Method for preparing phenolic substances through photo-thermal pyrolysis of waste fan blades

A technology for fan blades and phenolic substances is applied in the field of photothermal pyrolysis of waste fan blades to prepare phenolic substances, and can solve the problem of not providing effective treatment and resource utilization methods for waste fan blades, fan blades occupying large land resources, and environmental damage. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

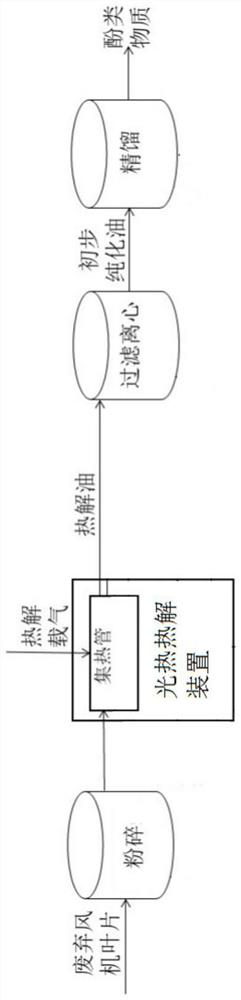

[0026] Such as figure 1 As shown, a method for preparing phenolic substances by photothermal pyrolysis of waste fan blades in this embodiment comprises the following steps:

[0027] S1. Putting scrapped wind turbine rotor blades into a crushing device, and obtaining broken fan blades through mechanical crushing;

[0028] S2. The blades of the broken fan are pyrolyzed in the heat collecting tube of the trough solar collector. The pyrolysis conditions are: nitrogen gas is introduced, the air flow is 60ml / min, the heating rate is 5K / min, the temperature is 300°C, and the heat preservation The time is 80min. During the pyrolysis process, the yields of tar and pyrolysis coke are 4.23% and 30.42% respectively;

[0029] S3. The tar obtained in S2 is first filtered to remove solid impurities, and then centrifuged at a speed of 6000r / min to remove light components in the tar, and the tar obtained after centrifugation is subjected to rectification treatment to obtain phenol with a mass...

Embodiment 2

[0033] A method for preparing phenolic substances by photothermal pyrolysis of waste fan blades in this embodiment comprises the following steps:

[0034] S1. Putting scrapped wind turbine rotor blades into a crushing device, and obtaining broken fan blades through mechanical crushing;

[0035] S2. The blades of the broken fan are pyrolyzed in the heat collecting tube of the trough solar collector. The pyrolysis conditions are: carbon dioxide is introduced, the air flow is 160ml / min, the heating rate is 15K / min, the temperature is 450°C, and the holding time is 100min, during the pyrolysis process, the yields of tar and pyrolysis coke were 7.26% and 40.53% respectively;

[0036] S3. The tar obtained in S2 is first filtered to remove solid impurities, and then centrifuged at a speed of 7000r / min to remove light components in the tar, and the tar obtained after centrifugation is subjected to rectification treatment to obtain phenol with a mass ratio of 16.85%. , 10.43% of 4-iso...

Embodiment 3

[0039] A method for preparing phenolic substances by photothermal pyrolysis of waste fan blades in this embodiment comprises the following steps:

[0040] S1. Putting scrapped wind turbine rotor blades into a crushing device, and obtaining broken fan blades through mechanical crushing;

[0041] S2. The blades of the broken fan are pyrolyzed in the heat collecting tube of the trough solar collector. The pyrolysis conditions are: carbon dioxide is introduced, the air flow is 250ml / min, the heating rate is 30K / min, the temperature is 550°C, and the holding time is During the pyrolysis process, the yields of tar and pyrolysis coke were 15.35% and 50.69% respectively;

[0042] S3, the tar obtained in S2 is first filtered to remove solid impurities, and then centrifuged at a speed of 8000r / min to remove light components in the tar, and the tar obtained after centrifugation is subjected to rectification treatment to obtain 19.32% by mass ratio Phenol, 11.91% 4-isopropenylphenol and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com