Lens design method

A design method and lens technology, applied in optical components, optics, instruments, etc., can solve problems such as difficult imaging of lenses, large deformation of plastic lenses, and abnormal imaging of lens systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

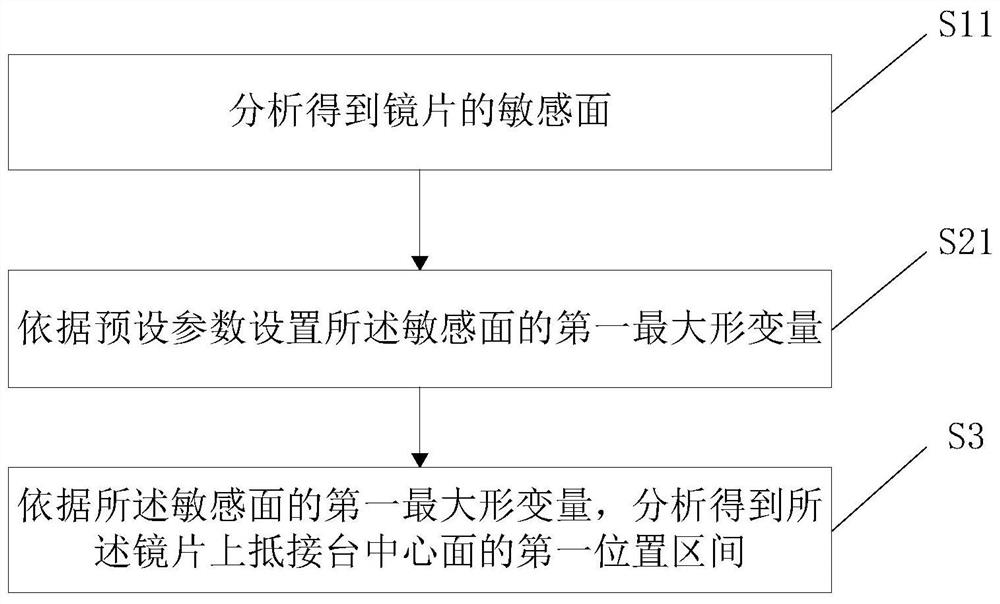

[0094] Such as figure 1 , Figure 7 with Figure 8 Shown, a kind of lens design method comprises the following steps:

[0095] S11. Analyzing and obtaining the sensitive surface of the lens.

[0096] First calculate the curved surfaces on both sides of the lens, which of the two curved surfaces is more sensitive, and use the more sensitive curved surface as the sensitive surface.

[0097] S21. Set the first maximum deformation amount of the sensitive surface according to preset parameters.

[0098] According to the installation of the first lens L1 to the sixth lens L6 in the lens barrel 1, the focal length, focal power, image height, aberration and other related parameters of the lens are used as preset parameters to limit the deformation of the lens, and then The first maximum deformation of the sensitive surface is formed. Therefore, the lens can only meet the relevant parameter requirements when the deformation of the sensitive surface is less than or equal to the fir...

