Manganese sulfate production system based on manganese oxide ore

A production system and technology of manganese oxide ore, applied in the direction of manganese sulfate, etc., can solve the problems of low production efficiency, large monitoring error of safety intelligent monitoring technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

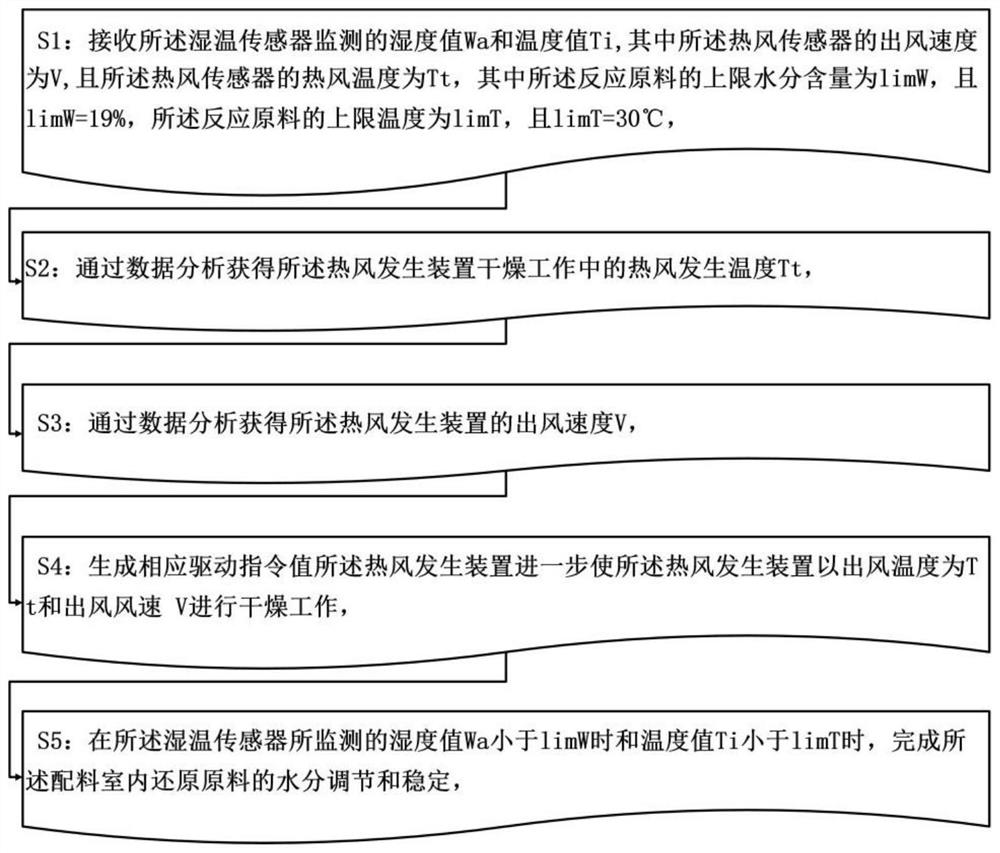

[0037]This embodiment constructs a kind of production system that carries out automatic feeding to the production of described manganese sulfate and accurately screens and stirs the reaction raw materials;

