Anti-imprint pressure resistance detection mechanism for automatic production of lithium battery

A detection mechanism and lithium battery technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, strength characteristics, etc., can solve problems such as inconvenient collection of items and no protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

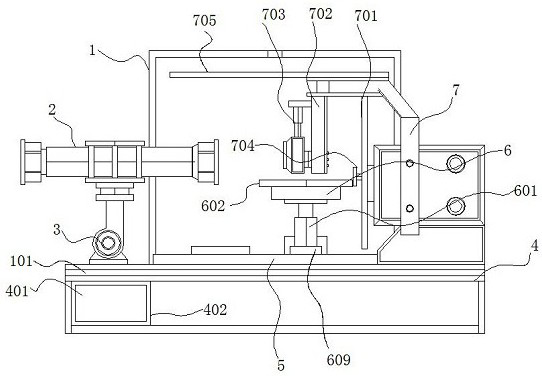

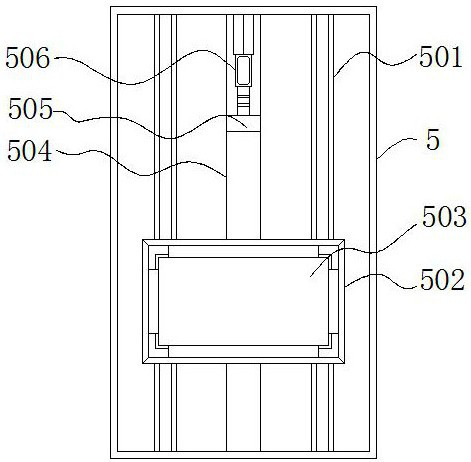

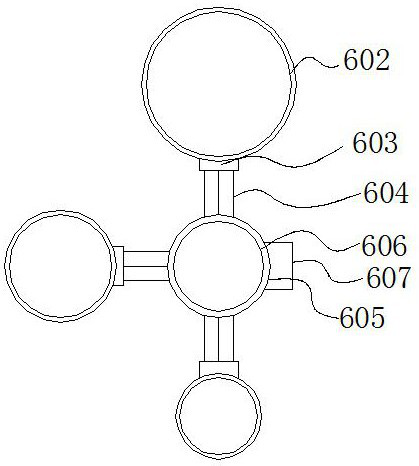

[0030] see figure 1 and Figure 6, the present invention provides a technical solution: a pressure resistance detection mechanism for automatic production of lithium batteries to prevent imprinting, comprising: a protection device 1; a detection eyepiece 2, the detection eyepiece 2 is arranged on the left end of the protection device 1; Device 1 comprises: limiting groove 101, and limiting groove 101 is installed on the two ends outside the top of collecting mechanism 4; Auxiliary frame 103, and auxiliary frame 103 is arranged on the inside of limiting groove 101; Middle frame 102, and middle frame 102 is installed on auxiliary Inside the frame 103, the inside of the auxiliary frame 103 is a hollow structure, and the inside of the auxiliary frame 103 is movably connected to the middle frame 102, which can prevent the lithium battery from bursting when the lithium battery is tested against pressure. For potential safety hazards, the design of the superimposed structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com