Shell, preparation method thereof and electronic equipment

A shell, ceramic powder technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, chassis/box/cabinet/drawer parts, etc. Improvement, difficulty in obtaining ceramic texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] see Figure 4 , a flow chart of a method for preparing a casing provided in an embodiment of the application, the preparation method for preparing the casing 100 of any of the above-mentioned embodiments includes:

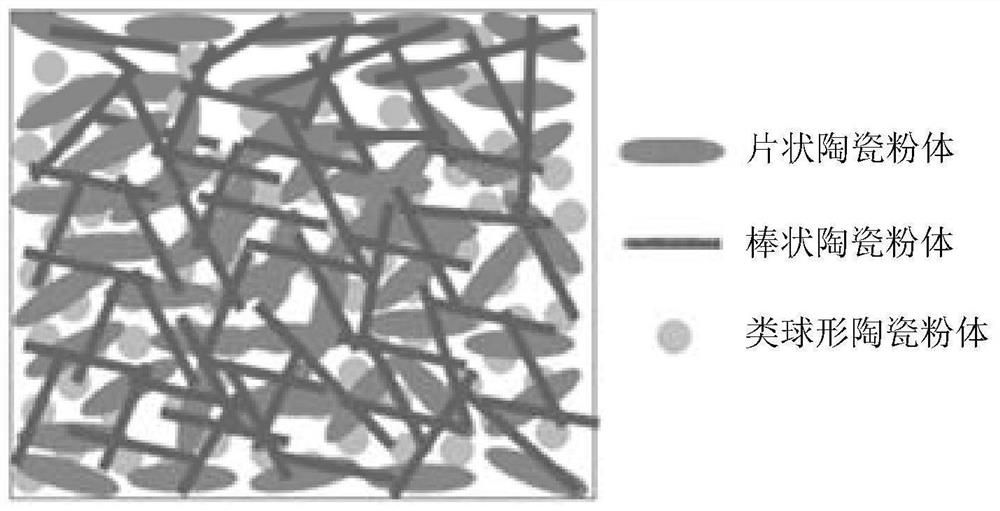

[0050] S101: After the mixed material is modified, it is mixed with an initiator and granulated to obtain a mixed powder, and the mixed material includes at least one of rod-shaped ceramic powder and fiber material, and flake-shaped ceramic powder.

[0051] S102: The mixed powder is blended with the polymer, and the mixer is granulated to form a feed for injection molding.

[0052] S103: The injection molding feedstock is injected to form a polymer-ceramic composite sheet.

[0053] S104: After pressing the polymer-ceramic composite sheet, heat treatment to obtain a polymer-ceramic composite layer to obtain a shell.

[0054] The preparation method of the casing 100 provided by the present application is simple to operate, easy to produce on a large scale, a...

Embodiment 1

[0065] A shell, comprising flake silicon powder, rod-shaped zirconia, spherical alumina and polyphenylene sulfide, wherein the mass ratio of flake silicon powder in the shell is 5%, and the mass ratio of rod-shaped zirconia is 5%, and the mass proportion of spherical alumina is 70%.

Embodiment 2

[0067] A shell, comprising flaky zirconia, rod-shaped silicon carbide, spherical-like alumina and polyphenylene sulfide, wherein the mass ratio of flaky zirconia in the shell is 5%, and the mass ratio of rod-shaped silicon carbide is 5%, and the mass proportion of spherical alumina is 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com