Yeast rouxii CJ1 and application thereof

A technology for yeast and yeast, applied in yeast CJ1 and its application field, can solve the problem that the SOD activity of Zygosaccharomyces ruckeri has not been reported, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Screening of Salt Tolerance and High SOD Enzyme Activity Rushii Saccharomyces CJ1 Strain

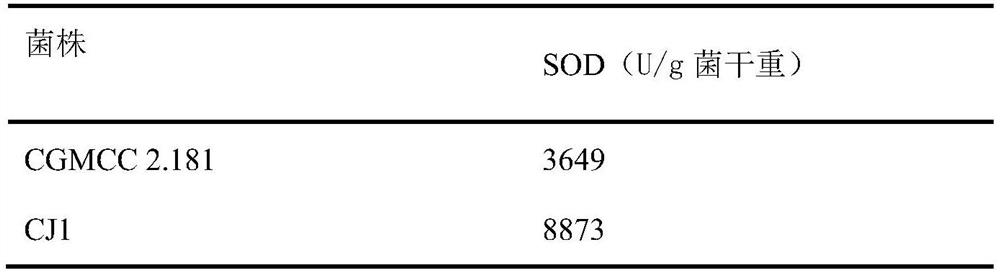

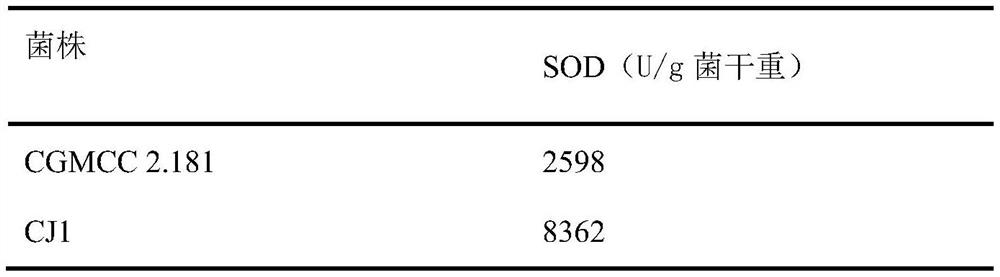

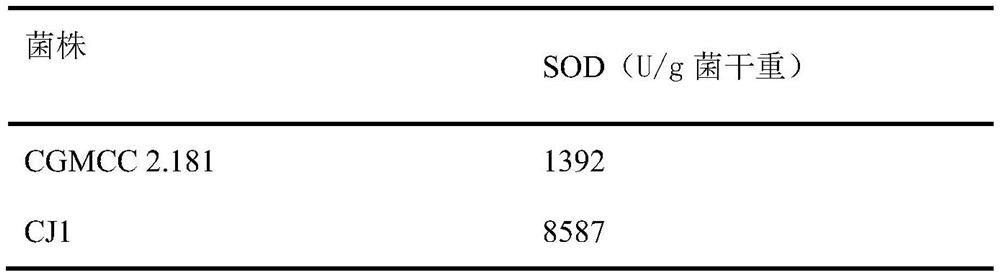

[0038] Using Zygosaccharomyces rouxii (Zygosaccharomyces rouxii) CGMCC 2.181 as the starting strain, select ARTP mutagenesis (irradiation for 90s) with a lethal rate of 90% to mutate Zygosaccharomyces rouxii, dilute the mutagenized bacterial solution and spread it evenly On a high-concentration sodium chloride plate (sodium chloride concentration 100g / L), culture in the dark at 30°C for 2-3 days, and then pick mutants with larger colonies and inoculate them into the fermentation medium. The SOD enzyme activity of the mutant strain inoculated into the fermentation medium was measured, and compared with the original strain, a strain of Zygomyces rouckeri with high SOD enzyme activity in a high-salt stress environment was obtained. The SOD enzyme activity of the strain was greatly improved compared with the original strain. The results are shown in Table 1, Table 2 and Table 3. The ...

Embodiment 2

[0047] This example mainly investigates the effect of inoculation of soy sauce with Saccharomyces rouxii CJ1 on the activity of soy sauce SOD enzyme. The detection method of SOD enzyme activity adopts GB / T5009.171.

[0048] Soybean and wheat were heated and denatured, mixed according to the ratio of 7:3, and the water content was adjusted to 45%, and then inoculated with Aspergillus oryzae, cultivated at 33°C for 3 days to obtain soy sauce koji.

[0049] Prepare soy sauce koji and 23% salt water according to the mass ratio of 1:1.8, mix well and put into fermenter for fermentation, the fermentation temperature is 33°C.

[0050] Using the mutant strains CJ1 and CGMCC 2.181 as the experimental strains, inoculate the CJ1 and CGMCC 2.181 strains from the slant to the seed medium for expansion; the components of the seed medium are: 10% of soy sauce crude oil, 4% of glucose, and 12% of edible salt , and make up the rest with water, and sterilize by high-pressure steam at 121°C for...

Embodiment 3

[0055]This example investigates the effect of different inoculation time of CJ1 on soy sauce SOD enzyme activity

[0056] The preparation process of this example refers to Example 2, and the specific difference is that the inoculation time of CJ1 is respectively inoculated into the moromi fermented for 10, 15, 20, 25, and 30 days. After the fermentation, the SOD enzyme activity in the crude oil was measured and compared, as shown in Table 5. It can be seen from Table 3 that the crude oil SOD enzyme activity was the highest in the moromi fermented by the CJ1 strain inoculated for 15 days.

[0057] Table 5. Effect of CJ1 inoculation time on crude oil SOD enzyme activity

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com