High-internal-phase switching emulsion with stable particles, preparation method and particle recovery method

A technology with high internal phase and particles, applied in the field of emulsion preparation, can solve problems such as instability, and achieve the effect of reducing the possibility of coalescence, good recyclability, and reducing environmental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The quality of each main substance in this implementation is as follows: FA: 0.0060g, OA: 0.0044g, SiO 2 : 0.0150g, octane 3.75g.

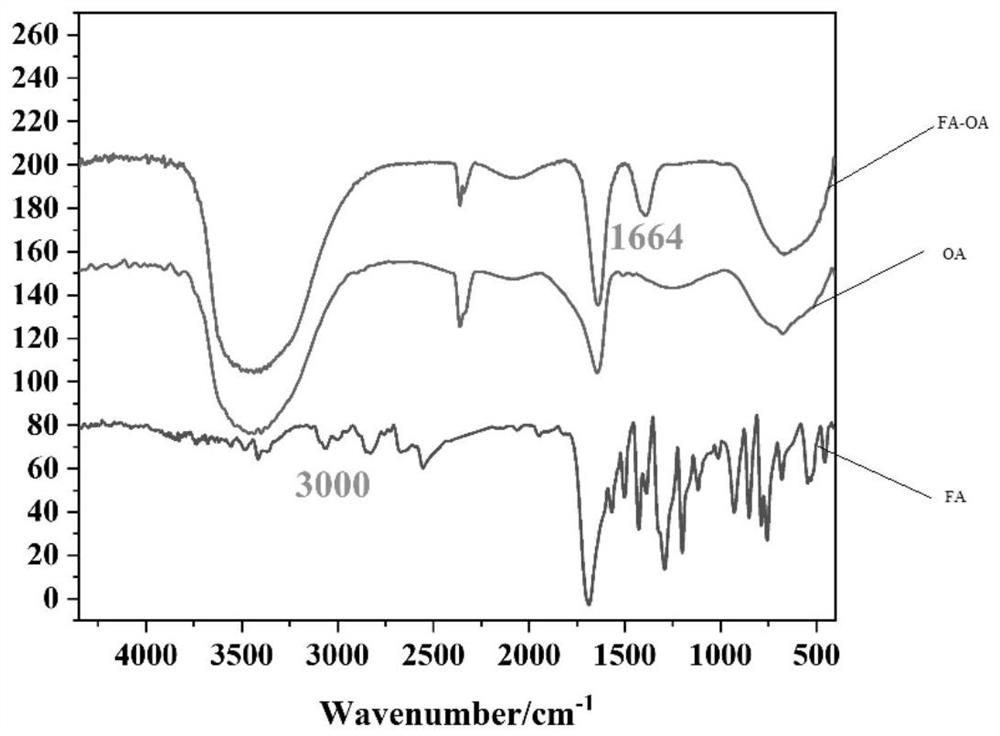

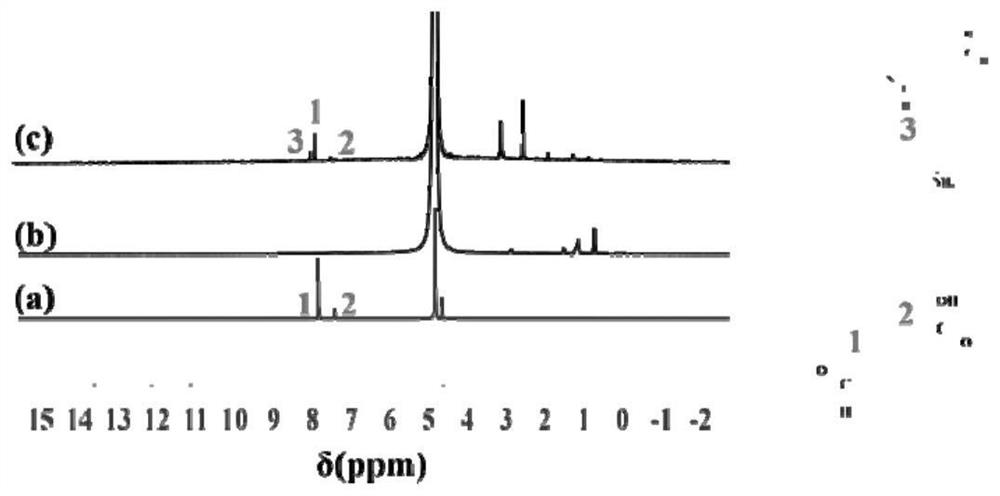

[0031] S1: Add FA and OA into NaOH aqueous solution, stir continuously until they are completely dissolved, and obtain a colorless and transparent dynamic covalent bond surfactant aqueous solution, which is characterized by infrared and NMR. The results are as follows figure 1 and figure 2 , figure 2 (a) is FA-OA aqueous solution, (b) is FA, (c) is OA;

[0032] S2: SiO with particle size within 20-400nm 2 Nanoparticles are added to an aqueous solution of a dynamic covalent bond surfactant to obtain an aqueous phase;

[0033] S3: Add octane to the water phase, and use a 20000r / min homogenizer to stir for 2 minutes to obtain a particle-stabilized high internal phase switch emulsion.

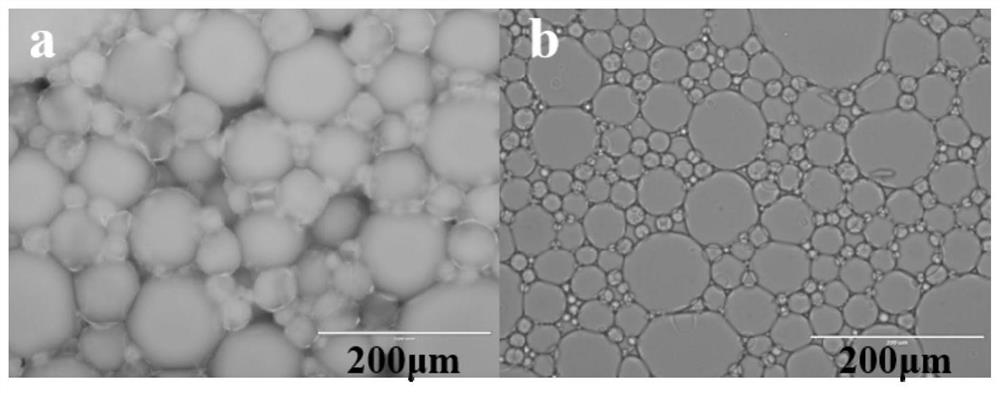

[0034] Fluorescence, optical micrographs, and optical photographs of the particle-stabilized high-internal phase switch emulsion prepared in this example...

Embodiment 2