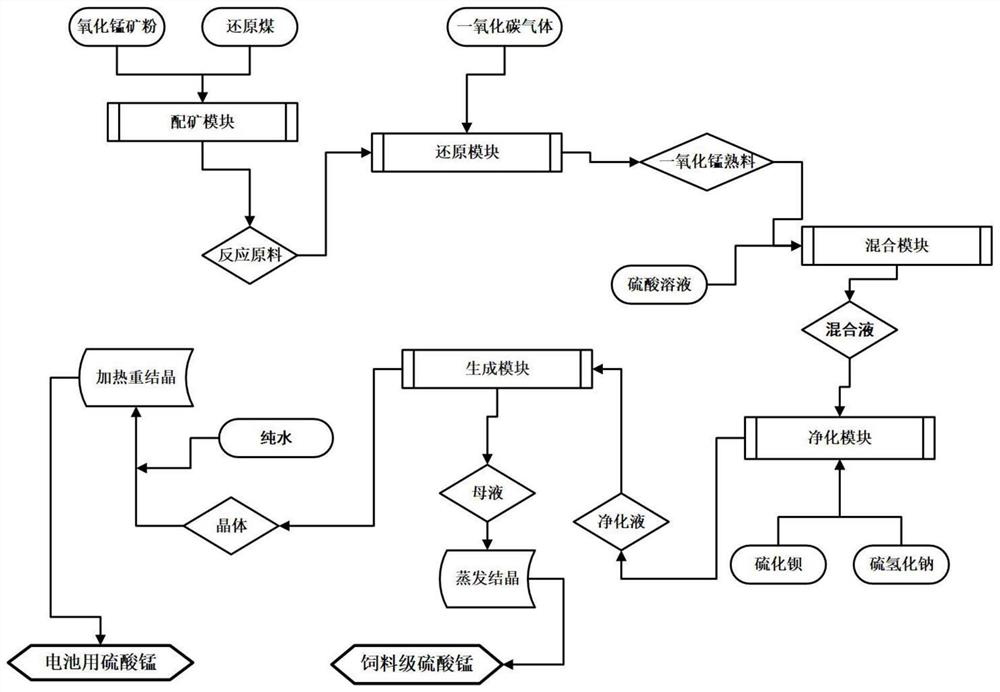

[0038] A manganese sulfate production system based on manganese oxide ore, the manganese sulfate production system includes an ore blending module that automatically feeds manganese oxide ore powder and reduced coal separately and performs effective and uniform mixing to obtain reaction raw materials; Feed carbon monoxide gas under monitoring for reduction and slaking until the divalent manganese in the reaction raw materials is reduced to monovalent manganese to obtain a reduction module of manganese monoxide clinker, adding sulfuric acid solution to the manganese monoxide clinker for mixed reaction and further A mixing module for obtaining a mixed solution, adding barium sulfide and sodium hydrosulfide to the mixed solution for cyclic and repeated stirring and filtering t...

Embodiment 2

[0053] This embodiment constructs a protection system for temperature monitoring of the high-temperature reduction step in the production system;

[0054]A manganese sulfate production system based on manganese oxide ore, the manganese sulfate production system includes an ore blending module that automatically feeds manganese oxide ore powder and reduced coal separately and performs effective and uniform mixing to obtain reaction raw materials; Feed carbon monoxide gas under monitoring for reduction and slaking until the divalent manganese in the reaction raw materials is reduced to monovalent manganese to obtain a reduction module of manganese monoxide clinker, adding sulfuric acid solution to the manganese monoxide clinker for mixed reaction and further A mixing module for obtaining a mixed solution, adding barium sulfide and sodium hydrosulfide to the mixed solution for cyclic and repeated stirring and filtering to obtain a purification module for the corresponding purified...

Embodiment 3

[0082] This embodiment constructs a generation system for automatically monitoring and judging the leaching situation of the leachate in the production process and further controlling the working conditions of the leaching module;

[0083] A manganese sulfate production system based on manganese oxide ore, the manganese sulfate production system includes an ore blending module that automatically feeds manganese oxide ore powder and reduced coal separately and performs effective and uniform mixing to obtain reaction raw materials; Feed carbon monoxide gas under monitoring for reduction and slaking until the divalent manganese in the reaction raw materials is reduced to monovalent manganese to obtain a reduction module of manganese monoxide clinker, adding sulfuric acid solution to the manganese monoxide clinker for mixed reaction and further A mixing module for obtaining a mixed solution, adding barium sulfide and sodium hydrosulfide to the mixed solution for cyclic and repeated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com