Method for determining starting scheme of catalytic bed of hydrogen peroxide rocket engine

A rocket engine, hydrogen peroxide technology, applied in radiation pyrometry, chemical analysis by catalysis, weighing by removing certain components, etc., can solve problems such as failure to design a start-up plan in a targeted manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

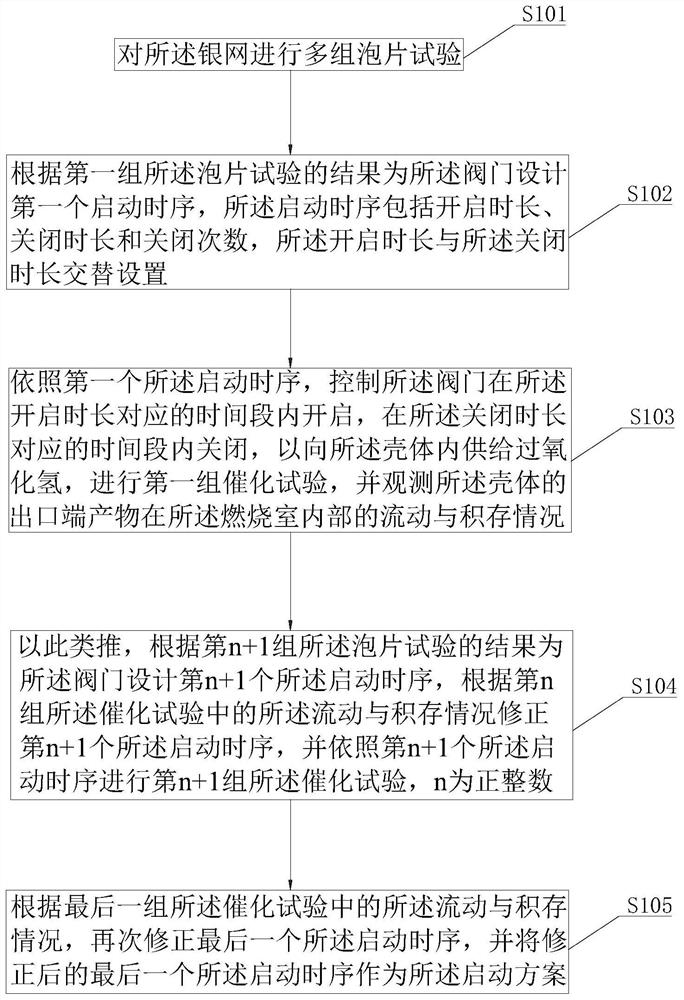

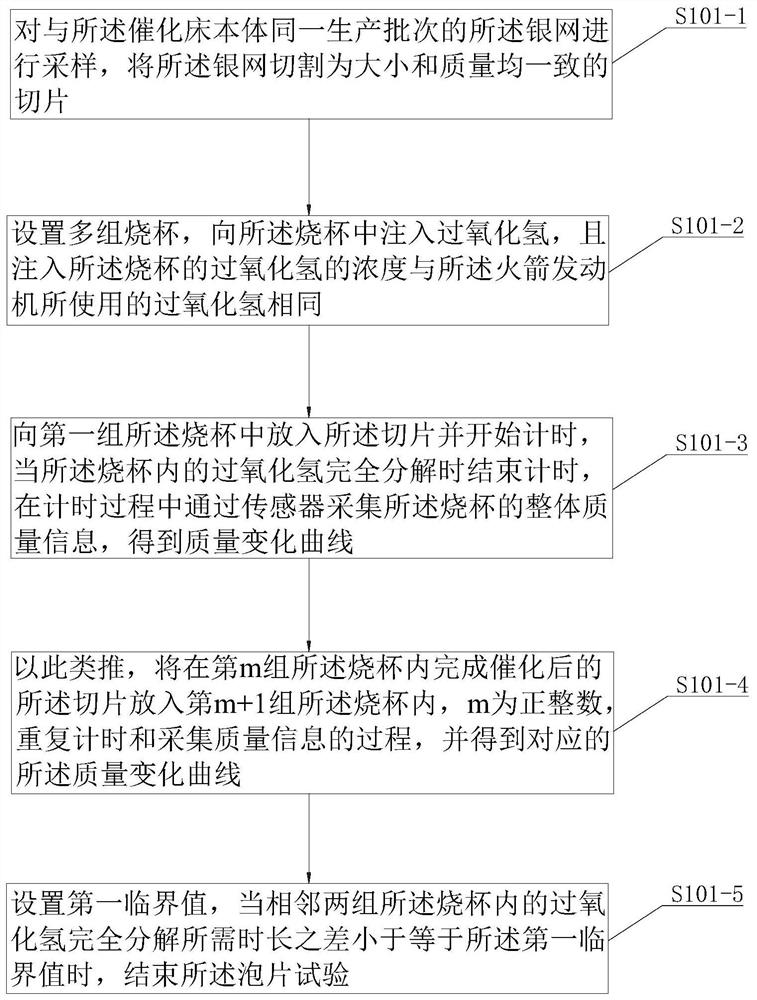

[0058] Please also refer to figure 1 and figure 2 , the present embodiment provides a method for determining the start-up scheme of the catalytic bed of a hydrogen peroxide rocket engine (hereinafter referred to as the "determination method"). For rocket engines that use different concentrations of hydrogen peroxide as the oxidant, it is possible to design a start-up scheme that matches the catalytic bed of the rocket engine in a targeted manner, improve the start-up speed of the catalytic bed, and avoid excessive ignition in the combustion chamber 3 during the ignition stage. Pressure peaks, thereby eliminating the risk of deflagration.

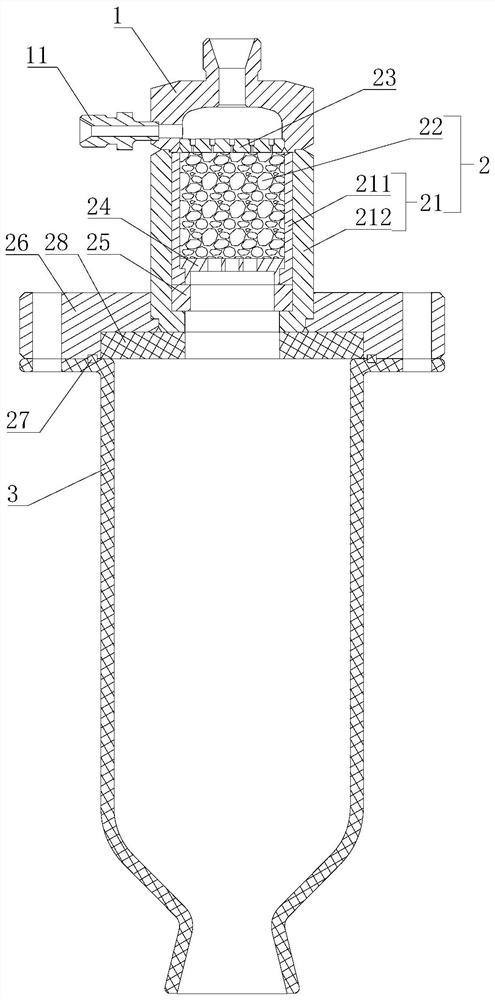

[0059] see image 3 , the rocket engine includes a head cavity 1 , a catalytic bed assembly 2 and a combustion chamber 3 .

[0060] A pressure measuring joint 11 is provided on the side wall of the head cavity 1 . The pressure measuring joint 11 is hollow and tubular and communicates with the inside of the head cavity 1 to facilitate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com