[0036] The quality of each main substance in this implementation is as follows: FA: 0.0110g, OA: 0.0087g, SiO 2 : 0.0200g, octane 4.00g.

[0037] S1: Add FA and OA into NaOH aqueous solution, stir continuously until completely dissolved, and obtain a colorless and transparent dynamic covalent bond surfactant aqueous solution, which is characterized by infrared and nuclear magnetic resonance;

[0038] S2: SiO with particle size within 20-400nm 2 Nanoparticles are added to an aqueous solution of a dynamic covalent bond surfactant to obtain an aqueous phase;

[0039] S3: Add octane to the water phase, and stir for 4 minutes with a 18000 r / min homogenizer to obtain a particle-stabilized high internal phase switch emulsion.

Embodiment 3

[0041] The quality of each main substance in this implementation is as follows: FA: 0.017g, OA: 0.0130g, SiO 2 : 0.0250g, octane 4.10g.

[0042] S1: Add FA and OA into NaOH aqueous solution, stir continuously until completely dissolved, and obtain a colorless and transparent dynamic covalent bond surfactant aqueous solution, which is characterized by infrared and nuclear magnetic resonance;

[0043] S2: SiO with particle size within 20-400nm 2 Nanoparticles are added to an aqueous solution of a dynamic covalent bond surfactant to obtain an aqueous phase;

[0044] S3: Add octane to the water phase, and use a 22000r / min homogenizer to stir for 3 minutes to obtain a particle-stabilized high internal phase switch emulsion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com