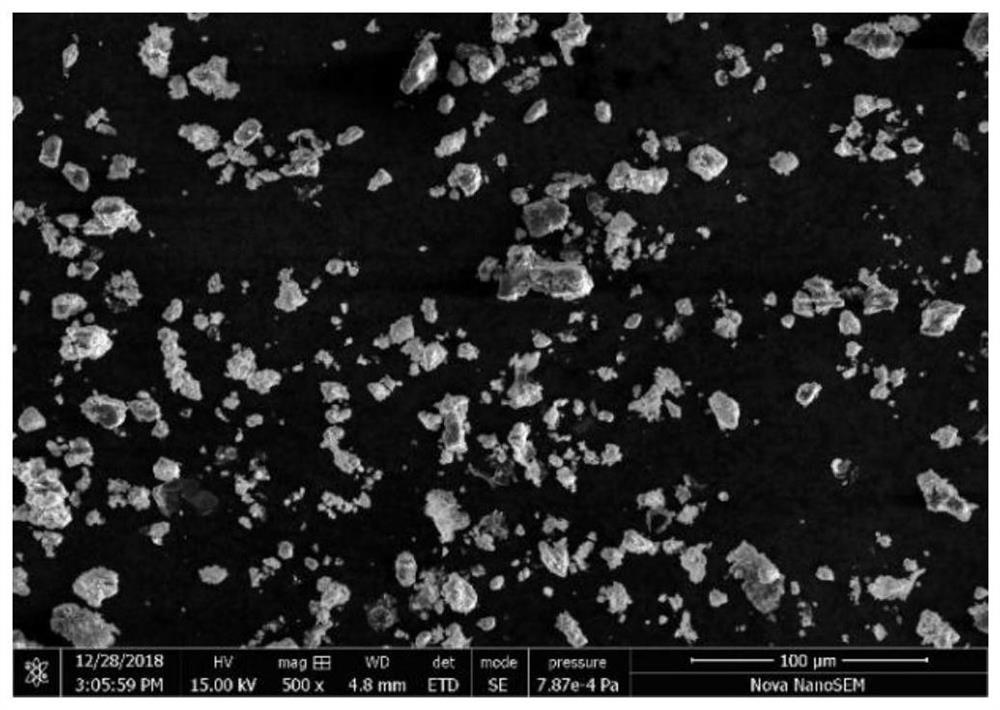

Embodiment 1

[0028] A preparation method of nano iron oxide photocatalyst, comprising the following steps:

[0029] The following parts are molar parts,

[0030] A. Put 23 parts of ferric chloride and 1 part of titanium dioxide into a 10wt% hydrochloric acid solution, heat to 60°C, and stir thoroughly to obtain a precursor; perform ultrasonic oscillation while stirring, and the power density of the ultrasonic wave is: 0.5~0.7W / cm 2 ;

[0031] B. Put the precursor into the reaction kettle and heat it to 210°C, and keep it warm for 3 hours;

[0032] C. Add the product in the reaction kettle to pure water at 85°C for stirring and crystallization for 30 hours;

[0033] D, the product of step C is suction filtered and washed;

[0034] E. Put the product of step D into a muffle furnace, and heat to 935° C. for calcination for 8 hours;

[0035] F. Reduce the temperature of the muffle furnace at a rate of 150°C / hour. When the temperature of the muffle furnace drops to 350°C, the muffle furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com