Novel green environment-friendly chemi-mechanical pulp soaking additive and method for applying same to straw pulping

A green, environmentally friendly, chemical-mechanical pulping technology, applied in pulp beating/refining method, non-fiber pulp addition, washing/replacement of pulp treatment liquid, etc., can solve problems such as low refining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

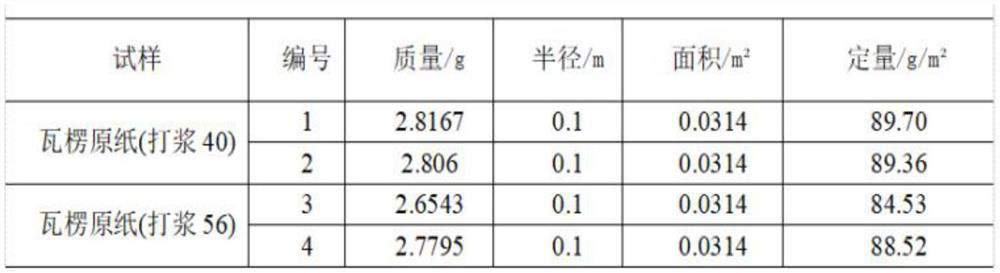

Image

Examples

Embodiment 1

[0027] A novel mechanical pulp soaked green additives, in parts by weight, comprising 17 parts of urea, 26.5 parts of sodium carbonate, sodium percarbonate 34 parts, 11 parts of sodium chloride, 7 parts of silicate, 1 part of sodium phosphate 0.1 parts of aluminum.

[0028] A novel mechanical pulp soaked green straw pulping additive method, comprising the steps of, preparing a flowchart see figure 1 , Where denotes additive dosing levels above formulation.

[0029] Step a: straw feed enters the pulverizer via pneumatic conveying equipment, then remove dust, screened again transferred after immersion tank;

[0030] Step 2: 24m 3 3t raw water and placed in the immersion tank, added 25kg as claimed in any of claims 1-3 according to a new green mechanical pulp soaking additives, adjusted to pH 12-13 for the preparation of pretreatment of mechanical pulp;

[0031] Step Three: Soak the pool soak 40-60 minutes into the disc refiner, refiner began beating;

[0032] Step Four: refining the...

Embodiment 2

[0036] A novel mechanical pulp soaked green additives, in parts by weight, comprising 18 parts of urea, 27.5 parts of sodium carbonate, 35 parts of sodium percarbonate, 12 parts of sodium chloride, 8 parts of silicate, 2 parts of sodium phosphate 0.5 parts of aluminum.

[0037] A novel mechanical pulp soaked green straw pulping additive method, comprising the steps of, preparing a flowchart see figure 1 , Where denotes additive dosing levels above formulation.

[0038] Step a: straw feed enters the pulverizer via pneumatic conveying equipment, then remove dust, screened again transferred after immersion tank;

[0039] Step 2: 24m 3 3t raw water and placed in the immersion tank, added 25kg as claimed in any of claims 1-3 according to a new green mechanical pulp soaking additives, adjusted to pH 12-13 for the preparation of pretreatment of mechanical pulp;

[0040] Step Three: Soak the pool soak 40-60 minutes into the disc refiner, refiner began beating;

[0041] Step Four: refining...

Embodiment 3

[0045] A novel mechanical pulp soaked green additive, characterized in that, in parts by weight, comprising 17 parts of urea, 27 parts of sodium carbonate, sodium percarbonate 34 parts, 11 parts of sodium chloride, 7 parts of silicate, sodium 1 part, 0.2 parts aluminum phosphate.

[0046] A novel mechanical pulp soaked green straw pulping additive method, comprising the steps of, preparing a flowchart see figure 1 , Where denotes additive dosing levels above formulation.

[0047] Step a: straw feed enters the pulverizer via pneumatic conveying equipment, then remove dust, screened again transferred after immersion tank;

[0048] Step 2: 24m 3 3t raw water and placed in the immersion tank, added 25kg as claimed in any of claims 1-3 according to a new green mechanical pulp soaking additives, adjusted to pH 12-13 for the preparation of pretreatment of mechanical pulp;

[0049] Step Three: Soak the pool soak 40-60 minutes into the disc refiner, refiner began beating;

[0050] Step Fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com