Double-layer suspension infrared thermopile and preparation method thereof

A thermopile and infrared technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric devices using only the Peltier or Seebeck effect, electric radiation detectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

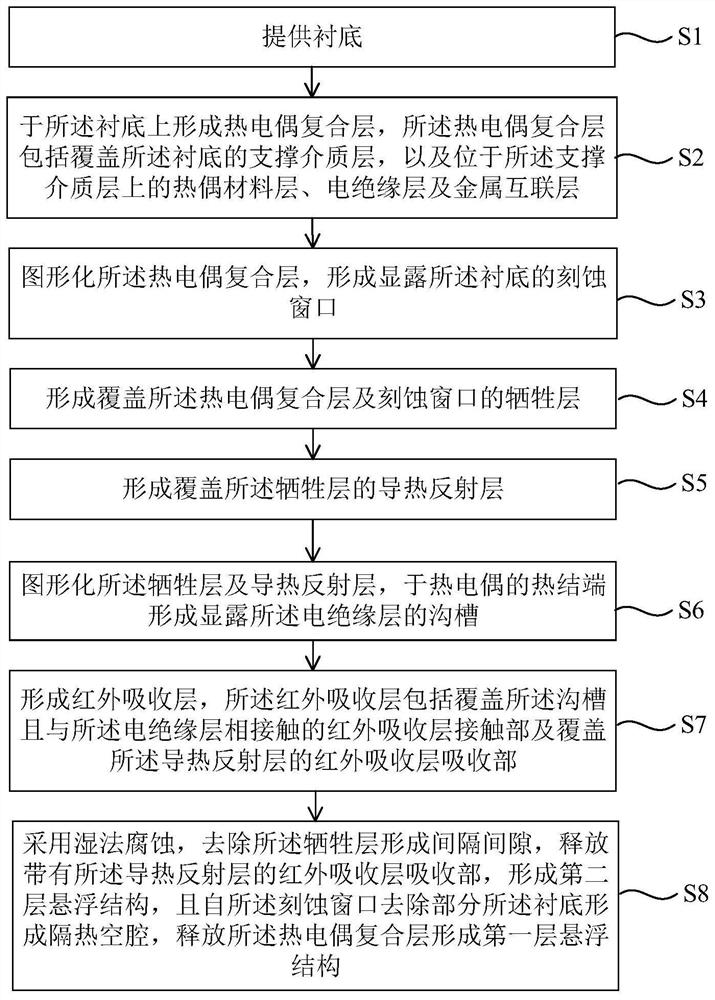

[0069] Such as figure 1 As shown, this embodiment provides a method for preparing a double-layer suspended infrared thermopile, comprising the following steps:

[0070] S1: provide the substrate;

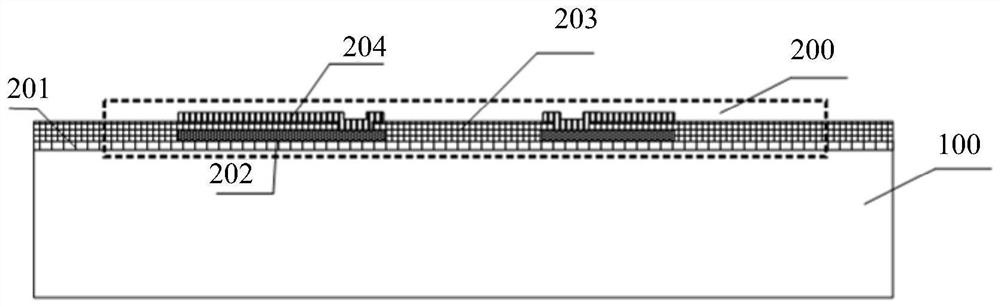

[0071] S2: Forming a thermocouple composite layer on the substrate, the thermocouple composite layer includes a support medium layer covering the substrate, and a thermocouple material layer, an electrical insulation layer, and a metal layer located on the support medium layer interconnection layer;

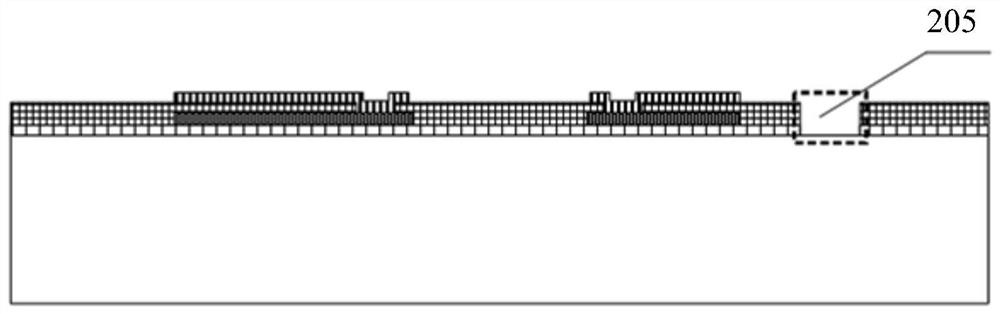

[0072] S3: patterning the thermocouple composite layer to form an etching window exposing the substrate;

[0073] S4: forming a sacrificial layer covering the thermocouple composite layer and the etching window;

[0074] S5: forming a thermally conductive reflective layer covering the sacrificial layer;

[0075] S6: patterning the sacrificial layer and the heat-conducting reflective layer, forming a groove exposing the electrical insulation layer at the thermal junction end of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com