Embodiment 2

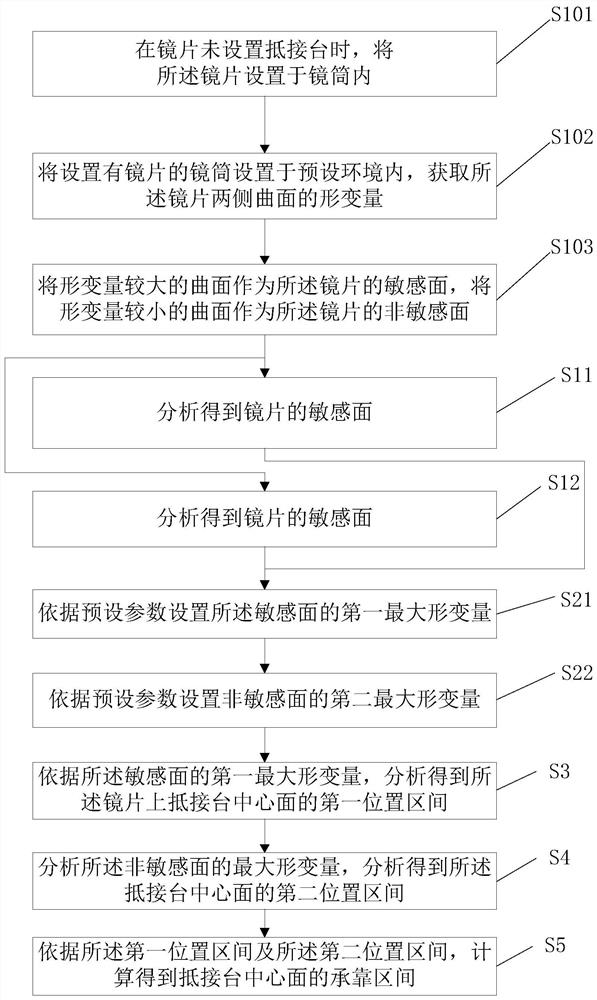

[0103] Such as figure 1 , figure 2 with Figure 8 Shown, a kind of lens design method comprises the following steps:

[0104] S101 . When the lens is not provided with an abutment platform, place the lens in the lens barrel 1 .

[0105] In the current state, if the lens is directly placed in the lens barrel 1, the lens will be deformed after abnormal temperature.

[0106] S102. Set the lens barrel 1 provided with the lenses in a preset environment, and obtain the deformation of the curved surfaces on both sides of the lenses.

[0107] The preset environment can be changed according to the user's settings. Specifically, the preset environment mainly refers to different temperature environments. After a period of time, the lens will be deformed, and the user can measure the deformation on both sides of the lens.

[0108] S103. Use a curved surface with a larger deformation amount as a sensitive surface of the lens, and use a curved surface with a smaller deformation amount...

Embodiment 3

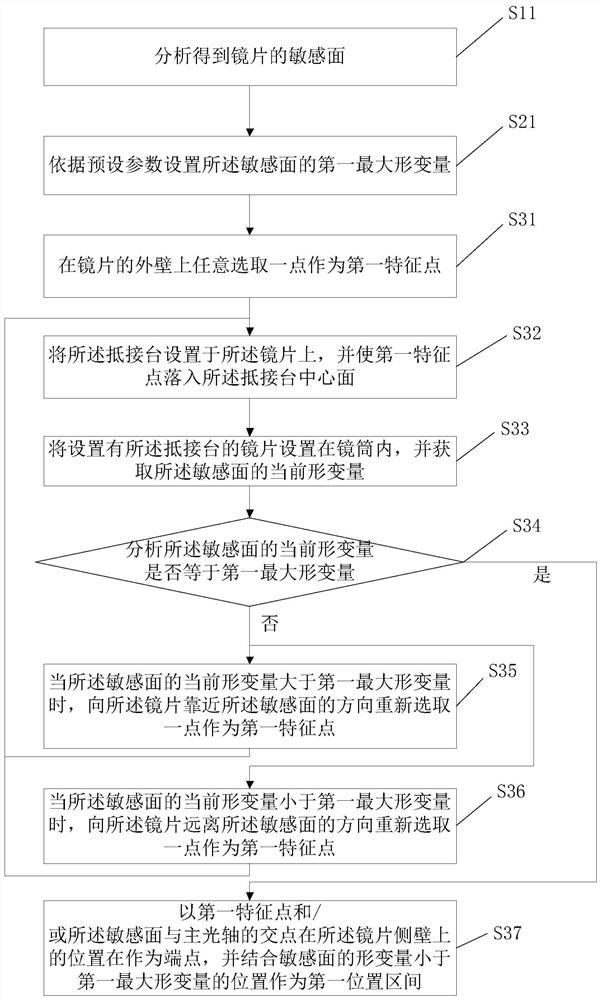

[0120] Such as image 3 , Figure 7 with Figure 8 Shown, a kind of lens design method comprises the following steps:

[0121] S11. Analyzing and obtaining the sensitive surface of the lens.

[0122] S21. Set the first maximum deformation amount of the sensitive surface according to preset parameters.

[0123] S31. Randomly select a point on the outer wall of the lens as the first feature point.

[0124] S32. Set the abutment platform on the lens, and make the first feature point fall into the central plane of the abutment platform;

[0125] S33. Set the lens provided with the abutting platform in the lens barrel 1, and acquire the current deformation of the sensitive surface.

[0126] After the abutment platform is set on the first feature point, the abutment platform is located at the end close to the sensitive surface, and in the current state, the lens is placed in the lens barrel 1 again, and the current deformation of the sensitive surface is obtained. At this time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com